Is this heat sink compatible with our existing mounting holes and interfaces?

Are you worried that the new heat sink won’t fit your existing hardware? You’re not alone. Many engineers face this frustrating uncertainty during upgrades or redesigns.

Yes, a heat sink can be compatible with your current setup—but you need accurate measurements and sometimes custom interfaces to ensure a perfect match.

Knowing what to measure and what to ask the manufacturer can save you time, money, and rework. Let’s go deeper into how you can make sure everything fits.

What dimensions are required to match existing mounting holes?

Many teams assume that if the heat sink looks similar, it will fit. But minor differences in hole placement can ruin compatibility.

You need to measure mounting hole spacing (center-to-center), hole diameter, and alignment type (threaded or through-hole) to ensure compatibility.

To ensure a heat sink aligns with your mounting layout, take these measurements precisely:

Key Measurements to Collect

| Dimension | Description | Pourquoi c'est important |

|---|---|---|

| Hole spacing | Distance from center to center between holes | Ensures holes align perfectly |

| Hole size | Diameter of each mounting hole | Matching screw or bolt sizes |

| Hole type | Threaded or smooth pass-through | Impacts type of fastener used |

| Position accuracy | Tolerance from CAD to physical part | Affects production consistency |

Common Mistakes

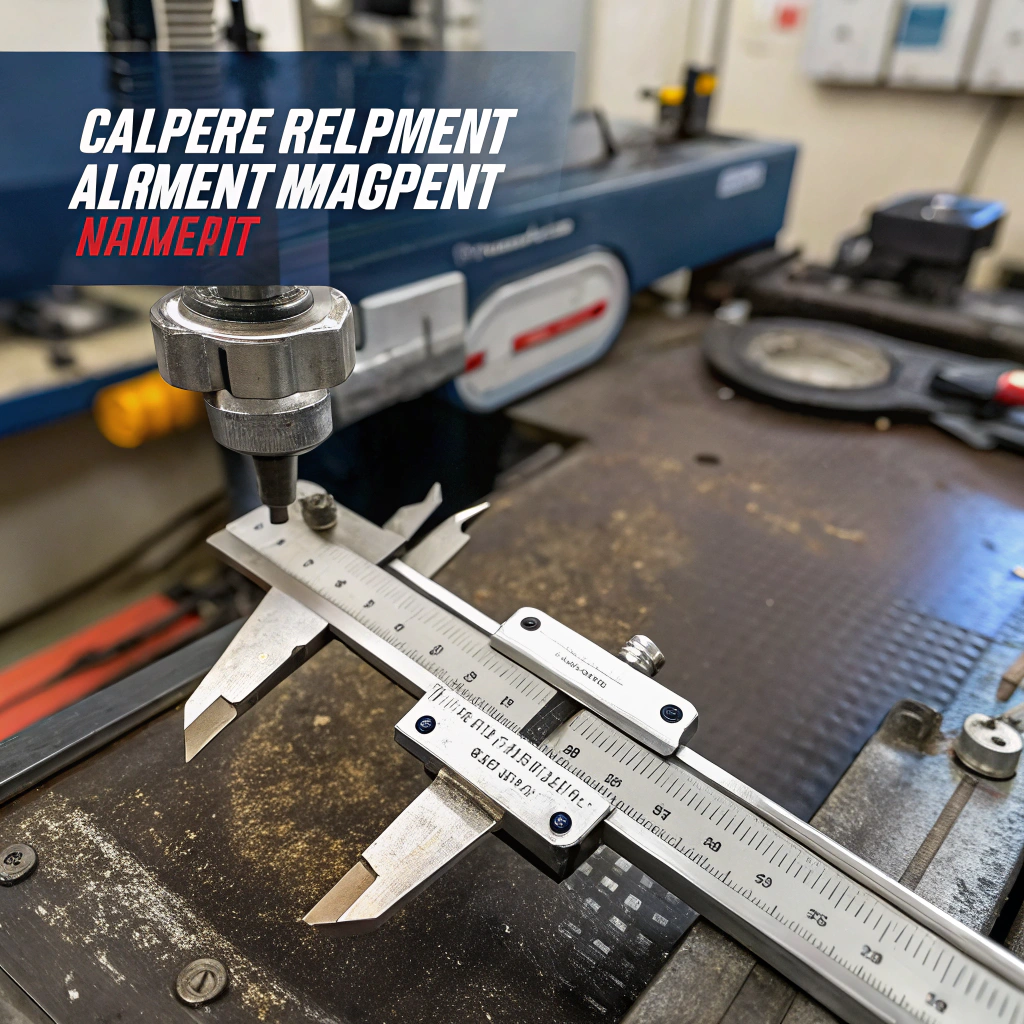

- Using visual estimation instead of calipers

- Ignoring thread type or hole depth

- Forgetting to check alignment with adjacent parts

Even a 1 mm offset can cause major alignment issues. I once worked on a power control unit where the heatsink holes were just slightly off—the technician had to re-drill the board, leading to extra labor and a broken PCB.

Accurate measurement of mounting hole spacing is essential for heat sink compatibility.Vrai

This ensures the heat sink can be mounted securely and aligns with existing hardware.

The visual similarity between two heat sinks is enough to confirm mounting compatibility.Faux

Small differences in hole location or size can lead to misalignment.

Can custom mounting interfaces be manufactured for heat sinks?

Sometimes standard heat sinks just don’t cut it. If your layout is unique, a standard model might not fit at all.

Yes, many heat sink manufacturers offer custom mounting interfaces to match your specific chassis or board design.

When your mounting pattern differs from industry norms, customization is a practical solution. Here’s what the process usually looks like:

Customization Process

| Étape | Action | Résultats |

|---|---|---|

| 1 | Submit 2D/3D drawing | Manufacturer reviews your specs |

| 2 | Design matching interface | CAD model updated with your hole layout |

| 3 | Prototype sample made | Fit is validated physically |

| 4 | Production run | Final parts delivered with custom holes |

Points to Consider

- Most manufacturers require a minimum order quantity (MOQ) for custom parts.

- The lead time for custom work may be 2–4 weeks longer than off-the-shelf options.

- Custom parts often require a setup fee for tooling or programming CNC machines.

In one of my past projects, we had to redesign the heat sink to match the new enclosure design. The manufacturer charged a setup fee but delivered perfectly drilled units in two weeks, saving us days of rework.

Heat sink manufacturers can create custom mounting hole layouts to fit specific applications.Vrai

This allows the heat sink to match unique or non-standard designs.

Custom mounting interfaces cannot be manufactured unless you order over 10,000 units.Faux

Most manufacturers accept custom orders with a much smaller MOQ, often starting at a few hundred units.

How to ensure heat sink fits our current chassis design?

Fitting a heat sink into your chassis isn’t just about holes—it’s also about clearance, airflow, and accessibility.

You need to verify both mechanical dimensions and airflow pathways to ensure a heat sink fits into your current chassis.

Here’s a step-by-step approach to validate the fit:

Step-by-Step Validation

-

Overlay CAD models

Import the heat sink drawing into your chassis model. Check for any clashes. -

Check height clearance

Make sure the top of the heat sink doesn’t interfere with other components or the chassis lid. -

Measure width and depth

Confirm there’s enough space around the heat sink for proper airflow and serviceability. -

Simulate airflow

Use CFD or simple flow arrows to ensure the air can circulate effectively through the fins. -

Test prototype

Always validate with a physical sample before committing to a production run.

Typical Pitfalls

| Enjeu | Conséquence |

|---|---|

| Heat sink too tall | Cannot close chassis lid |

| Fins block airflow | Reduced cooling performance |

| Mounting holes misaligned | Cannot fasten heat sink securely |

I recall one case where we received a bulk order of heat sinks, but the corner radii didn’t match our casing. Even though the screw holes were correct, the edges touched the wall. We had to file down 300 units by hand.

Checking heat sink height, width, and airflow is important before installation.Vrai

Ensures the heat sink physically fits and performs as expected in the chassis.

If the mounting holes align, the heat sink will always fit the chassis.Faux

Other factors like overall size and airflow also matter.

Do heat sink manufacturers support interface customization?

Many buyers worry that custom requests will be ignored or cost too much. The truth is, many manufacturers welcome this kind of collaboration.

Yes, most heat sink manufacturers offer interface customization services to meet your design requirements.

Here’s how manufacturers typically support customization:

Common Interface Options

| Interface | Customizable? | Notes |

|---|---|---|

| Mounting holes | Oui | Can match your PCB or chassis |

| Base thickness | Oui | For thermal or structural needs |

| Finition de la surface | Oui | Anodizing, powder coating, etc. |

| Fins orientation | Oui | Align with airflow direction |

Communication Tips

- Provide complete 2D and 3D drawings

- Include material preferences

- Be clear about thermal performance needs

Good manufacturers often help optimize the design. For example, I once sent over a basic sketch with a hole pattern, and the supplier came back with a full thermal simulation showing that a different fin layout would reduce hotspot temperature by 8°C. That’s true partnership.

Most heat sink manufacturers allow and support customization of interfaces.Vrai

They offer design adjustments to fit mounting, size, or thermal needs.

Manufacturers only sell standard designs and reject all custom interface requests.Faux

Most are willing to customize as long as clear specifications are provided.

Conclusion

Verifying heat sink compatibility with your existing design is not just about holes. It’s about precision, planning, and working with the right supplier. With accurate measurements and the option for customization, you can avoid surprises and ensure everything fits smoothly.

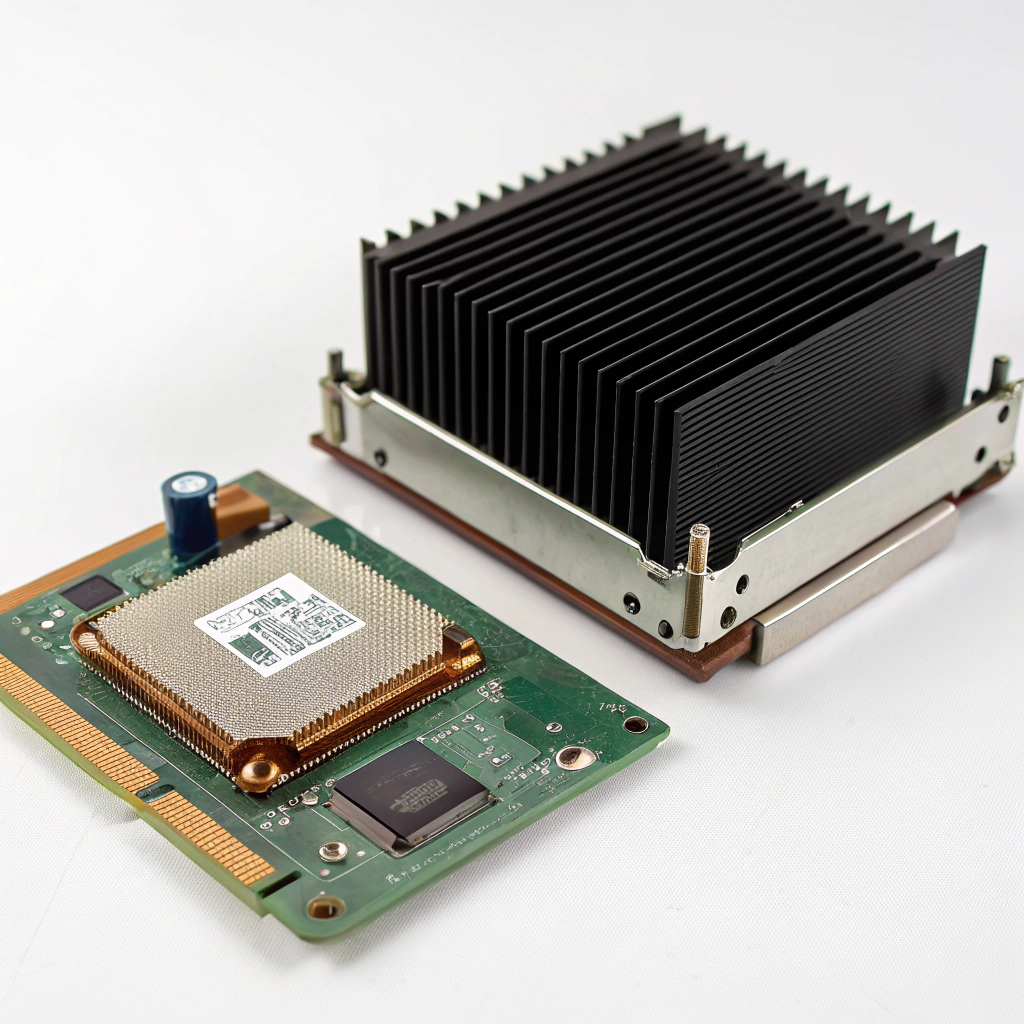

![[Product Name] by [Brand], featuring [highlighted feature] - [short usage context if applicable] Product image of a [Product Name], showcasing [key features or unique attributes]](https://sinoextrud.com/wp-content/uploads/product-image-of-a-product-name-showcasing-key-features-or-unique-attributes.webp)