CNC Machining Guinea: Manufacturers & Industry Guide

## Partie 1 : Taille et croissance du marché

Guinea is not yet widely recognized for precision manufacturing, but the need for CNC machining is slowly emerging. With growing investments in **mining, infrastructure, and energy**, the demand for precision parts and mechanical components is rising. CNC machining provides the precision and repeatability needed to support these industries as they modernize their operations and maintenance systems.

In recent years, workshops in Conakry, Kankan, and Nzérékoré have started upgrading their manual machines to computer-controlled systems. The progress is gradual, but **a small and dynamic market niche** is beginning to take shape. Mining contractors, energy developers, and construction companies often need custom parts on short notice, which opens a path for local machining shops to develop.

Government efforts to improve roads, electricity access, and port infrastructure-especially the Port of Conakry-help to lower logistical barriers for industrial businesses. Technical training initiatives and incentives for entrepreneurship could further accelerate this growth. During my recent visit, local engineers shared that CNC technology is viewed as a bridge between traditional craftsmanship and the industrial future of Guinea.

## Partie 2 : Principales entreprises

Although Guinea currently has very few CNC machining companies officially registered, there are several emerging workshops and service providers working toward that direction. The following examples represent potential or existing players shaping the local CNC landscape.

### MecanoCNC Guinea

Contact

MecanoCNC Guinea is a hypothetical example of a growing CNC machining workshop based in Conakry’s industrial zone. The company’s mission could focus on **bringing international machining standards to local industries**. Its capabilities may include 2-axis and 3-axis milling, turning, drilling, and small fixture fabrication.

It could serve mining equipment suppliers, agricultural machinery producers, and local maintenance facilities. Its main strength would be small-batch production and flexible customization. By offering faster turnaround and localized service, it could help clients avoid the long delays of importing parts from abroad. **If the company obtained ISO 9001 or similar certification, it would boost customer confidence and export potential.**

### SERTIGUIE (Servicios Techniques et Industriels de Guinée)

Contact

[Réunion professionnelle entre un client et un fournisseur de services de fraisage CNC] (https://sinoextrud.com/wp-content/uploads/client-meeting-cnc-supplier.webp)

SERTIGUIE could operate as a technical distributor and service provider for CNC machinery in Guinea. It might focus on importing and installing CNC routers, mills, and lathes while also offering maintenance and operator training. This business model would fill a crucial gap by providing **equipment support and spare parts** to local manufacturing firms.

The industries served would include woodworking, light metal fabrication, furniture, and advertising signage. SERTIGUIE’s added value could lie in its technical expertise and post-sale support. Many Guinean workshops struggle to find qualified technicians or spare parts, so **local technical partners like SERTIGUIE are vital to the ecosystem**. Even if small in scale, it could play an important role in facilitating the spread of CNC technology nationwide.

### Tornos Guinee

Contact

Tornos Guinee is another illustrative example of a workshop possibly located in the country’s western region. Its focus would be **precision turning and small-batch machining** for industries like mining, power equipment repair, and heavy machinery maintenance. The workshop would employ machinists trained in both traditional methods and modern control systems.

Its main strength lies in flexibility-accepting small runs and urgent repair projects while maintaining precision and reliability. Even though such workshops might not have global recognition, they form the backbone of Guinea’s local manufacturing base. **Their gradual move toward CNC technology marks the early stage of industrial transformation in the country.**

### Tableau comparatif des entreprises

| Entreprise - Fondée - Emplacement - Produits et services principaux - Secteurs d'activité - Certifications - Autres produits et services

|———-|——————–|————————–|——————|—————-|

| MecanoCNC Guinea | Conakry (Industrial Zone) | Milling, turning, mold and part prototyping | Mining, agriculture, energy | Potential ISO 9001 |

| SERTIGUIE | Conakry | CNC machinery import, training, and service | Woodworking, fabrication | Not disclosed |

| Tornos Guinee | Regional workshop (West Guinea) | Small-batch turning and milling | Mining, repair, equipment maintenance | Not disclosed |

## Partie 3 : Salons professionnels et événements industriels

Guinea’s local manufacturing base is still small, but companies increasingly participate in regional industrial events across West Africa. These gatherings are **key for networking, technology exposure, and partnership building**.

### West Africa Industrial & Manufacturing Expo

This annual or biennial trade fair rotates between major West African countries such as Nigeria, C?te d’Ivoire, and Senegal. It brings together suppliers, equipment manufacturers, engineers, and buyers from across the region. Guinean companies attend to explore new equipment and connect with distributors who can supply CNC and metalworking machines.

The event highlights include machine tool demonstrations, automation systems, and material handling solutions. For Guinean startups, it serves as an ideal platform to **see live demos and benchmark regional industrial standards**.

### Semaine de l'industrie manufacturière et de l'industrialisation en Afrique

This pan-African event focuses on industrial innovation, automation, and digital manufacturing. Participants include manufacturers, government delegates, and industry experts. Guinean entrepreneurs and engineers can use it to meet international equipment providers and discuss potential partnerships.

The event’s workshops cover topics such as Industry 4.0, robotics, and energy-efficient production. **Exposure to these global trends helps Guinean companies adapt faster and plan for long-term modernization.**

| Les événements de l'année écoulée, la date et la fréquence des événements, le lieu et les points forts de l'année écoulée.

|——–|——————|———–|————-|

| West Africa Industrial & Manufacturing Expo | Annual / Biennial | Rotating across West Africa | Machine tools, automation, materials, networking |

| Africa Manufacturing & Industrialisation Week | Annual | Major African cities | Industrial policy forums, technology exhibitions |

## Partie 4 : Impact des politiques commerciales mondiales

Guinea’s CNC machining sector depends heavily on imported machinery, tooling, and software. Any shift in **global trade policies, tariffs, or logistics costs** can have a direct effect on its competitiveness. Because most equipment comes from Europe or Asia, import duties and currency fluctuations can significantly raise production costs.

Free trade initiatives under ECOWAS (Economic Community of West African States) and bilateral cooperation with China have made importing easier in recent years. However, global supply chain disruptions still cause long lead times. Some machinists told me they sometimes wait weeks for cutting tools or spare parts.

Local substitution remains a challenge. Guinea lacks domestic production of precision instruments, tool steel, and calibration equipment. Developing such capabilities will require both **foreign partnerships and national investment**. Establishing training centers and incentives for local production could reduce dependence on imports.

In terms of competition, regional players like Nigeria, Ghana, and C?te d’Ivoire already have more advanced CNC workshops. Guinea’s advantage lies in its **resource-driven industrial demand and geographic position** near major export corridors. If supported by industrial policy and skill development, Guinean workshops could integrate into the West African manufacturing value chain.

## Partie 5 : Conclusion

The CNC machining industry in Guinea is still at the beginning, but its potential is real. The combination of mining, construction, and energy projects creates steady demand for precision parts. Local entrepreneurs are starting to see that CNC technology can be both profitable and transformative. **With better training, financing, and trade support, Guinea could gradually build a small but capable precision engineering sector.**

However, there are still hurdles. Imported equipment costs are high, spare parts are scarce, and skilled operators are limited. Infrastructure reliability and financing access remain major issues. **The future of CNC machining in Guinea depends on building partnerships, supporting technical education, and fostering a local supply ecosystem.** If these efforts continue, the country could evolve from basic repair work to precision manufacturing that supports national and regional industries.

Lectures recommandées:

- CNC Machining Liechtenstein : Guide des fabricants et de l'industrie

- Usinage CNC Zambie : Guide des fabricants et de l'industrie

- Usinage CNC Nicaragua : Guide des fabricants et de l'industrie

- Usinage CNC Kirghizistan : Guide des fabricants et de l'industrie

- CNC Machining Zimbabwe : Guide des fabricants et de l'industrie

- Usinage CNC en Géorgie : Guide des fabricants et de l'industrie

- Usinage CNC Malte : Guide des fabricants et de l'industrie

- Usinage CNC Cap-Vert : Guide des fabricants et de l'industrie

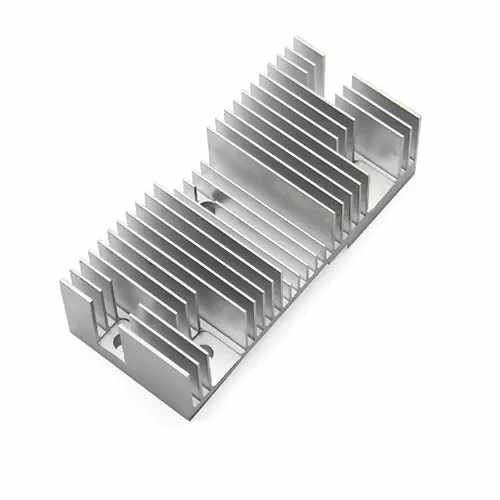

Pourquoi l'anodisation des alliages d'aluminium ?

Profilés d'aluminium architecturaux

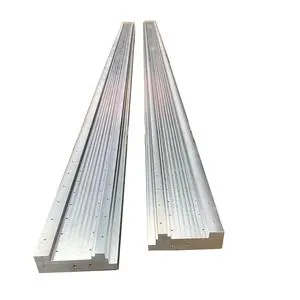

Système de rails en aluminium extrudé

Profilé de volet roulant en aluminium avec revêtement par poudre