Hoe las je aluminium met een lasbrander?

Many DIYers try to weld aluminum using simple tools, but end up with weak bonds or messy results. The truth is, welding aluminum with a torch isn’t as easy as welding steel.

Yes, you can use a torch to weld aluminum, but the method is more accurately called brazing—and it requires specific tools, techniques, and materials.

Before you pick up that propane torch, make sure you know the limitations of torch welding aluminum and what alternatives exist for strong, clean bonds.

Can aluminum be torch welded?

Many beginners assume aluminum can be torch welded like steel. They try it with basic propane tools and wonder why it fails.

Technically, aluminum can be joined using a torch, but it’s usually done through brazing—not true fusion welding.

Let’s get clear on the difference: torch welding melts the base metal, while brazing melts a filler that bonds to the base metal without melting it. When using a torch on aluminum, you’re almost always brazing, unless you’re using an oxy-acetylene setup with a very fine-tuned process.

How brazing works for aluminum

To braze aluminum:

- Clean the metal with a wire brush or sanding pad.

- Heat the area with a propane or MAP gas torch.

- Apply an aluminum brazing rod once the base metal is hot enough.

- Let it flow and bond, then cool.

Key torch types for aluminum joining

| Torch Type | Suitable for Aluminum | Gebruikscasus | Opmerkingen |

|---|---|---|---|

| Propane Torch | Yes (for brazing) | DIY and light repairs | Requires aluminum brazing rods |

| Oxy-Acetylene Torch | Yes (complex welding) | Skilled welding, repairs | Hard to control; risk of melting |

| MAP Gas Torch | Yes (hotter than propane) | Faster heating for brazing | Better for thicker pieces |

Using a torch to “weld” aluminum is really about heating it just enough to melt the rod, not the base metal. Once you accept that it’s brazing—not fusion welding—you can make strong joints in many light-duty applications.

Aluminum can be properly welded using a standard propane torch.Vals

A propane torch can braze aluminum, but it can’t achieve the temperatures needed for fusion welding.

Aluminum brazing rods are designed to melt before the base metal.Echt

Brazing rods are engineered to flow and bond at lower temperatures than the melting point of aluminum.

Is brazing aluminum as strong as welding?

People often assume brazing is a “weaker” method. While that’s sometimes true, it depends on the use case and how well the job is done.

Welding aluminum is generally stronger than brazing, but brazed joints can be strong enough for many structural or functional uses.

In welding, the metals are melted and fused into a single continuous piece. This usually results in a stronger bond because the base metals are joined directly. But welding also introduces stress and requires more skill and equipment.

In brazing, the filler metal flows into the joint and bonds to the surfaces. If done correctly, this bond is durable and corrosion-resistant.

Strength comparison

| Methode | Treksterkte | Hittebestendigheid | Vaardigheidsniveau | Beste Gebruik |

|---|---|---|---|---|

| Lassen | Hoog | Zeer hoog | Hoog | Load-bearing, structural parts |

| Brazing | Middelhoog | Medium | Laag-Middelmatig | Frames, piping, DIY projects |

I once brazed two aluminum tubes for a shelving unit in my workshop. They’ve held up for over three years with no bending or corrosion. For non-load-bearing parts, brazing is often enough.

However, in aerospace or automotive industries, welding is preferred for critical parts due to its superior mechanical integrity.

Brazing always produces stronger bonds than welding.Vals

Welding usually results in stronger joints because it fuses the base metals.

Brazed aluminum can still withstand moderate structural loads if done properly.Echt

With good surface prep and clean joints, brazing can handle surprising loads.

How do you bond aluminum to aluminum without welding?

Not everyone has access to a welder or wants to deal with heat. Fortunately, there are reliable alternatives.

You can bond aluminum without welding by using adhesives, mechanical fasteners, or metal clinching techniques.

Here are the most popular ways:

1. Epoxy Adhesives

Industrial-grade epoxy can bond aluminum with excellent strength. Surface prep is critical—scuff the metal and clean it with alcohol before applying adhesive. Clamp the pieces tightly while curing.

2. JB Weld and Similar Products

Products like JB Weld are designed for aluminum and form extremely tough bonds. They’re ideal for patching holes or attaching brackets.

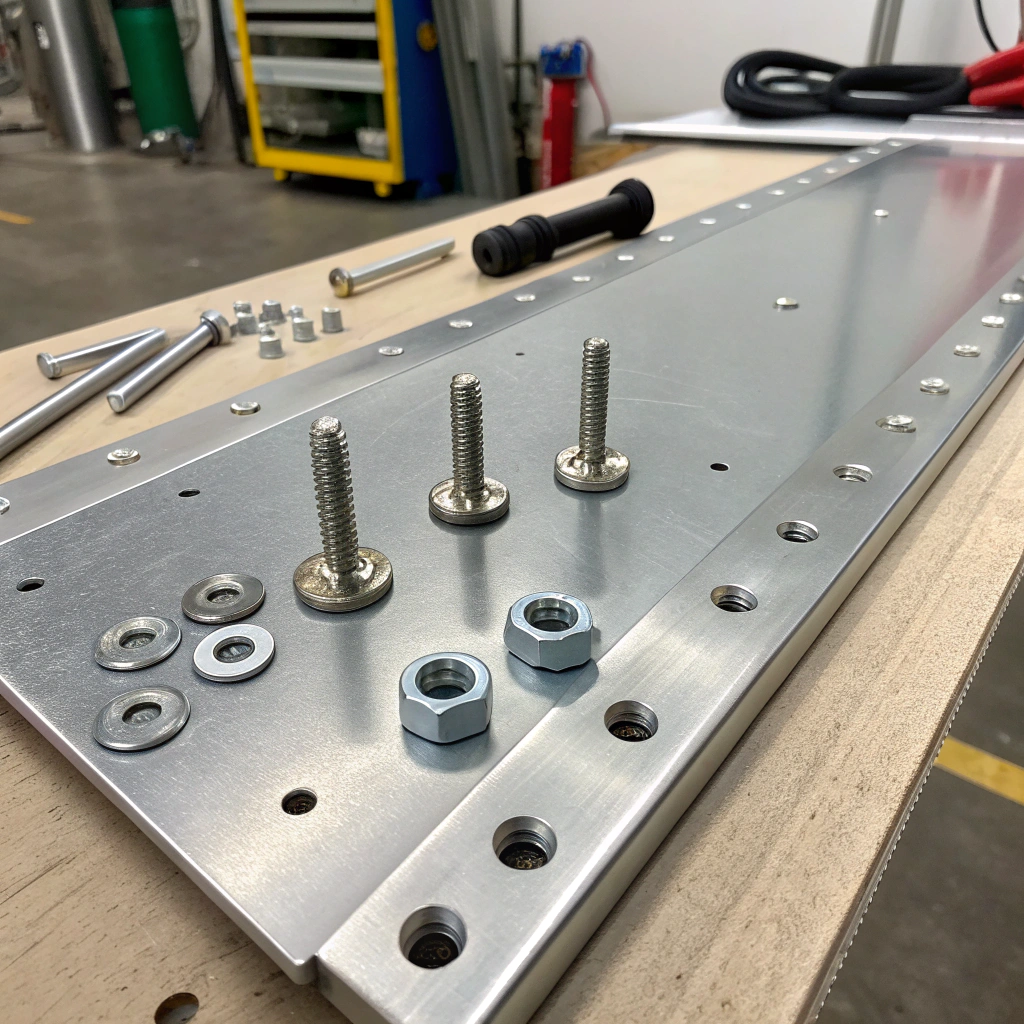

3. Mechanical Fasteners

You can use:

- Pop rivets

- Screws with washers

- Bolts and nuts

These methods are fast, durable, and reversible.

4. Clinching

A process used in industry, clinching creates a mechanical interlock between overlapping sheet metals. No heat, no adhesives, and very fast.

| Methode | Sterkte | Permanent? | Nodig gereedschap |

|---|---|---|---|

| Epoxy adhesive | Middelhoog | Ja | Clamps, applicator |

| JB Weld | Hoog | Ja | Sandpaper, applicator |

| Pop rivets | Hoog | Ja | Drill, rivet gun |

| Screws/bolts | Hoog | Geen | Drill, wrench |

| Clinching | Zeer hoog | Ja | Specialized clincher |

In one case, I needed to attach aluminum rails to a cabinet. I used epoxy and clamps—and the bond held through months of tool load and temperature shifts.

You can bond aluminum without using heat or welding tools.Echt

Epoxy, rivets, and clinching are common methods that don’t require heat.

Clinching is a temporary method for bonding aluminum.Vals

Clinching creates a permanent, high-strength mechanical interlock.

What gas to use when welding aluminum?

If you decide to step up from torch brazing and move to proper aluminum welding, gas choice becomes critical.

Pure argon is the standard shielding gas for welding aluminum. Helium or argon-helium mixes are used for thick materials.

In both MIG and TIG welding, shielding gas prevents contamination and oxidation during welding. Aluminum reacts quickly with air, so you need an inert atmosphere.

Common shielding gases

| Gas Type | Beste voor | Opmerkingen |

|---|---|---|

| 100% Argon | Thin aluminum (<¼ inch) | Clean arc, easy start, common |

| Argon/Helium Mix | Thick aluminum (>¼ inch) | Hotter arc, deeper penetration |

| 100% Helium | Rare, thick work only | Expensive, hard to start arc |

Argon provides the smoothest arc and is easy to control, which is why it’s used in most aluminum welding applications. Helium increases heat, which helps on thick pieces, but it’s more expensive and requires higher voltage.

Recommended gas settings by method

| Welding Method | Gas Type | Flow Rate (CFH) |

|---|---|---|

| TIG | 100% Argon | 15-20 |

| MIG (thin) | 100% Argon | 20-30 |

| MIG (thick) | Argon/Helium Mix | 30–40 |

Argon gas is suitable for both MIG and TIG aluminum welding.Echt

Pure argon is the most commonly used shielding gas for aluminum in both MIG and TIG.

Carbon dioxide is a safe and effective gas for aluminum welding.Vals

CO₂ reacts with aluminum and causes contamination; it's not used for aluminum welding.

Conclusie

Torch welding aluminum is more accurately called brazing—and it works well with the right tools and knowledge. Whether you’re bonding with heat, glue, or rivets, there are several ways to connect aluminum safely and effectively—even without a welder.