What is 4040 Aluminium Extrusion?

Are you looking to enhance your construction or DIY project with durable materials?

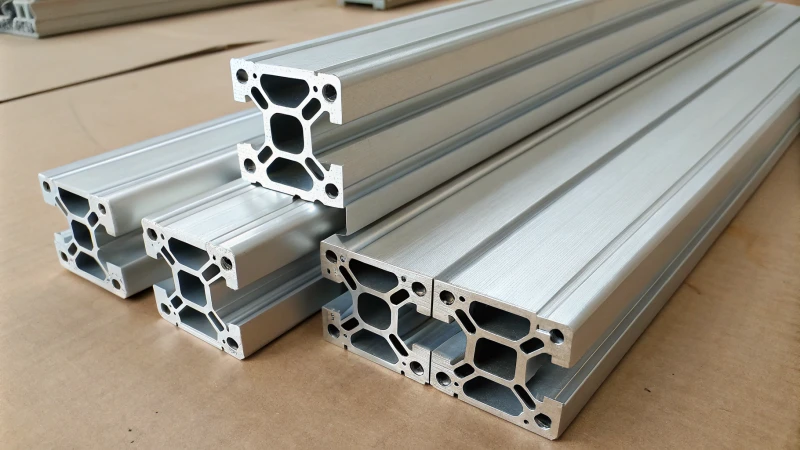

4040 aluminum extrusion is a versatile profile measuring 40mm x 40mm, widely used for creating customizable frames and structures in industrial applications. Its T-slot design allows for easy assembly, making it perfect for a variety of setups.

In this post, we’ll explore the details of 4040 aluminum extrusion, including its specifications, benefits, and how it compares to other profiles. Read on to discover how this material can elevate your projects.

What are the key dimensions and specifications of 4040 aluminum extrusion?

The 4040 aluminum extrusion is a versatile profile widely utilized across various industries. Understanding its dimensions and specifications is crucial for effective application in modular systems.

The key dimensions of 4040 aluminum extrusion are 40mm width by 40mm height, featuring a square cross-section with T-slots, making it ideal for customizable modular frames and structures.

Overview of 4040 Aluminum Extrusion Dimensions

The 4040 aluminum extrusion is defined by its dimensions of 40mm in width and 40mm in height. This square profile is designed for versatility in various applications, particularly in modular systems.

| Dimension Type | Measurement |

|---|---|

| Width | 40 mm |

| Height | 40 mm |

| Cross-section Shape | Square with T-slots |

The T-slot feature on each side allows for easy attachment of accessories and components, making it a favorite in construction and assembly tasks.

Specifications of 4040 Aluminum Extrusion

The specifications that define the performance and application of the 4040 aluminum extrusion include:

- Material Composition: Typically made from high-strength aluminum alloys, which enhances durability.

- Weight: The lightweight nature aids in handling and reduces structural load.

- Corrosion Resistance: Aluminum provides natural corrosion resistance, which can be improved further with anodization, suitable for various environments.

Load-Bearing Capacity

The load-bearing capacity of the 4040 aluminum extrusion is determined by several factors:

- Alloy Used: Different alloys have varying strength properties.

- Wall Thickness: Thicker walls can support heavier loads.

- Design Considerations: The overall design impacts how weight is distributed across the profile.

For example:

- A standard 4040 profile might handle loads up to 200 kg depending on the specific conditions and configurations used.

Common Applications

Understanding the key dimensions helps in selecting the right applications for 4040 aluminum extrusions:

- Modular Frame Systems: Ideal for creating customizable frames for workstations and machinery.

- Robotics and Automation: Frequently used in building structures for robotic arms and automated assembly lines.

- Industrial Racks: Provides strong support for shelving units and storage solutions in industrial settings.

- 3D Printer Frames: The precision and strength of the 4040 make it a popular choice for building stable frames for 3D printers.

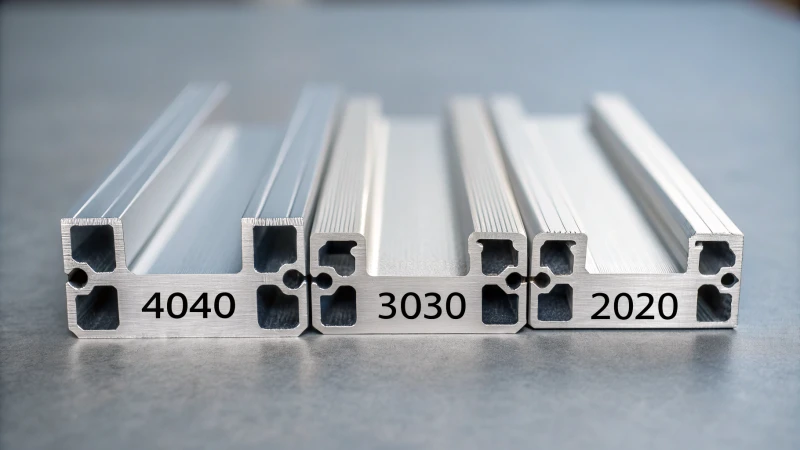

Comparison with Other Aluminum Extrusion Sizes

While the 4040 aluminum extrusion is popular, other sizes exist that serve different needs. Here’s a comparative overview:

| Profile Size | Dimensions (mm) | Common Uses |

|---|---|---|

| 2020 | 20 x 20 | Small frame applications |

| 3030 | 30 x 30 | Medium-sized structures |

| 4080 | 40 x 80 | Heavy-duty applications |

| 6060 | 60 x 60 | Large structures |

Each size has its unique advantages depending on the required application. For instance, explore the differences between these profiles to find what best suits your project needs.

How does 4040 aluminum extrusion compare to other sizes like 2020 or 3030?

When choosing between aluminum extrusion sizes like 4040, 2020, and 3030, it’s essential to consider their dimensions, load capacities, and applications to find the best fit for your needs.

The 4040 aluminum extrusion, measuring 40mm x 40mm, offers higher strength and load-bearing capacity compared to 2020 (20mm x 20mm) and 3030 (30mm x 30mm), making it ideal for heavier industrial applications.

Understanding the Dimensions and Sizes

The 4040 aluminum extrusion measures 40mm x 40mm, while other common sizes like 2020 and 3030 measure 20mm x 20mm and 30mm x 30mm, respectively.

This difference in dimensions significantly affects the applications and structural capabilities of each size.

| Profile Size | Width (mm) | Height (mm) | Common Applications |

|---|---|---|---|

| 2020 | 20 | 20 | Light frames, small machines, and enclosures |

| 3030 | 30 | 30 | Medium frames, furniture, and display stands |

| 4040 | 40 | 40 | Heavy-duty frames, automation equipment, and shelving |

As seen in the table, 4040 offers a larger cross-sectional area, making it more suitable for applications requiring greater strength.

Load-Bearing Capacity

Load-bearing capacity is crucial when comparing extrusions. The larger the profile, generally, the more weight it can support.

- 2020: Ideal for lighter structures where minimal load is expected.

- 3030: Offers a balance between weight and strength, suitable for moderate load applications.

- 4040: Provides robust support for heavier loads, often used in industrial settings.

When selecting an extrusion size, consider load-bearing factors such as wall thickness and alloy type.

Customization and Compatibility

One of the significant advantages of aluminum extrusions is their modularity. The T-slot design allows components to be easily added or removed.

- 2020: Best for small, simple structures but may not provide sufficient customization for larger frameworks.

- 3030: A versatile option that accommodates a range of attachments and accessories.

- 4040: Highly customizable with numerous connectors available for complex designs.

For more insights on compatible profiles, check out T-slot design benefits.

Cost Considerations

In terms of cost-effectiveness:

- 2020 is typically the cheapest due to its smaller size and materials.

- 3030 sits in the mid-range, balancing price with added strength.

- 4040, being the largest, usually comes at a higher price point but offers superior performance in demanding applications.

When budgeting for projects, consider not just the material costs but also long-term durability and maintenance expenses.

Conclusion on Application Suitability

While the 4040 aluminum extrusion is suited for heavy-duty applications, the selection between sizes should be based on specific project requirements. Depending on load requirements, aesthetic considerations, and budget constraints, either 2020 or 3030 may be more appropriate for lighter tasks. Understanding these differences will guide you in making an informed choice for your projects.

What industries benefit most from using 4040 aluminum extrusion?

Discover the diverse industries that reap the benefits of using 4040 aluminum extrusion in their operations.

The industries that benefit most from 4040 aluminum extrusion include manufacturing, robotics, electronics, construction, and 3D printing. Its lightweight yet strong properties make it ideal for modular systems and adaptable frameworks.

1. Manufacturing and Automation

One of the primary industries that benefit from 4040 aluminum extrusion is the manufacturing sector. These extrusions are integral in building modular workstations, automated assembly lines, and conveyor systems.

-

Strength and Modularity: The strength of the 4040 profile allows manufacturers to create durable setups that can easily adapt to changing production needs. For instance, manufacturers can utilize these profiles to design and build flexible assembly lines that can be adjusted based on production requirements.

-

Example Application: Companies in the automotive industry often use 4040 aluminum extrusions to construct customized assembly jigs that help streamline the production process.

Explore more about modular manufacturing.

2. Robotics and Automation Systems

The robotics industry also heavily relies on 4040 aluminum extrusion. The lightweight nature combined with robust strength makes it ideal for constructing frames and supports for robotic systems.

-

Versatility in Design: The T-slot design allows for easy integration of various robotic components, ensuring adaptability as technology evolves.

-

Case Study: For instance, many robotics companies use the 4040 profile to create adjustable robot arms, enhancing their efficiency and operational flexibility.

Learn more about robotics applications.

3. Electronics and Telecommunications

In the electronics sector, 4040 aluminum extrusions are often used for building racks and enclosures for sensitive equipment.

-

Durability and Cooling: Aluminum’s natural corrosion resistance helps protect electronic components, while its excellent thermal conductivity aids in heat dissipation, crucial for maintaining optimal operating temperatures.

-

Specific Use Cases: Many telecommunication companies employ these profiles in creating sturdy frames for server racks, ensuring both stability and accessibility for maintenance.

Discover electronics frameworks.

4. Construction and Architecture

The construction industry finds 4040 aluminum extrusions beneficial for a variety of applications, from creating scaffolding to designing decorative elements in buildings.

-

Lightweight Yet Strong: The lightweight nature of aluminum reduces labor costs and enhances safety during installation. Its strength allows for long spans without compromising structural integrity.

-

Architectural Applications: Architects frequently use these profiles in designing modern facades or interior partitions, where both aesthetic appeal and structural performance are paramount.

View architectural innovations.

5. 3D Printing and Prototyping

The rise of 3D printing has also led to increased use of 4040 aluminum extrusions in creating frames for 3D printers.

-

Precision and Stability: The precision-engineered profiles provide a stable platform, which is essential for producing high-quality prints. Their adjustability allows designers to tailor setups for different printing needs.

-

Industry Example: Many DIY enthusiasts and professionals in the prototyping field build their own 3D printer frames using these extrusions due to their flexibility and robustness.

Explore 3D printing applications.

Summary Table of Industries Using 4040 Aluminum Extrusion

| Industry | Common Applications | Benefits |

|---|---|---|

| Manufacturing | Modular workstations, automated assembly lines | Strength, adaptability |

| Robotics | Robot frames, adjustable setups | Lightweight, robust |

| Electronics | Racks, enclosures | Corrosion resistance, cooling |

| Construction | Scaffolding, decorative elements | Lightweight, structural integrity |

| 3D Printing | Printer frames | Precision, stability |

By exploring these industries and their applications of 4040 aluminum extrusion, we can see how this versatile material supports a variety of functions across sectors.

What are the best practices for assembling structures with 4040 aluminum extrusion?

Assembling structures with 4040 aluminum extrusion requires careful planning and execution. Here are some best practices to ensure a successful build.

To effectively assemble structures using 4040 aluminum extrusion, focus on accurate measurements, proper tool selection, and robust design planning. Ensure all components fit together seamlessly while maintaining structural integrity.

Understanding the Basics of 4040 Aluminum Extrusion Assembly

When assembling structures with 4040 aluminum extrusion, it’s essential to understand the properties and benefits of this material. The T-slot design facilitates easy joining and allows for reconfiguration. Here are some tips:

-

Select the Right Components: Choose compatible connectors, brackets, and fasteners that fit the T-slot dimensions. Use this guide to determine what works best.

-

Measure Accurately: Precise measurements are crucial. Always double-check lengths and angles before cutting the extrusion to avoid waste.

-

Use Appropriate Tools: Employ tools such as a miter saw or band saw designed for aluminum cutting, ensuring a clean edge that will fit properly in your assembly.

Planning Your Design

Before you start assembling, plan your structure thoroughly. Create a detailed design that considers:

- Weight Distribution: Ensure that heavier components are supported adequately.

- Connection Points: Identify where parts will join to maintain structural integrity.

Example Design Considerations

| Aspect | Considerations |

|---|---|

| Weight Distribution | Position heavier items at lower levels for balance |

| Connection Points | Use multiple fasteners at joints for strength |

| Adjustability | Design for future modifications or expansions |

Assembly Techniques

Several techniques can enhance the efficiency of your assembly process:

- Pre-Assembly of Sub-Assemblies: Build smaller sections of your structure first, which can simplify the final assembly.

- Use a Level: Ensure that each section is level before securing it in place. This is critical for maintaining an even structure.

Common Mistakes to Avoid

When working with 4040 aluminum extrusion, avoid these pitfalls:

- Ignoring Alignment: Misaligned components can lead to structural weaknesses.

- Over-Tightening Fasteners: This can deform the aluminum profile and reduce its strength. Refer to fastening guidelines for best practices.

Final Touches

After assembly, consider:

- Finishing Touches: Sanding rough edges and applying anodized finishes can enhance both aesthetics and corrosion resistance.

- Testing Stability: Before full use, test the stability of your structure under load conditions to ensure safety and reliability.

Where can you source high-quality 4040 aluminum extrusion locally or internationally?

Finding high-quality 4040 aluminum extrusion is essential for reliable construction and manufacturing. Here’s where you can source these materials both locally and internationally.

To source high-quality 4040 aluminum extrusion, consider local industrial suppliers, fabricators, and trade shows. For international options, explore online marketplaces and manufacturer directories.

Local Sourcing of 4040 Aluminum Extrusion

When looking for high-quality 4040 aluminum extrusion locally, start by exploring local suppliers and distributors. Many cities have specialized metal supply stores that focus on aluminum products. Here are some potential sources:

- Industrial Supply Stores: Check out local industrial supply companies that often stock various types of aluminum extrusions, including 4040 profiles.

- Local Fabricators: Reach out to fabricators who may offer custom cutting and assembly services. They can help you source the material while tailoring it to your specific needs.

- Trade Shows: Attend local trade shows focusing on manufacturing and construction materials. This is a great way to meet suppliers face-to-face and assess the quality of their products firsthand.

For an extensive directory of local suppliers, consider checking local metal suppliers that cater to businesses in your area.

International Sourcing of 4040 Aluminum Extrusion

If local options do not meet your quality standards or availability needs, looking internationally can broaden your horizons. Here are some avenues for international sourcing:

- Online Marketplaces: Websites like Alibaba or ThomasNet allow you to connect with manufacturers worldwide. You can find numerous suppliers offering 4040 aluminum extrusion in bulk.

- Manufacturer Directories: Use industry-specific directories to find international manufacturers that specialize in aluminum profiles. This can help ensure you are sourcing from reputable companies. For example, check international aluminum manufacturers.

- Import/Export Companies: Collaborate with import/export specialists who can help navigate the logistics and regulations involved in purchasing materials from abroad.

Comparing Quality and Pricing

When sourcing 4040 aluminum extrusions, it is crucial to compare the quality and pricing from different suppliers. Consider creating a comparison table:

| Supplier Name | Location | Price per Meter | Quality Rating | Lead Time |

|---|---|---|---|---|

| Local Supply Co. | South Korea | $10 | 4.5/5 | 2 weeks |

| Global Aluminum Inc. | China | $8 | 4.8/5 | 4 weeks |

| EuroMetal Works | Germany | $12 | 4.7/5 | 3 weeks |

This table helps visualize differences between potential suppliers, making it easier to make informed decisions about sourcing.

Environmental Considerations

As you explore sourcing options, consider suppliers who prioritize sustainability. Look for manufacturers that offer recycled aluminum or engage in environmentally friendly practices. This commitment to sustainability can be a significant factor for businesses like yours that value environmental responsibility.

To find eco-friendly suppliers, refer to sustainable aluminum sourcing.

Networking and Recommendations

Leveraging your network can provide valuable insights into reliable suppliers. Engage with other professionals in the outdoor equipment industry or attend relevant workshops to gather recommendations on where to source high-quality 4040 aluminum extrusions.

Joining industry forums or platforms like LinkedIn can also lead you to trusted suppliers with proven track records.

Conclusion

4040 aluminum extrusion is a 40mm x 40mm profile used for customizable frames in industrial applications, featuring T-slots for easy assembly and high strength.