Wat is de maximale grootte van het koelprofiel dat we kunnen produceren?

In large-scale industrial applications, clients often ask us: can we go wider, taller, longer? The answer depends on both design and machine.

Yes, we can produce heatsinks up to 550mm wide and 120mm tall in extrusion, depending on the press and fin complexity.

When a heatsink is too large, production becomes riskier. To make informed decisions, it’s important to understand how size affects extrusion feasibility.

What’s the largest size our heatsinks can reach?

In many projects, customers want big heatsinks—especially in energy, EV, or industrial equipment. That creates stress for the die, the aluminum, and the machines.

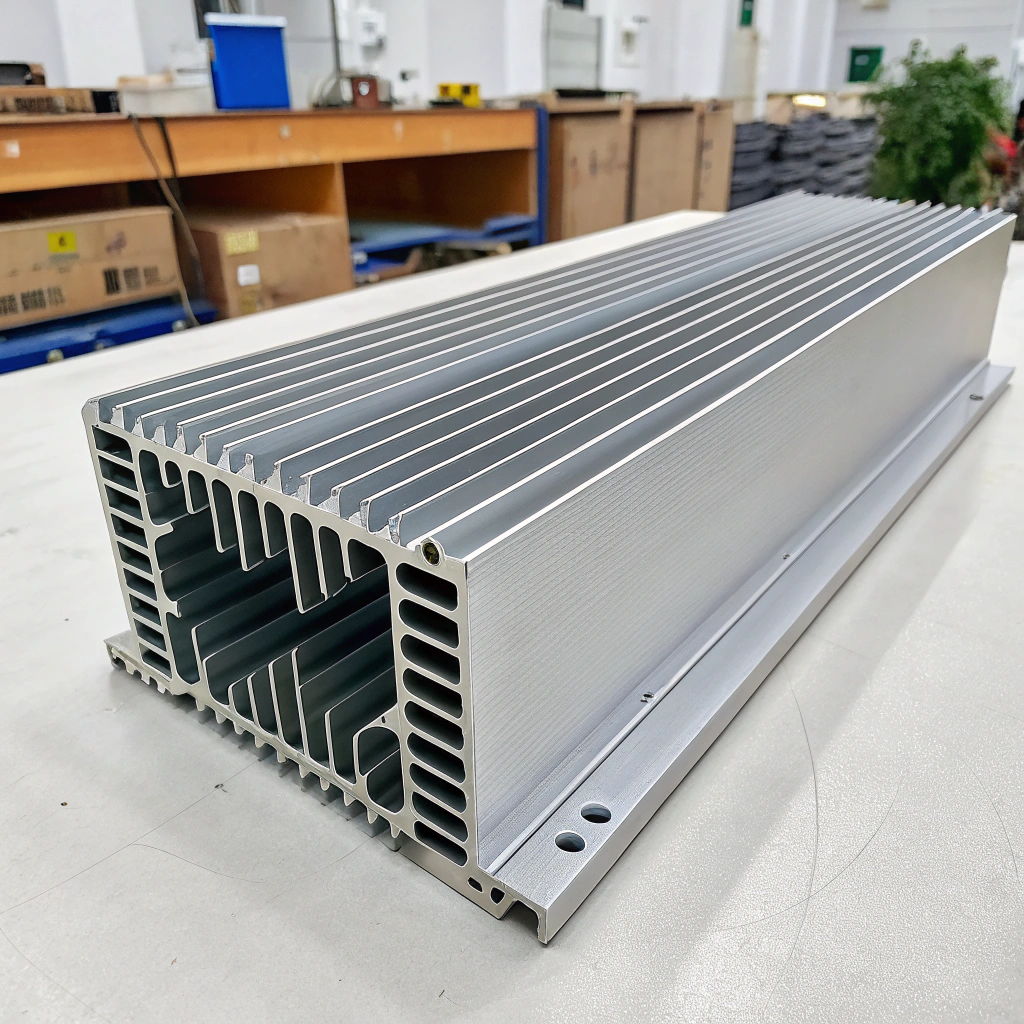

Our largest aluminum heatsink profile reached 550mm in width and 120mm in height, extruded with a 4500-ton press.

We produced this for a European customer building power inverters. The profile had high-density fins and required stable flatness on the base. We designed a custom die, optimized metal flow, and used stress-relief cooling techniques. The final product met strict tolerances.

Size Limits Overview

| Parameter | Typical Limit | Our Capacity |

|---|---|---|

| Width (Profile) | 400–500 mm | Up to 550 mm |

| Height (Fin depth) | 100 mm | Up to 120 mm |

| Lengte | 3–6 m standard, custom ok | Up to 8 m (on request) |

| Gewicht per meter | 3–10 kg/m (common) | 15+ kg/m (custom design) |

Our press range (500–4500 tons) gives us flexibility. Not every job needs maximum size. But when customers ask, we can stretch to handle large heatsinks safely.

We can extrude heatsinks with a width up to 550mm.Echt

Our largest successful heatsink extrusion to date was 550mm wide, made with a reinforced die on a 4500-ton press.

We can extrude heatsinks up to 1.2 meters in width.Vals

The extrusion width is limited by press capacity and die strength. 1.2 meters exceeds our current capability.

What length and width are supported for heatsinks?

Many clients want to know: can the heatsink be long enough to cover their device? What about wide enough to spread heat evenly?

We support heatsinks up to 550mm wide and 8 meters long, depending on weight and handling limits.

Heatsinks are shaped by the cross-section and the cut length. Here’s how it works:

Width (Cross-section)

- Maximum width is limited by the extrusion press’s container size.

- The shape must fit inside the “tool circle”—usually up to 500mm for our largest dies.

- The profile’s width includes all fins, web thickness, and base plate.

If a profile exceeds this, we suggest modular designs. For example, two halves joined by CNC or post-welding.

Lengte

- Standard bar length is 3–6 meters.

- Longer lengths are possible up to 8 meters, but handling gets harder.

- We often cut to size before machining to reduce warpage.

Long profiles are cut after extrusion, then cooled and straightened. For precision parts, we machine surfaces after cutting.

Ontwerptip

Use the full width only if necessary. More aluminum means higher cost, slower cooling, and tighter tolerances.

| Profile Parameter | Minimum | Recommended Maximum | Absolute Maximum |

|---|---|---|---|

| Breedte | 20 mm | 400–450 mm | 550 mm |

| Height (fins) | 10 mm | 100 mm | 120 mm |

| Lengte | 100 mm | 3000–6000 mm | 8000 mm |

Extruded heatsinks can be cut to any length after extrusion.Echt

Extrusion produces continuous bars that can be cut to any custom length.

The maximum possible length of a heatsink is 1 meter.Vals

Extrusion allows much longer lengths—up to 6–8 meters depending on machine and handling.

Do we have limitations on extrusion size?

Yes—size matters a lot in heatsink extrusion. We can’t push past physical and mechanical limits.

We are limited by press size, die strength, cooling control, and material flow—especially for wide or complex heatsinks.

Let me break this down simply:

1. Die and Press Size

Every extrusion press has a maximum “container diameter” (tool circle). If the profile doesn’t fit inside, it can’t be extruded.

- Our 4500-ton press handles up to 550mm tool circle.

- Die strength becomes a problem above 500mm.

- Larger presses are rare and expensive to maintain.

2. Fin Geometry

Fin spacing, thickness, and height must stay within safe limits. Extremely tall and thin fins can break the die or cause uneven flow.

- Fin height to gap ratio: try to stay under 10:1.

- Fin thickness: minimum 1.5mm for structural stability.

- Fin base must allow even flow and easy cooling.

3. Cooling and Straightness

Large heatsinks cool unevenly. That creates warping. We use:

- Water quenching

- Stretch straightening

- Aging ovens to stabilize structure

4. CNC and Machining

Bigger profiles are harder to machine. Warpage affects tolerances.

For precision surfaces, we use:

- CNC flat milling

- High-torque clamping

- Stress-relief cycles before final machining

5. Logistics

Shipping large profiles is more expensive. We offer:

- On-site packaging and protection

- Custom cut lengths

- End machining to reduce volume

If your heatsink is too big for one piece, we help split it. Either by bonding, welding, or mechanical joint design.

Larger heatsink profiles need more complex cooling and straightening procedures.Echt

Bigger profiles trap more heat and cool unevenly, which causes warping unless managed.

There are no practical size limits for extruded heatsinks.Vals

Tooling size, die limits, and machine handling all create real-world constraints on heatsink extrusion.

How does size affect production feasibility?

Going bigger sounds better—but it’s not always smarter. Bigger heatsinks create more risk, cost, and delay.

As heatsink size increases, production gets harder—costlier dies, longer cooling time, warpage, and lower yield.

Let’s break down how size affects each step:

Tooling and Die Design

| Factor | Small Profile | Large Profile |

|---|---|---|

| Die Cost | Low ($500–$1,000) | High ($3,000–$10,000) |

| Doorlooptijd | 2-3 weken | 4–6 weeks |

| Stress Risk | Laag | High—need simulation and testing |

Large dies wear faster and may crack under pressure. We run simulations before building large dies.

Extrusion and Cooling

| Factor | Small Profile | Large Profile |

|---|---|---|

| Extrusion Time | Snel | Slower extrusion, harder to push |

| Koeling | Quick air cooling | Water quenching or controlled zone |

| Warpage Risk | Laag | High—must be straightened |

Post-Processing

- Long heatsinks may bend slightly—so CNC faces must be realigned.

- Tall fins may vibrate during cutting—need careful clamping.

- Coating (anodizing, powder) must account for longer tanks or divided runs.

Material and Cost

- More aluminum = more money

- More risk = higher waste rate

- More setup time = longer lead times

When size rises, all these factors multiply.

Final Advice

Before going big:

- Ask: can we split the design?

- Ask: are tall fins really needed?

- Ask: can we optimize air flow instead?

We often help clients reduce size without losing performance. Better airflow or thicker base often beats tall fins.

Bigger heatsinks always result in lower production costs per unit.Vals

Larger heatsinks usually increase die cost, scrap rate, and cycle time, making each unit more expensive.

Designing heatsinks within standard extrusion limits improves cost and lead time.Echt

Profiles that match the press size and die tolerances are faster and cheaper to produce.

Conclusie

Large heatsinks are possible—but they come with challenges. We can extrude up to 550mm wide, but we always suggest designing within stable limits to get better cost, quality, and delivery.

![[Product Name] - [Brief Description or Main Feature] Image of [describe the product, its main features, colors, and any notable details]](https://sinoextrud.com/wp-content/uploads/image-of-describe-the-product-its-main-features-colors-and-any-notable-details.webp)