What Types of Aluminum Tubes Require Bending?

Sometimes a straight tube just won’t work. I’ve faced designs needing curves, loops, or precise angles. That’s when tube bending becomes essential.

Aluminum tube bending is needed when designs call for complex shapes, tight spaces, or seamless transitions.

Keep reading and I’ll show how to pick the right bend method and ensure quality.

What Types of Aluminum Tubes Require Bending?

Tubes used in simple frames differ greatly from those used in heating systems or furniture. Not every tube bends the same.

Tubes for structural frames, fluid systems, railing, and custom profiles often require bending to meet design or installation needs.

Think about the tubes I’ve worked with:

Structural Building Tubes

Used in railings, supports, and frames. They need custom angles or curves to fit building layouts.

Fluid Transport Tubes

Used in A/C, hydraulic systems, or coolant lines. They need smooth bends to keep flow steady.

Architectural & Furniture Tubes

Used in handrails, lighting fixtures, tables. They must look good and fit design specifications.

Custom Profiled Tubes

Used for machinery guards, ergonomic handles, or complex applications. Mostly bend specialty cross-sections to precise specs.

Here is a quick overview:

| Tube Type | Utilisations typiques | Bend Needs |

|---|---|---|

| Structural Tubes | Railings, frames | Custom angles, flush installation |

| Fluid Tubes | HVAC, hydraulics, coolant lines | Smooth curves, no kinks |

| Architectural Tubes | Furniture, design fixtures | Visual quality, consistent radius |

| Profils personnalisés | Industrial or ergonomic parts | Precise curves, matching profiles |

Structural tubes often need custom bending to match building layouts.Vrai

Structural tubes like handrail supports often must bend to fit stairs, walls, and other building dimensions.

Fluid transport tubes can be bent sharply without affecting flow.Faux

Sharp bends in fluid tubes can cause turbulence, pressure drop, or blockage. Smooth radius is important.

What Bending Techniques Are Used in Aluminum Tube Services?

Getting a clean bend without flattening or wrinkling takes the right tools. Experience and technique matter — especially with aluminum.

Common techniques include mandrel bending, roll bending, press bending, and heat-assisted methods to preserve tube shape and integrity.

Here’s how those techniques work:

Mandrel Bending

Uses an internal mandrel to support the tube. Ideal for tight bends and thin-walled tubes. Prevents wrinkles and collapse.

Cintrage en rouleau

Feeding the tube between rolls creates smooth large-radius curves. Best for gentle arcs and longer lengths.

Pliage à la presse

A die presses the tube into shape. Good for simple, large-angle bends. Fast, but may need post-bend touch-up.

Heat-Assisted Bending

Applies heat to soften tube. Used for tougher alloys or complex bends. Prevents cracks and reduces spring-back.

| Technique | Meilleur pour | Avantages |

|---|---|---|

| Mandrel Bending | Tight, thin tube bends | Smooth finish, no deformation |

| Cintrage en rouleau | Large radii, longer pieces | Efficient, minimal tooling |

| Pliage à la presse | High volume, simple angles | Fast, repeatable |

| Heat-Assisted | Hard alloys, complex shapes | Prevents surface issues, precise |

Mandrel bending is best for tight, thin-walled tubes.Vrai

Internal mandrel supports the tube during bending, preventing kinks or wrinkles in tight bends.

Press bending is best suited for large-radius curves.Faux

Press bending suits single-angle bends, not smooth or large-radius curves. Roll bending is better for those.

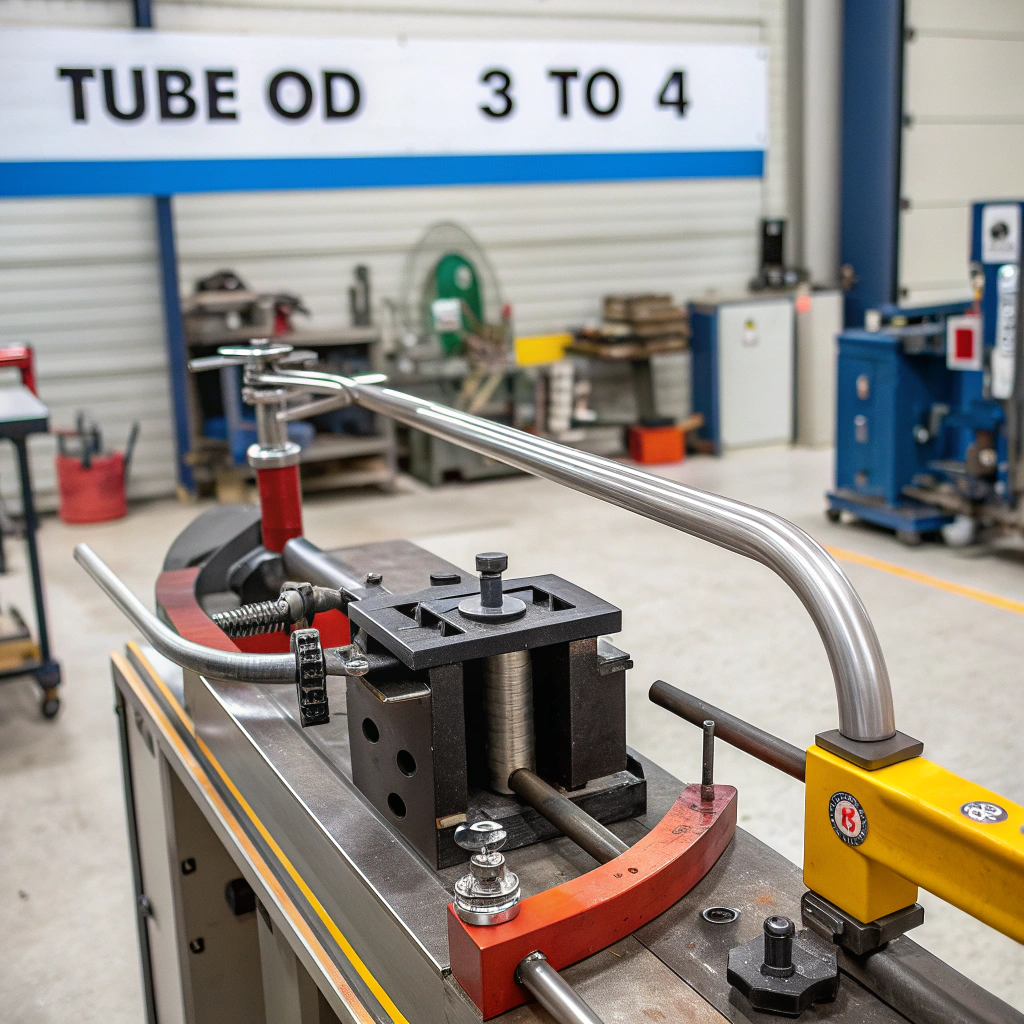

How to Calculate the Minimum Bend Radius for Aluminum Tubes?

Bending aluminum too tightly can cause kinks or cracks. The right minimum bend radius keeps the tube strong and functional.

Minimum bend radius depends on tube diameter, wall thickness, and alloy. Rule of thumb: diameter times factor like 2–4, adjusted for alloy hardness.

Here’s how I calculate it:

1. Know Tube Specs

Start by identifying the tube’s outer diameter (OD), wall thickness, and alloy type, such as 6063-T5 or 6061-T6.

2. Apply Basic Radius Rules

You can use these general formulas:

-

Pour soft aluminum alloys (e.g., 6063-T5):

Minimum Bend Radius = Tube OD × 2 -

Pour hard aluminum alloys (e.g., 6061-T6):

Minimum Bend Radius = Tube OD × 3 to 4

These provide a reliable starting point. Then refine based on wall thickness and specific bend method.

3. Adjust for Wall Thickness

Thin walls collapse more easily. Use larger radii or support tools. Thick walls handle tighter bends.

4. Consider Alloy Behavior

Harder alloys resist bending. They may need heat treatment or special dies to bend without cracking.

5. Always Test

Make a test bend and measure radius and wall deformation. Make changes if cracks or wrinkles appear.

| Grade de l'alliage | Soft/Hard | Radius Factor |

|---|---|---|

| 6063-T5 | Douceur | ×2 OD |

| 6061-T6 | Dur | ×3–4 OD |

Minimum bend radius is often set at twice the tube diameter for softer alloys.Vrai

Softer alloys like 6063 allow bends at a minimum radius of about 2× tube diameter without damage.

Hard alloys always use the same bend radius as soft materials.Faux

Harder alloys require a larger minimum radius to avoid cracking or deformation.

What Quality Checks Ensure Accurate Tube Bending?

Good bending is precise and consistent. Poor control means crooked parts or structural failure.

Quality checks include visual inspection, dimensional measurement, wall thickness check, scratch or crack detection, and fit tests against jigs or drawings.

Here’s how I ensure quality:

Inspection visuelle

Check bends for scratches, wrinkles, or paint damage. Look for surface cracks or flattening.

Contrôle dimensionnel

Measure angle, radius, and length. Compare them to design specs or templates.

Wall Thickness Check

Use ultrasonic gauge or micrometer to ensure walls did not thin out too much at the bend.

Fit and Function Test

Put bent tube into jig or assembly to check alignment, fit, and clearance.

Crack Detection

For critical parts, use dye penetrant or ultrasonic NDT to spot hidden cracks.

| Inspection Type | Tool or Method | Ce qu'il vérifie |

|---|---|---|

| Inspection visuelle | Eyes or magnifier | Surface defects, wrinkles, mishape |

| Mesure dimensionnelle | Template, protractor, caliper | Angle, length, radius accuracy |

| Wall Thickness Check | Ultrasonic gauge, micrometer | Consistent thickness at bend |

| Fit Test | Jig or assembly | Alignment, clearances, fit issues |

| NDT (Crack Detection) | Dye penetrant, ultrasound | Invisible cracks or structural faults |

Ultrasonic testing can detect wall thinning after bending.Vrai

Ultrasonic measurement helps confirm that tube wall thickness stays within tolerance after bending.

Visual inspection is sufficient to catch all defects in bent tubes.Faux

Some defects like internal cracks or delamination may not show on the surface and need NDT for detection.

Conclusion

Aluminum tube bending handles curved tubes in structures, fluids, architecture, and custom shapes. Methods like mandrel or roll bending help preserve tube strength. Calculating minimum radius uses diameter, alloy, and thickness. Plus, quality checks make sure bends stay accurate, strong, and fit properly.