What is 2020 aluminum extrusion?

You’ve probably seen those sleek silver rails in 3D printers and CNC machines—but what exactly are they?

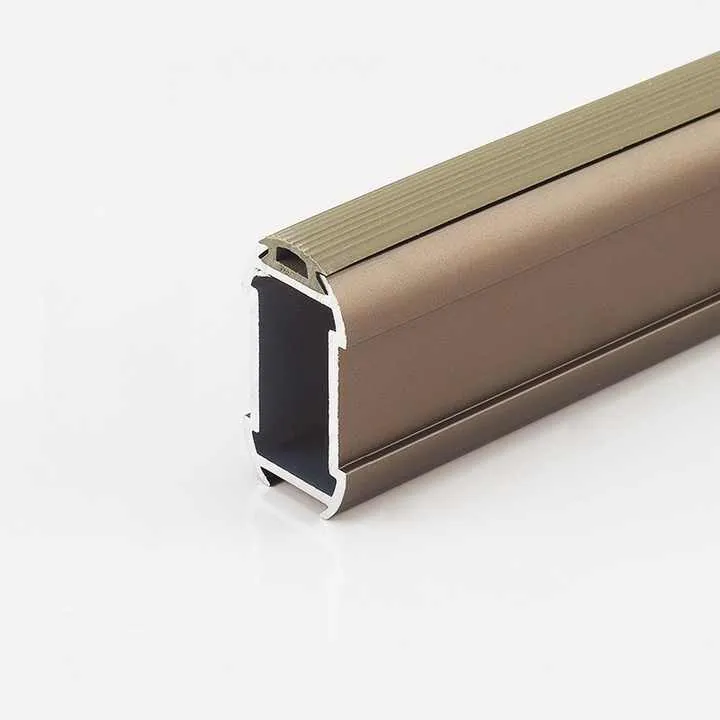

2020 aluminum extrusion is a 20mm × 20mm modular aluminum profile with T-slots on each face, used for lightweight structural frames, enclosures, and DIY builds.

It’s widely used across industries and maker projects for a reason. Let’s dive into what makes this material so versatile.

How is 2020 extrusion used structurally?

If you’re looking to build something solid without welding, 2020 extrusion is one of the best tools in your workshop.

Structurally, 2020 extrusion is ideal for lightweight frames, machine enclosures, tool carts, and support systems under moderate loads.

In my early prototyping days, I used 2020 profiles to build a custom test bench for electronics. It had to support a few kilos of tools and stay modular. Here’s what I learned.

Key structural strengths of 2020 extrusion

- Répartition de la charge: Each face of the profile has a T-slot, making it easy to attach panels or supports at any orientation.

- Modularité: You can adjust the frame size or add joints without disassembling the entire structure.

- Material strength: Made from 6063-T5 aluminum, it offers a decent strength-to-weight ratio for non-industrial loads.

Basic specifications of 2020 profile

| Propriété | Typical Value |

|---|---|

| Cross-section | 20mm × 20mm |

| Matériau | 6063-T5 aluminum alloy |

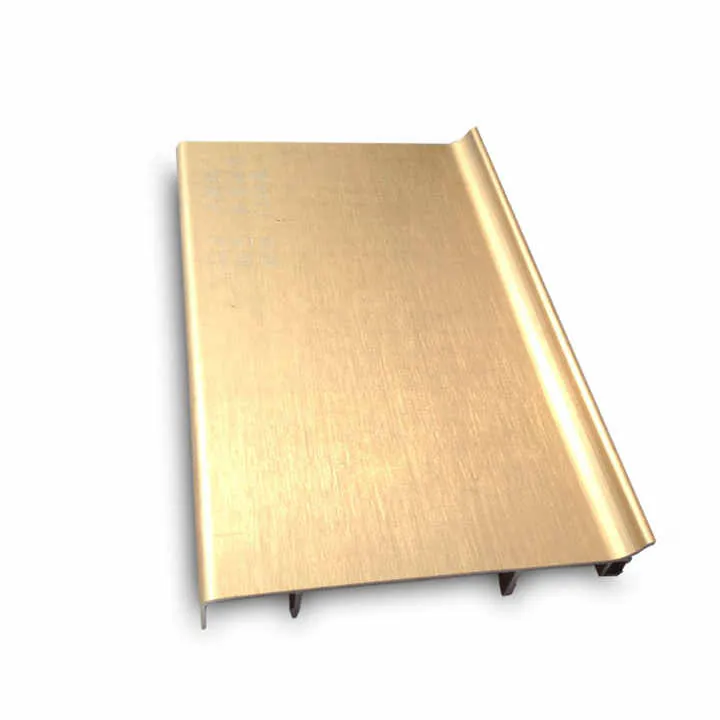

| Finition de la surface | Anodized (silver or black) |

| Poids | ~0.5kg/meter |

Application examples

- Cadres de machines

- Boîtiers d'équipement

- Display stands

- Compact shelving units

Despite its small size, when correctly braced and connected, 2020 can handle surprising loads over short spans.

2020 extrusion can be used to build structural frames for equipment like CNC routers and printers.Vrai

Its T-slot design and aluminum strength make it ideal for light to moderate structural applications.

2020 extrusion should only be used for decoration, not structural frames.Faux

It’s commonly used in structural applications such as small machinery, enclosures, and DIY carts.

Why choose 2020 for DIY builds?

Budget-conscious and beginner-friendly, 2020 aluminum extrusion checks all the boxes for personal projects.

DIYers prefer 2020 extrusion because it’s affordable, easy to cut and assemble, and compatible with a wide range of modular hardware.

I once used 2020 to build a simple desktop soldering station. No welding, just Allen keys and brackets. It was rock solid.

Benefits for DIY use

- Facilité d'utilisation: No special tools needed—just cut, bolt, and align.

- Réutilisation: Unscrew and reconfigure anytime. Ideal for testing and iteration.

- Faible coût: It’s the cheapest T-slot profile to start with.

Common DIY uses

| Project Type | Why 2020 Works Well |

|---|---|

| Imprimantes 3D | Lightweight, precise, compact |

| Machines CNC | Holds linear rails, stepper mounts |

| Furniture or desks | Easy to customize, relocate, and expand |

| Enclosures | Mount PCBs, panels, power supplies easily |

If you’re starting out or experimenting, 2020 lets you build confidently without a big budget or steep learning curve.

2020 is the most expensive aluminum profile for hobby projects.Faux

It is actually one of the most affordable and commonly used profiles in the DIY community.

Many DIY 3D printer frames are built using 2020 extrusion.Vrai

Because of its compact size and modular design, it’s widely used in open-source printer designs.

Where do 2020 profiles excel in rigidity?

Ever wondered how stiff 2020 extrusion really is? It’s stronger than it looks—especially in small-scale setups.

2020 extrusion provides excellent rigidity for small structures, especially when spans are short and loads are evenly distributed.

I’ve built light-duty test rigs and desktop shelves with this profile. No wobble, no flex—when used correctly.

Factors that enhance rigidity

- Orientation: Mounting the profile vertically gives better compression strength.

- Bracing: Diagonal braces or gusset plates reduce flex significantly.

- Joint quality: Rigid connectors, like corner brackets or internal cube connectors, improve overall stiffness.

Deflection characteristics (approximate)

| Span (mm) | Load (kg) | Deflection (mm) |

|---|---|---|

| 500 | 5 | ~0.2 |

| 1000 | 5 | ~0.8 |

| 1000 | 10 | ~1.6 |

These values assume the profile is mounted as a beam with two ends fixed. Use larger profiles (e.g., 2040 or 3030) for heavier or longer spans.

Where 2020 excels

- Enclosures

- Lightweight robotic arms

- Tabletop test setups

- Portable frames

2020 extrusion is too flexible for any load-bearing use.Faux

While not suitable for heavy industrial loads, it performs well in light structural applications with proper design.

Bracing and correct orientation significantly increase the rigidity of 2020 frames.Vrai

Using braces and understanding load directions enhances the structural integrity of a 2020 frame.

Can 2020 accessories expand functionality?

The magic of 2020 extrusion isn’t just the profile itself—it’s what you can attach to it.

T-slot accessories make 2020 extrusion one of the most flexible building systems in the world.

I’ve added hinges, wheels, handles, and even linear rails without touching a welder or drill.

Must-have accessories

- Écrous en T: Slide into the slot to anchor bolts or brackets.

- Supports d'angle: Rigid 90° connections for strong frames.

- Embouts: For safety and aesthetics.

- Sliding plates: Allow movement along the axis (used in sliders, doors).

Common upgrade examples

| Type d'accessoire | Cas d'utilisation |

|---|---|

| Linear rails | Add precision motion |

| Charnières | Create swing-out doors or panels |

| Casters | Build mobile carts or stations |

| Chaînes câblées | Manage wires along the frame |

Thanks to accessories, you can transform a simple aluminum square into a multi-functional machine frame or a production-ready tool.

Accessories like T-nuts and brackets are critical to unlocking the full potential of 2020 extrusion.Vrai

Without accessories, you lose modularity and adjustability—the main strengths of the system.

2020 extrusion can only be used with accessories from the same brand.Faux

Most 2020 accessories follow standard dimensions and are compatible across suppliers.

Conclusion

2020 aluminum extrusion is a lightweight, modular, and affordable building material perfect for small frames, hobby projects, and light industrial uses. With its T-slot system and wide accessory ecosystem, you can build practically anything—no welding or machining required.