What is the difference between aluminum profile T-slot and V slot?

Are you confused about the differences between T-slot and V-slot aluminum profiles? You’re not alone!

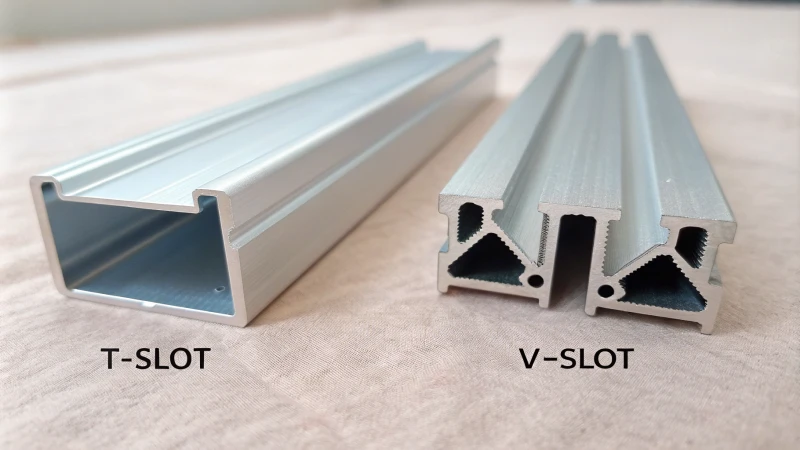

T-slot and V-slot profiles differ significantly in groove shape, applications, and hardware compatibility. T-slots feature a T-shaped groove ideal for general framing, while V-slots have a V-shaped groove optimized for linear motion systems. Understanding these differences can help you choose the right profile for your project.

Continue reading to uncover the nuances of each profile, including their specific strengths, weaknesses, and ideal applications. This detailed guide will empower you to make informed decisions for your engineering and design projects.

What are the key features of T-slot profiles?

Discover the essential features of T-slot profiles and learn why they are vital for modular construction and design.

T-slot profiles are characterized by their T-shaped groove that allows easy fastening with T-nuts and bolts. They offer excellent load-bearing capacity, flexibility for modifications, and compatibility with various hardware, making them ideal for modular applications.

1. Groove Shape and Design

T-slot profiles are defined by their T-shaped groove that runs along their length. This specific design allows for the seamless insertion of T-nuts and bolts, providing a versatile fastening system. The T-shape is particularly advantageous as it creates strong clamping forces, ensuring that components remain stable and securely fastened.

In contrast, V-slot profiles feature a V-shaped groove optimized for linear motion applications. While both profiles are modular, their groove designs cater to different functional needs.

2. Applications

T-slot profiles are widely utilized in various applications, such as:

- Modular frames for workstations

- Shelving systems

- General-purpose industrial structures

These profiles excel in environments where flexibility and ease of assembly are crucial, making them ideal for industries like automotive, construction, and automation.

| Application Type | T-Slot Profile Use | V-Slot Profile Use |

|---|---|---|

| Workstations | Commonly used | Rarely used |

| Automation Systems | Rarely used | Commonly used |

| Shelving Systems | Commonly used | Not applicable |

| Robotics | Less common | Frequently utilized |

3. Compatibility with Hardware

One of the standout features of T-slot profiles is their compatibility with a variety of hardware, including:

- T-nuts

- Bolts

- Brackets

This versatility allows for easy adjustments and modifications, making T-slot profiles suitable for projects that may evolve over time.

4. Strength and Stability

T-slot profiles are renowned for their structural strength. They can support substantial loads, making them the preferred choice for static structures, including:

- Heavy-duty machinery

- Industrial frameworks

| Profile Type | Load-Bearing Capacity | Recommended Use |

|---|---|---|

| T-Slot Profile | High | Heavy-duty applications |

| V-Slot Profile | Moderate | Light to medium-duty applications |

5. Flexibility and Ease of Assembly

Another critical feature of T-slot profiles is their modular nature, allowing for quick assembly and reconfiguration. This characteristic is essential for custom frame designs that may require adjustments in the future.

- T-slot systems are easy to machine and join, offering cost-effectiveness for various projects.

- While V-slot profiles also provide modularity, they require precise alignment with V-wheels for optimal performance, adding complexity to the assembly process.

Overall, T-slot profiles stand out in scenarios demanding both strength and adaptability, proving to be indispensable in various construction and manufacturing settings. Their design and functionality enable users to create robust structures while allowing for future modifications as needs change.

How do V-slot profiles enhance linear motion applications?

Explore how V-slot profiles revolutionize linear motion applications, offering precision and flexibility for various engineering projects.

V-slot profiles enhance linear motion applications by providing a smooth, precise path for movement through their unique V-shaped groove design, which works seamlessly with V-wheels for optimal performance.

Understanding V-slot Profiles

V-slot profiles are uniquely designed for linear motion applications, featuring a V-shaped groove that allows for the integration of V-wheels. This design facilitates smooth movement along the rails, which is crucial for applications like 3D printers, CNC machines, and robotic arms.

The compatibility of V-slot profiles with V-wheels enables a seamless sliding action, allowing components to move with precision. This capability is particularly important in systems where accuracy and repeatability are essential. For instance, in a CNC machine, the ability to achieve precise movements directly impacts the quality of the machined parts.

Benefits of V-slot Profiles in Motion Systems

One of the standout features of V-slot profiles is their versatility in various linear motion setups. The V-groove not only provides a dedicated track for wheels but also allows for easy adjustments and configurations.

Key Benefits:

- Smooth Operation: The V-groove allows for smooth and continuous motion, reducing friction and wear on components.

- Precision Alignment: The design ensures that the wheels remain aligned with the profile, enhancing the overall performance of the system.

- Customization: V-slot profiles can be adapted to a wide range of projects, from simple DIY setups to complex machinery.

| Feature | Description |

|---|---|

| Smooth Movement | Allows for minimal friction between moving parts |

| Precision Engineering | Ensures accurate alignment and positioning |

| Modular Design | Easy to integrate into various systems |

| Customizable Solutions | Flexible in adapting to project requirements |

Applications of V-slot Profiles

V-slot profiles excel in applications where linear motion is a primary requirement. Their design lends itself to several practical uses:

- 3D Printing: The smooth operation of V-wheels on V-slot profiles allows for high-quality prints by ensuring precise layer deposition.

- Robotics: In robotic arms, V-slot profiles facilitate controlled movements necessary for tasks like assembly and material handling.

- Automated Systems: Many automated systems utilize V-slot profiles to ensure efficient movement across production lines or assembly areas.

For example, in robotic assembly systems, the use of V-slot profiles can significantly enhance the speed and accuracy of operations, directly impacting productivity.

Comparison with T-slot Profiles

While both T-slot and V-slot profiles serve unique purposes in engineering applications, they are optimized for different functionalities. Below is a comparison highlighting their distinct features:

| Feature | T-slot Profile | V-slot Profile |

|---|---|---|

| Groove Shape | T-shaped groove for fastening with T-nuts | V-shaped groove for smooth linear motion |

| Primary Use | Structural applications like frames | Linear motion applications like CNC machines |

| Hardware Compatibility | Works with T-nuts and bolts | Works with V-wheels and linear motion components |

| Load Bearing Capacity | High load-bearing capacity | Moderate load capacity; designed for motion |

This comparison illustrates that while T-slot profiles are more suited for static structures, V-slot profiles are specifically engineered to enhance performance in dynamic environments where movement is essential.

Conclusion

The unique features of V-slot profiles make them indispensable in modern engineering applications that require precise movement. Their design not only promotes efficient operation but also supports the growing demand for automation and robotics in various industries. By choosing the right profile for your project, you can optimize functionality and enhance overall performance.

Which industries commonly use T-slot and V-slot profiles?

Discover the diverse industries that leverage T-slot and V-slot profiles for innovative applications.

T-slot and V-slot profiles are widely used across industries such as manufacturing, construction, robotics, and automation. Their unique designs cater to specific needs like structural strength or precise motion.

Understanding T-slot Profiles in Various Industries

T-slot profiles are renowned for their versatility, making them a staple in several sectors. Their ability to create robust structures that can be easily modified is vital in industries like manufacturing and construction.

-

Manufacturing Industry: In manufacturing, T-slot profiles are often used to build workstations and assembly lines due to their ease of assembly and reconfiguration. The capacity to support heavy machinery means they are ideal for production environments.

-

Construction Industry: Here, T-slot profiles serve in creating temporary structures and frameworks for construction sites, as they can be assembled and disassembled quickly. This flexibility is crucial for projects that require rapid adjustments.

-

Automation Sector: T-slot profiles facilitate the construction of automated systems, where they provide a reliable framework for mounting sensors and robotic components.

You can learn more about manufacturing applications of T-slot profiles.

The Role of V-slot Profiles in Specialized Applications

In contrast, V-slot profiles cater to specific needs, particularly where linear motion is essential. This makes them indispensable in industries focused on precision and automation.

-

3D Printing and CNC Machining: V-slot profiles excel in environments where precision movement is paramount. They are commonly found in CNC machines and 3D printers, allowing for smooth and controlled motion along tracks.

-

Robotics: Robotics relies heavily on V-slot profiles due to their compatibility with V-wheels, enabling robots to perform tasks that require high levels of accuracy. The modular nature allows for easy customization of robotic arms and other components.

-

Automation Systems: V-slot profiles are utilized in various automation systems where parts need to move smoothly and reliably. This includes conveyor systems and automated guided vehicles (AGVs).

Explore further on automation innovations using V-slot profiles.

Comparison of Industry Applications

To better understand how T-slot and V-slot profiles fit into various industries, the following table outlines their key applications:

| Industry | T-Slot Profile Applications | V-Slot Profile Applications |

|---|---|---|

| Manufacturing | Workstations, assembly lines | N/A |

| Construction | Temporary frameworks, scaffolding | N/A |

| Automation | Automated systems, machinery assembly | Robotics, CNC machines, 3D printing |

| Robotics | N/A | Robotic arms, guidance systems |

| 3D Printing | N/A | 3D printers |

This comparative insight helps clarify the distinct roles each profile plays across different sectors.

What factors should you consider when choosing between T-slot and V-slot?

Choosing between T-slot and V-slot aluminum profiles involves understanding their unique features and applications. Here are essential factors to consider before making your decision.

When selecting between T-slot and V-slot profiles, consider groove design, application needs, hardware compatibility, strength requirements, and assembly flexibility to make an informed choice.

When deciding between T-slot and V-slot profiles, several factors come into play. Below are key considerations to guide your decision-making process:

1. Understanding the Groove Design

The groove shape is one of the most critical aspects when choosing between T-slot and V-slot profiles. The T-slot features a T-shaped groove that facilitates easy fastening with T-nuts and bolts, making it suitable for static structures requiring high strength. In contrast, the V-slot has a V-shaped groove designed for smooth linear motion with V-wheels, ideal for applications that demand precision in movement.

For a deeper look at the advantages of groove design, check out this link: detailed analysis on groove design.

2. Evaluating Applications

| Each profile serves specific applications: | Profile | Common Applications |

|---|---|---|

| T-slot Profile | Modular frames, workstations, shelving systems | |

| V-slot Profile | CNC machines, 3D printers, robotic arms |

The versatility of T-slot makes it popular across various industries like automotive and construction, while V-slot is specialized for motion-related tasks. Understanding your project’s requirements will greatly influence your choice.

Explore more about the specific applications here: applications of T-slot vs V-slot.

3. Compatibility with Hardware

Choosing the right profile also depends on the hardware compatibility:

- T-slot works seamlessly with T-nuts and various fastening elements, providing flexibility in assembly.

- V-slot, on the other hand, pairs with V-wheels and linear motion components, making it specialized for smooth movement but less versatile for other types of connections.

Understanding hardware compatibility can streamline your assembly process. For further insights, you can read about hardware compatibility.

4. Strength and Stability Needs

Assessing the strength requirements is essential:

- The T-slot profile is known for its high structural strength, making it suitable for heavy-duty applications and static structures.

- Conversely, the V-slot profile is designed for light to medium-duty applications, where the focus is on guidance rather than load-bearing capabilities.

Check out this link for more on strength considerations in profiles.

5. Flexibility in Assembly

Lastly, consider the ease of assembly and flexibility:

- T-slot profiles allow for quick modifications, making them ideal for projects that may evolve over time.

- V-slot profiles require precise alignment with V-wheels, which can add complexity but ensure smooth operation.

For detailed assembly techniques, refer to assembly techniques.

By weighing these factors—groove design, application suitability, hardware compatibility, strength needs, and assembly flexibility—you can make an informed decision on whether T-slot or V-slot is best for your project.

Can T-slot and V-slot profiles be used together in a project?

Are you contemplating a project that combines both T-slot and V-slot aluminum profiles? Let’s explore how these two systems can complement each other effectively.

T-slot and V-slot profiles can indeed be used together in projects. Their unique designs allow for robust structural support and smooth linear motion, making them compatible when applied thoughtfully.

Understanding Compatibility of T-slot and V-slot Profiles

When considering the integration of T-slot and V-slot profiles in a project, it is essential to understand the core differences and functionalities of each. While both are designed for modular assembly, they serve different purposes and have unique design attributes.

The T-slot profile, with its T-shaped groove, is built for robust structural support, making it ideal for general-purpose frameworks. In contrast, the V-slot profile is optimized for linear motion, allowing for smooth movement along rails with V-wheels.

This fundamental difference means that while you can use T-slot and V-slot profiles together, careful consideration of their applications is necessary to ensure stability and functionality. Mixing these profiles can be advantageous in scenarios that require both structural integrity and motion capabilities.

Application Scenarios for Mixed Usage

Integrating T-slot and V-slot profiles can be particularly beneficial in projects where both static support and movement are required. Here are some examples of how they can work together:

- CNC Machines: Using T-slot profiles to create a sturdy base while implementing V-slot profiles for the moving components allows for precision engineering. Learn more about CNC setups.

- 3D Printers: A strong framework from T-slots combined with the smooth movement from V-slots can enhance the overall performance of a 3D printing setup. Discover 3D printer designs.

Design Considerations

When planning to use both T-slot and V-slot profiles, consider the following:

- Alignment: Ensure that the profiles are aligned correctly to avoid binding or misalignment during operation.

- Fastening Methods: Since T-slots utilize T-nuts for fastening, and V-slots work with V-wheels, it’s crucial to select compatible fastening systems that can accommodate both types of profiles.

| Consideration | T-slot Profile | V-slot Profile |

|---|---|---|

| Primary Use | Structural assembly | Linear motion systems |

| Fastening Mechanism | T-nuts | V-wheels |

| Strength Level | High load-bearing capacity | Moderate, for guiding motion |

| Assembly Complexity | Relatively easy | Requires alignment precision |

Potential Challenges

While using T-slot and V-slot profiles together can offer versatility, there are challenges to be aware of:

- Weight Distribution: Since T-slot profiles are more robust, ensure the weight is distributed evenly to prevent undue stress on the V-slot components.

- Dynamic Loads: Consider the type of loads that each profile will bear; dynamic loads may affect how well they work together in certain applications. Explore load distribution concepts.

In summary, while T-slot and V-slot profiles can be used together in projects, their compatibility depends on how well their respective functionalities align with the project’s requirements. This versatility offers innovative design opportunities but necessitates a thoughtful approach to assembly and engineering.

Conclusion

Learn about the key differences between T-slot and V-slot aluminum profiles, including their designs, applications, strengths, and how to choose the right one for your project.