Quality Assurance in Aluminium Profile Production

In the competitive world of aluminium profile production, ensuring quality is paramount for success. But what does quality assurance truly entail in this industry?

Quality assurance in aluminium profile production involves monitoring, inspecting, and improving quality at each manufacturing stage. It ensures that aluminium products meet specific standards, from raw material inspection to final delivery, thus minimizing risks and ensuring consistency.

While understanding the basics of quality assurance offers a solid foundation, delving deeper into the processes and standards reveals the intricate details that can significantly impact production outcomes. Read on to discover the crucial stages, testing methods, and international standards that define quality in aluminium profile manufacturing.

Quality assurance reduces waste in aluminium production.True

Implementing quality assurance processes helps identify defects early, reducing waste.

Aluminium profile quality is solely judged by final delivery checks.False

Quality is assessed throughout production, not just at final delivery.

How Does Raw Material Inspection Impact Product Quality?

Ever wonder how the quality of raw materials influences the final product? Inspecting raw materials is the first step in ensuring superior product quality. It’s a critical process that sets the foundation for manufacturing success.

Raw material inspection impacts product quality by ensuring that materials meet specified standards before production begins. This early-stage verification prevents defects, enhances reliability, and maintains consistency throughout the production cycle.

The Importance of Raw Material Inspection

Inspecting raw materials at the outset allows manufacturers to verify that the components meet required specifications. For instance, in aluminium profile production1, each alloy must adhere to specific chemical and physical standards. This stage is crucial to avoid potential issues later in the manufacturing process.

Key Components of Raw Material Inspection

-

Material Certificates:

- Documents like Material Test Certificates (MTC) authenticate the properties of raw materials. These certificates are vital for verifying compliance with design requirements.

-

Physical and Chemical Analysis:

- Ensuring that physical properties (e.g., tensile strength, hardness) and chemical compositions are within specified limits is essential for maintaining product integrity.

| Property | Description | Example |

|---|---|---|

| Chemical Composition | Verifies material elements | Aluminium with 99% purity |

| Tensile Strength | Measures resistance to tension | 300 MPa for structural use |

Benefits of Rigorous Inspection

A thorough raw material inspection reduces production delays caused by non-conforming materials. By catching these discrepancies early, manufacturers can prevent costly rework or scrapping of defective products. This is especially critical in industries such as automotive and aerospace2.

Challenges in Raw Material Inspection

Despite its benefits, raw material inspection faces challenges such as:

-

Cost Implications:

- While comprehensive inspections are vital, they can be resource-intensive. Balancing costs with the depth of inspection required is a significant consideration.

-

Technological Advancements:

- Keeping up with new technologies and inspection methods is essential. Implementing advanced tools like spectrometers can enhance accuracy but requires investment.

Leveraging Supplier Relationships

Building strong supplier relationships can streamline the inspection process. Reliable suppliers often provide pre-inspected materials, reducing the need for extensive checks on-site. This collaboration fosters efficiency and trust in the supply chain.

To further explore how these practices influence quality, consider examining supply chain partnerships3. Such insights reveal how strategic collaborations enhance product quality and operational efficiency.

Material Test Certificates verify raw material properties.True

MTCs authenticate raw material properties, ensuring compliance with specifications.

Raw material inspection can eliminate all production delays.False

While it reduces delays, unforeseen issues can still arise during production.

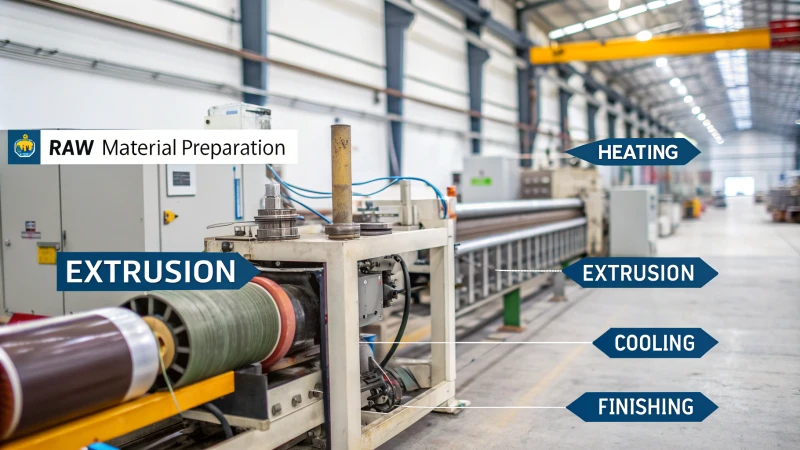

What Are the Critical Stages in the Extrusion Process?

Extrusion is a key process in manufacturing, transforming raw materials into functional products. Understanding its critical stages can optimize production and enhance quality.

The critical stages in the extrusion process include raw material preparation, heating, extrusion, cooling, and finishing. Each stage requires precise control to ensure product quality and efficiency.

Raw Material Preparation

The first stage involves selecting and preparing the right material. This ensures the extrusion process4 begins with high-quality inputs. Different materials like aluminium or plastic require specific considerations.

Heating

Next, materials are heated to a specific temperature, softening them for extrusion. This step demands precision, as overheating or underheating can affect quality.

Extrusion

In this stage, heated material is pushed through a die to form the desired shape. The die design5 is crucial, influencing the final product’s dimensions and properties.

Cooling

Once extruded, the material must cool down to maintain its shape. This can involve air or water cooling systems, each with unique benefits.

Finishing

The final stage involves cutting, machining, or applying surface treatments. This step adds value by enhancing appearance and performance.

Common Challenges

Each stage can present challenges, such as maintaining uniform heat or preventing die clogging. Engineers often use advanced technologies6 to overcome these issues and ensure optimal results.

Extrusion Stages Overview

| Stage | Key Considerations |

|---|---|

| Raw Material Prep | Quality of input materials |

| Heating | Temperature control |

| Extrusion | Die design and pressure management |

| Cooling | Method selection (air or water) |

| Finishing | Surface treatments and machining |

The success of an extrusion process lies in meticulous control across these stages, ensuring the final product meets required specifications and standards.

Raw material preparation affects extrusion quality.True

High-quality input materials are crucial for successful extrusion outcomes.

Cooling is unnecessary in the extrusion process.False

Cooling helps maintain shape and integrity of the extruded material.

Why is Dimensional and Tolerance Checking Important?

Dimensional and tolerance checking is a crucial aspect of manufacturing that ensures components fit together seamlessly, reducing errors and waste. By maintaining precise specifications, industries achieve higher quality products and improved functionality.

Dimensional and tolerance checking is essential because it ensures that manufactured parts meet specific size and shape requirements, allowing for proper assembly and function. This practice minimizes errors, reduces waste, and enhances product quality.

Ensuring Product Quality and Functionality

Dimensional and tolerance checking ensures parts conform to design specifications, crucial for product quality. Without these checks, components might not fit or function correctly, leading to costly errors.

For instance, in the automotive industry, precise tolerances7 ensure engine parts fit together perfectly, maintaining efficiency and performance. Deviations can cause mechanical failures or inefficiencies.

Reducing Waste and Costs

By catching discrepancies early in production, manufacturers can reduce waste. Fewer defective parts mean less material discarded, saving money. Consider a company producing aluminum profiles; if they don’t meet tolerance standards8, they can’t be used, resulting in significant losses.

Enhancing Safety Standards

In fields like aerospace, precise dimensions are vital for safety. Incorrect measurements can lead to catastrophic failures. For example, a minor error in a wing’s dimensions could affect an aircraft’s aerodynamics, compromising safety.

Supporting Global Industry Standards

Industry standards such as GD&T (Geometric Dimensioning and Tolerancing) provide a universal language for engineers. This ensures that products manufactured in different parts of the world can work together seamlessly.

| Aspect | Impact |

|---|---|

| Product Quality | Ensures components fit and function as intended. |

| Cost Efficiency | Minimizes waste and reduces manufacturing costs. |

| Safety | Critical in high-stakes industries like aerospace. |

| Standardization | Facilitates global collaboration and compatibility. |

Adhering to these standards, such as those outlined in GD&T guidelines9, helps maintain consistency and reliability across international manufacturing sectors. This is particularly important in industries like automotive and electronics, where precision is non-negotiable.

Dimensional checks ensure product quality and functionality.True

Dimensional checks verify parts meet design specs, ensuring quality.

Ignoring tolerance standards can increase manufacturing costs.True

Without adherence, more defective parts are produced, raising costs.

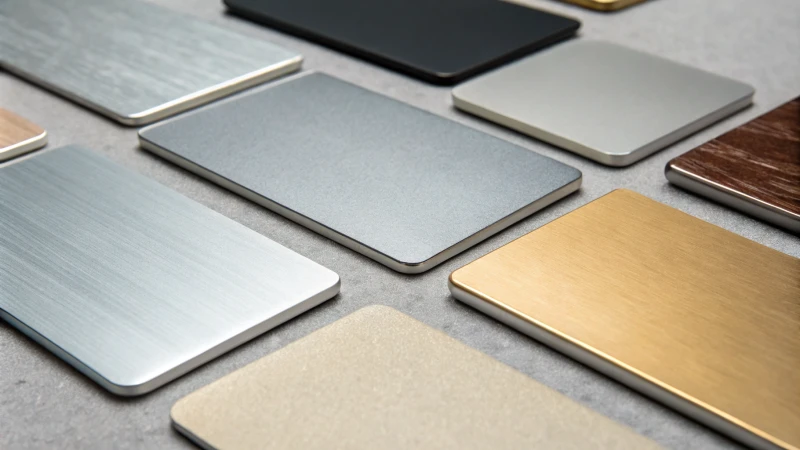

How Do Surface Treatments Affect Aluminium Quality?

Surface treatments significantly influence aluminium’s durability and appearance, impacting its quality. Understanding these effects helps manufacturers optimize performance and aesthetics for various applications.

Surface treatments like anodizing and powder coating enhance aluminium by improving its resistance to corrosion and wear, while also offering aesthetic customization. These processes are crucial for maintaining high-quality aluminium products.

Understanding Surface Treatments

Surface treatments are essential in refining aluminium’s properties. They involve processes like anodizing, powder coating, and chemical conversion, each contributing to the metal’s performance in different ways.

Anodizing

Anodizing is an electrochemical process that thickens the natural oxide layer on aluminium, enhancing its corrosion resistance and allowing for vibrant color finishes. This makes it ideal for outdoor applications10.

| Advantages | Disadvantages |

|---|---|

| Increased durability | Higher initial cost |

| Enhanced aesthetics | Limited color options |

| Non-toxic process | Requires precise control |

Powder Coating

Powder coating involves applying a dry powder to aluminium surfaces and curing it under heat. This creates a hard finish that is more resistant to chipping and scratching.

- Environmental Benefits: Powder coating emits less volatile organic compounds (VOCs) compared to liquid coatings.

- Application Flexibility: Suitable for complex geometries, providing uniform coverage.

Explore more about powder coating advantages11.

Chemical Conversion Coating

This treatment enhances paint adhesion and corrosion resistance. Commonly used as a base for subsequent painting, it ensures long-lasting paint durability.

- Zinc Chromate Conversion: Known for superior corrosion resistance.

- Non-Chromate Alternatives: Eco-friendly options are available for sustainable practices.

Learn about chemical conversion technologies12.

Comparing Surface Treatment Effects

When choosing a surface treatment, consider factors like environmental conditions, desired aesthetic outcomes, and functional requirements.

| Treatment | Corrosion Resistance | Aesthetic Flexibility | Durability |

|---|---|---|---|

| Anodizing | High | Moderate | High |

| Powder Coating | Moderate | High | High |

| Chemical Conversion | Variable | Low | Variable |

Each method offers distinct advantages, making it important to match the treatment to the specific needs of the application. For instance, anodizing13 is preferable in environments with high corrosion potential, while powder coating suits applications requiring diverse color options.

By understanding these variables, manufacturers can enhance both the functional and aesthetic quality of aluminium products. This knowledge is crucial for informed decision-making in product design and material selection.

Anodizing increases aluminium's corrosion resistance.True

Anodizing thickens the oxide layer, enhancing corrosion resistance.

Powder coating emits more VOCs than liquid coatings.False

Powder coating emits fewer VOCs compared to liquid coatings.

What Testing Methods Ensure Mechanical Performance?

To ensure mechanical performance in materials, rigorous testing methods are essential. These methods evaluate strength, durability, and reliability, crucial for industries like construction and manufacturing. Understanding these tests helps manufacturers guarantee product quality and safety.

Mechanical performance is ensured through testing methods such as tensile, hardness, fatigue, and impact tests. These standardized tests assess material strength, resistance, and durability, ensuring they meet specific application requirements.

Tensile Testing: Evaluating Material Strength

Tensile testing is a fundamental method used to determine a material’s strength and elasticity. By applying a controlled tension, it measures how much a material can stretch before breaking. Engineers rely on this test to ensure materials can withstand the expected loads and forces14.

Hardness Testing: Resistance to Surface Deformation

Hardness tests evaluate a material’s ability to resist surface indentation or abrasion. Popular methods include the Brinell, Rockwell, and Vickers tests. These are vital for applications where wear resistance is crucial, such as in construction tools15 or machinery parts.

| Method | Characteristics |

|---|---|

| Brinell | Large indentations; suitable for metals |

| Rockwell | Quick measurements; various scales |

| Vickers | Micro-indentation; precise for small areas |

Fatigue Testing: Endurance Under Repeated Stress

Fatigue testing assesses how materials behave under cyclic loading. This test is essential for components subjected to constant stress variations, like bridge structures16. It helps predict material lifespan and avoid sudden failures.

Impact Testing: Toughness Evaluation

Impact tests, such as the Charpy or Izod tests, determine a material’s toughness or energy absorption during sudden impacts. These tests ensure materials can handle abrupt forces without catastrophic failure, crucial in automotive or aerospace applications for safety17.

Tensile testing measures a material's elasticity.True

Tensile testing evaluates how much a material can stretch before breaking.

Impact tests are irrelevant for aerospace safety.False

Impact tests ensure materials can absorb energy during sudden impacts, crucial for safety.

Conclusion

Quality assurance in aluminium profile production involves systematic monitoring and inspection at each stage, ensuring product quality through raw material checks, extrusion control, dimensional accuracy, surface treatments, and mechanical testing.

-

Discover standards for aluminium alloys to ensure material quality meets industry expectations. ↩

-

Explore why rigorous quality control is crucial in high-stakes industries like automotive and aerospace. ↩

-

Learn how strategic partnerships within the supply chain enhance overall product quality. ↩

-

Learn about how raw materials are selected and prepared for extrusion to ensure high-quality outputs. ↩

-

Discover why die design is critical in shaping extruded products and its impact on quality. ↩

-

Explore advanced technologies that improve extrusion processes, overcoming common challenges. ↩

-

Learn how precise tolerances ensure the reliability and performance of automotive components. ↩

-

Explore how adhering to tolerance standards can reduce waste and save costs in manufacturing. ↩

-

Discover how GD&T guidelines standardize measurements for global manufacturing compatibility. ↩

-

Anodizing significantly improves aluminium’s resistance to weathering and UV light, making it ideal for outdoor applications. ↩

-

Powder coating offers excellent coverage on intricate shapes, ensuring a uniform and durable finish without sagging or drips. ↩

-

Non-chromate conversion coatings offer environmentally sustainable alternatives with effective corrosion protection. ↩

-

Anodizing provides superior corrosion protection by creating a durable oxide layer integral to the aluminium itself. ↩

-

Explore how tensile testing helps evaluate the material’s ability to withstand pulling forces, crucial for ensuring safety and performance. ↩

-

Learn about different hardness testing methods and their applications in evaluating material resistance to deformation. ↩

-

Understand how fatigue testing predicts the longevity of materials under repeated stress cycles. ↩

-

Discover how impact testing evaluates material toughness and its ability to absorb sudden forces. ↩