Aluminum extrusion conductivity requirements?

Electrical and thermal performance often fail in real projects. Many teams choose aluminum profiles without checking conductivity. This causes heat build up, signal loss, or safety risk. These problems are costly and hard to fix later.

Aluminum extrusion conductivity requirements depend on electrical use, thermal load, alloy choice, and surface treatment. With correct standards and alloy control, aluminum extrusions can meet both electrical and thermal needs in demanding systems.

Many buyers first focus on shape and price. Conductivity is often checked too late. This article explains how conductivity works in aluminum extrusion. It also explains how standards, alloys, and coatings affect performance in real projects.

What conductivity standards apply to electrical applications?

Electrical systems fail when conductivity is too low. This can cause voltage drop, heat, and even fire risk. Many buyers assume aluminum always works the same. This is not true.

Electrical conductivity for aluminum extrusions is usually specified as a percentage of IACS, and most electrical designs require values between 55 percent and 62 percent IACS depending on alloy and temper.

Why electrical standards exist

Electrical conductivity standards help engineers compare materials. They give a clear number instead of a guess. For aluminum, the most common reference is IACS. This scale compares materials to pure annealed copper.

Most aluminum alloys used for extrusion are not pure aluminum. Alloying elements improve strength. At the same time, they reduce conductivity. Because of this, standards matter more than marketing terms.

Common conductivity benchmarks

Below is a simple table used by many buyers and engineers.

| Material Type | Typical Conductivity (IACS %) | Common Use |

|---|---|---|

| Pure aluminum | 61 to 65 | Busbars, conductors |

| 1xxx series | 60 to 63 | Electrical profiles |

| 6xxx series | 45 to 58 | Structural and mixed use |

This table shows why alloy choice matters. A strong profile may fail in an electrical role. A high conductivity profile may fail under load.

Standards often referenced

Electrical projects often follow national or industry rules. These rules do not always name a single alloy. They define minimum conductivity or performance.

Examples include:

- Minimum conductivity for grounding systems

- Resistance limits for power distribution rails

- Heat rise limits under current load

In practice, buyers should request conductivity test data. A mill certificate alone may not be enough. Conductivity testing after extrusion gives better confidence.

Practical advice from production

In real factories, conductivity varies with process control. Extrusion temperature, quenching speed, and aging all matter. Two profiles with the same alloy can show different conductivity.

For this reason, serious electrical projects should:

- Define minimum IACS value in drawings

- Request batch level test reports

- Avoid mixing suppliers for one system

This approach reduces risk and improves long term system stability.

Electrical conductivity for aluminum extrusions is commonly specified using the IACS scale.True

IACS is the standard reference used to compare aluminum conductivity against copper.

All aluminum extrusion alloys have the same electrical conductivity.False

Different alloy series and tempers show very different conductivity levels.

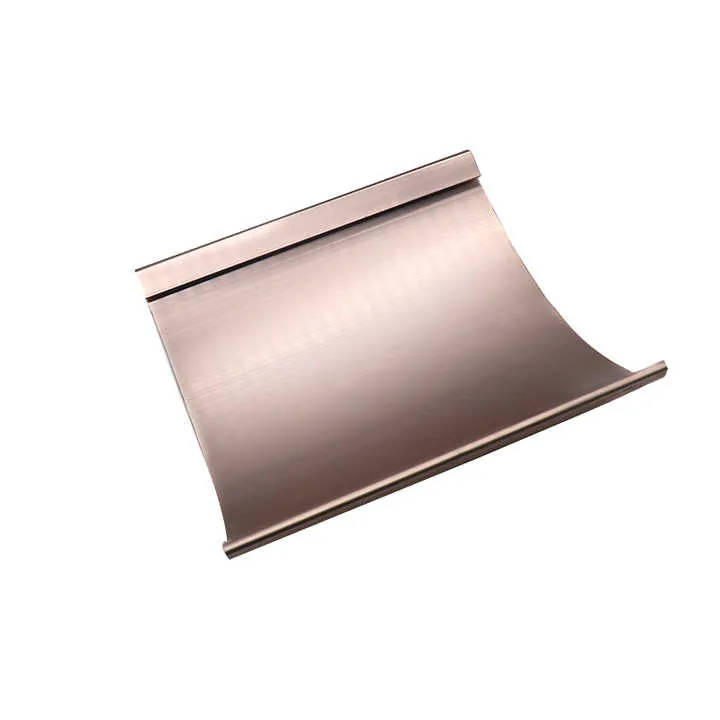

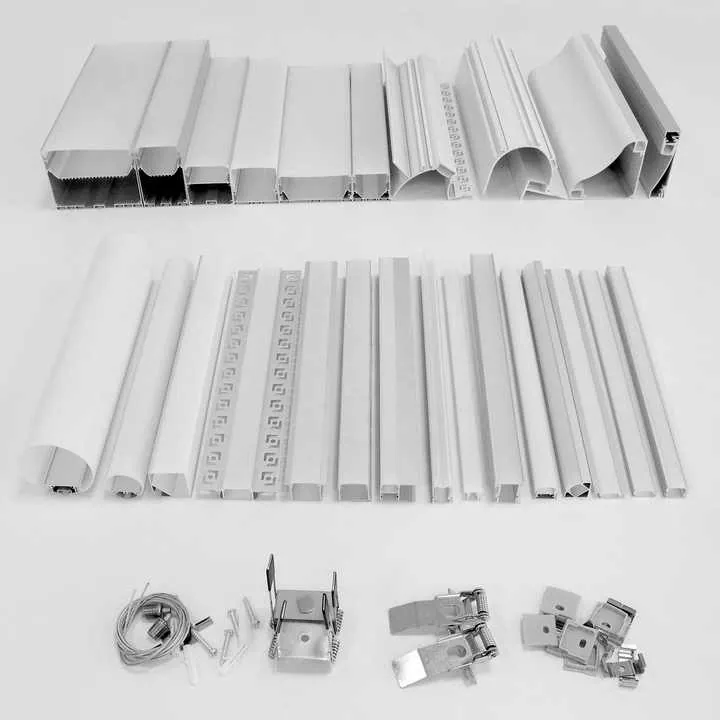

How is thermal conductivity specified for cooling components?

Cooling failure causes system shutdown. Many aluminum parts are used as heat sinks. Still, buyers often confuse thermal conductivity with electrical conductivity.

Thermal conductivity is specified in watts per meter kelvin, and aluminum extrusions used for cooling usually range from 150 to 220 W per meter kelvin depending on alloy and temper.

Understanding thermal conductivity values

Thermal conductivity measures how fast heat moves through a material. Higher values mean better heat transfer. Aluminum is popular because it balances weight, cost, and heat flow.

Pure aluminum has very high thermal conductivity. But it is soft. Structural alloys trade some thermal performance for strength.

Typical values used in design

The table below shows common reference values used by thermal engineers.

| Alloy Series | Thermal Conductivity (W/mK) | Typical Application |

|---|---|---|

| 1050 | 220 | Heat spreaders |

| 6063-T5 | 200 | LED heat sinks |

| 6061-T6 | 167 | Structural cooling parts |

These numbers are averages. Actual results depend on process and surface condition.

Design factors beyond material

Thermal conductivity alone does not define cooling performance. Shape and surface area often matter more.

Key factors include:

- Fin height and spacing

- Airflow direction

- Contact resistance at joints

An extrusion with lower conductivity can outperform a higher one if geometry is optimized.

Common buyer mistakes

Many buyers request only the alloy name. They assume it guarantees thermal results. This is risky. Heat sink performance depends on full system design.

In real projects, good practice includes:

- Asking for thermal simulation support

- Testing prototypes under load

- Avoiding over anodizing when not needed

This reduces redesign cycles and improves product life.

Thermal conductivity of aluminum extrusions is measured in watts per meter kelvin.True

This unit is standard in thermal engineering and heat transfer design.

Higher thermal conductivity always guarantees better cooling performance.False

Geometry, airflow, and contact resistance also play major roles.

Can surface coatings interfere with conductivity?

Surface treatment improves appearance and corrosion resistance. At the same time, it can reduce conductivity. This trade off is often ignored.

Surface coatings like anodizing and powder coating reduce both electrical and thermal conductivity by adding a resistive layer on aluminum extrusions.

How coatings affect electrical flow

Anodizing creates an oxide layer. This layer is hard and protective. It is also an electrical insulator. Even thin anodic films block current flow.

Powder coating adds a thicker polymer layer. This fully insulates the surface. Electrical contact must be designed around it.

Thermal impact of coatings

Coatings slow heat transfer at the surface. This does not change bulk thermal conductivity. But it affects heat release to air.

Thin clear anodizing has limited impact. Thick decorative anodizing or paint reduces cooling efficiency.

Comparison of common coatings

| Surface Treatment | Electrical Impact | Thermal Impact |

|---|---|---|

| Mill finish | None | None |

| Clear anodized | High insulation | Low to medium |

| Hard anodized | Full insulation | Medium |

| Powder coated | Full insulation | High |

This table helps buyers choose the right finish for function.

Design solutions used in practice

Engineers often mask contact areas. This allows grounding or heat transfer where needed. Another method is post machining after coating.

Good communication between buyer and extruder is critical. Surface finish should be defined with functional zones, not only color or thickness.

Anodizing creates an electrically insulating layer on aluminum extrusions.True

The oxide layer blocks electrical current flow.

Powder coating improves electrical conductivity of aluminum extrusions.False

Powder coating is a polymer layer and acts as an insulator.

Which alloys meet high conductivity requirements?

Choosing the wrong alloy causes performance loss. Many strong alloys are poor conductors. High conductivity needs clear priorities.

High conductivity aluminum extrusions usually use 1xxx or 6xxx alloys with controlled composition and temper to balance strength and conductivity.

Alloy families and conductivity

Pure aluminum conducts best. However, it lacks strength. Alloying elements reduce free electrons. This lowers conductivity.

The most common compromise is the 6xxx series. It offers good strength, corrosion resistance, and acceptable conductivity.

Common alloys used

Below is a practical comparison.

| Alloy | Conductivity Level | Strength Level | Typical Use |

|---|---|---|---|

| 1070 | Very high | Very low | Busbars |

| 1350 | High | Low | Electrical conductors |

| 6063 | Medium high | Medium | LED and frames |

| 6061 | Medium | High | Structural parts |

This table shows why no alloy is perfect for all jobs.

Temper and process control

Temper affects conductivity. Over aging reduces strength but improves conductivity. Under aging does the opposite.

Extruders adjust aging time to meet targets. Buyers should state conductivity needs early. Late changes are costly.

Real project experience

In one project, a buyer selected a strong alloy. Later testing showed excess heat. The fix required alloy change and tooling update. This delayed launch.

Clear conductivity targets at RFQ stage avoid this risk. It also helps suppliers select the right process window.

Pure aluminum alloys provide the highest electrical conductivity.True

Fewer alloying elements allow better electron flow.

Stronger aluminum alloys always have higher conductivity.False

Added alloying elements increase strength but reduce conductivity.

Conclusion

Aluminum extrusion conductivity depends on standards, alloy, temper, and surface finish. Electrical and thermal needs must be defined early. Clear specifications and testing help avoid failure and redesign.