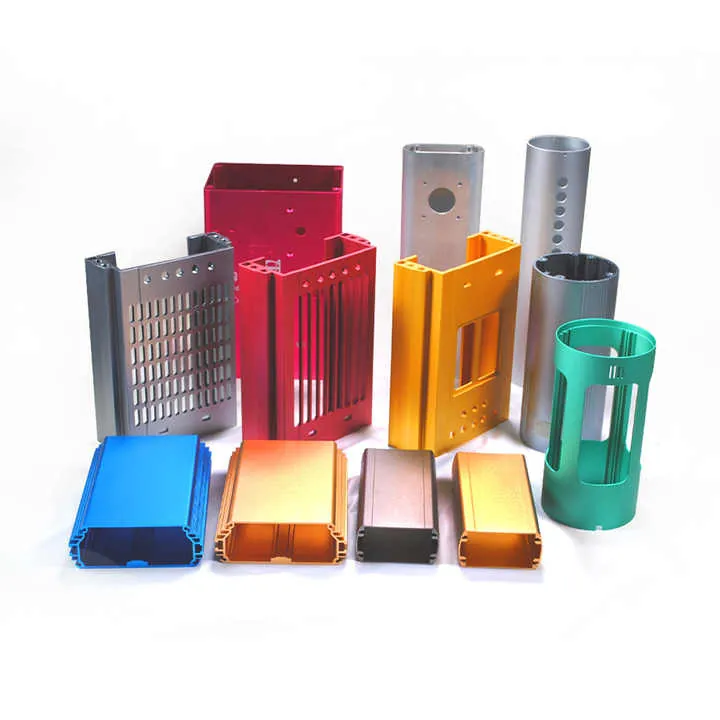

Customized Large Aluminum Extrusion Enclosure Profile: What Applications Benefit the Most?

Many industries struggle with finding protective housing that’s both strong and easy to produce. Large custom aluminum enclosures can be the answer.

Large aluminum extrusion enclosures are ideal for industries needing lightweight, strong, and heat-efficient housings—especially in electronics, energy, and transportation sectors.

If you’re unsure whether aluminum extrusions are the right fit, keep reading. You’ll discover how customizable these profiles are, and why they excel at thermal control and structural protection.

What applications benefit most from large aluminum extrusion enclosures?

Large machinery and electrical systems need sturdy covers that won’t overheat or corrode. Traditional materials like steel are strong but heavy, while plastics lack durability.

Industries like telecommunications, solar energy, automotive, and industrial automation benefit the most from these aluminum enclosures due to their size flexibility, strength, and heat performance.

These enclosures are used in:

1. Power and Energy Systems

Aluminum enclosures house power converters, inverters, and control units in renewable energy systems. Their excellent heat dissipation keeps internal electronics cool.

2. Telecommunications

Base stations and signal amplifiers use large enclosures to protect sensitive equipment outdoors. Aluminum resists corrosion from weather and radiation.

3. Electric Vehicles and Charging Stations

EV battery packs, controllers, and charging units use large aluminum extrusions for their high strength-to-weight ratio and thermal conductivity.

4. Industrial Control Systems

Factories rely on large control boxes for managing motors and sensors. These aluminum profiles offer durability and design flexibility.

| Industry | Use Case | Benefit |

|---|---|---|

| Energy | Inverter enclosures | Thermal conductivity |

| Telecommunications | Outdoor signal units | Weather resistance |

| Automotive | EV controller boxes | Lightweight, durable |

| Industrial Automation | Machine control housing | Custom sizes and sealing options |

Large aluminum enclosures are most beneficial in energy and electronics sectors.True

These sectors demand high heat dissipation, strength, and corrosion resistance—features aluminum extrusion provides.

Plastic enclosures are a better fit for heavy industrial machinery.False

Plastic lacks the necessary strength and heat resistance required for heavy-duty industrial applications.

How customizable are dimensions and shapes for enclosure profiles?

Standard enclosures don’t fit every situation. Many devices need very specific internal clearances or unique external mounting systems.

Aluminum extrusion enclosures can be customized to virtually any shape, length, or size—especially in widths over 300mm—thanks to tooling flexibility and modular design.

Customization allows clients to meet strict mechanical, environmental, or aesthetic requirements. Here’s how:

Dimensional Flexibility

You can choose wall thickness, depth, width, and extrusion length. For very large enclosures (e.g., over 300mm wide), seamless designs are possible with precise die engineering.

Structural Features

Internal channels, sliding guides, and cable raceways can be built into the profile. Extrusion allows integration of multiple functions into one part.

Modularity

Custom corner joints, mounting flanges, and bracket systems make the enclosure easy to assemble or integrate into larger machines.

| Customizable Feature | Description |

|---|---|

| Width & Height | Ranges from 10mm to over 400mm |

| Internal Tracks | For PCB slides, cable separation |

| Mounting Provisions | External flanges or grooves for wall mounts |

| Custom Ports | Extruded cable holes or sensor windows |

This flexibility supports faster prototyping and fewer secondary operations like welding or machining.

Aluminum extrusion profiles can be fully customized to specific sizes and internal designs.True

Manufacturers can design dies to match precise dimensional and structural requirements.

Extruded aluminum enclosures can only be made in standard widths and shapes.False

Extrusion allows creating custom shapes and sizes by designing unique dies.

Which surface finishes improve heat dissipation in extruded enclosures?

Electronics create heat, and too much heat reduces performance. Some surface treatments help more than others.

Anodizing, especially black anodizing, is one of the best finishes to boost heat dissipation in large aluminum extruded enclosures.

Here are common finishes that impact thermal behavior:

1. Anodizing (especially black)

This forms a porous oxide layer that not only improves corrosion resistance but increases surface emissivity. Black anodizing, in particular, radiates heat more efficiently than raw aluminum.

2. Powder Coating

It adds color and protection, but thick coatings may insulate and reduce thermal transfer. Not ideal for heat-critical systems.

3. Sandblasting + Anodizing

The rougher surface increases surface area slightly, aiding heat exchange. Combined with anodizing, this is both functional and aesthetic.

| Surface Finish | Heat Dissipation Performance | Notes |

|---|---|---|

| Raw Aluminum | Medium | Prone to corrosion |

| Black Anodized | High | Best for heat emission |

| Clear Anodized | Good | Still better than raw aluminum |

| Powder Coated | Low | May block thermal flow |

Black anodized aluminum enclosures dissipate heat better than uncoated ones.True

Black anodizing increases emissivity, enhancing thermal radiation.

Powder coating improves heat dissipation more than anodizing.False

Powder coating adds an insulating layer, which reduces thermal transfer.

What design considerations ensure optimal protection for electronic components?

Environmental stress, mechanical shock, and EMI are serious risks. A well-designed enclosure solves multiple problems at once.

Good design includes EMI shielding, gasket sealing, internal layout planning, and thermal management to protect electronic components.

Key protection features include:

1. Gasket Integration

Grooves in the extrusion allow for rubber seals. This makes the housing water-resistant and dust-proof (IP65 or above).

2. Internal Isolation

Separate compartments or mounts keep hot and sensitive components apart, reducing interference and overheating.

3. EMC Shielding

Aluminum naturally shields against electromagnetic interference (EMI), especially when enclosure seams are grounded or sealed with conductive gaskets.

4. Thermal Pathways

Designs can include heat sinks or fins as part of the extrusion to route heat away from sensitive parts.

5. Shock Resistance

Built-in structural ribs add strength. Rounded corners can deflect force and prevent stress concentrations.

| Protection Feature | Purpose |

|---|---|

| Gasketed Seams | Blocks water, dust, chemicals |

| Internal Mounting Rails | Keeps components secure |

| Grounded Aluminum Shell | Shields against EMI |

| Cooling Fins | Disperse heat away from processors |

Aluminum enclosures can provide water resistance and EMI shielding with proper design.True

Extruded profiles with gaskets and grounding features offer strong environmental and electromagnetic protection.

Aluminum enclosures cannot protect electronics from water or electromagnetic interference.False

With proper seals and design, aluminum extrusions offer excellent resistance to both.

Conclusion

Large custom aluminum enclosures are not only structurally sound but also highly customizable and thermally efficient. They’re perfect for housing modern electronics in demanding environments.