Aluminium extrusie voor industriële behuizingen?

Aluminum extrusion is becoming a top choice for industrial enclosures due to its exceptional durability, lightweight properties, and versatility. Are these the reasons why it is ideal for your needs?

Aluminum extrusions offer a robust solution for protective enclosures, combining strength, lightness, and adaptability. Their corrosion resistance and customizable profiles make them an excellent choice for many industrial applications.

But what makes aluminum extrusion stand out among other materials? Let’s take a deeper look at why it’s the ideal material for industrial enclosures and how it benefits various sectors.

Why Are Extrusions Ideal for Protective Enclosures?

Looking for a material that ensures maximum protection for your equipment? Aluminum extrusions might be the perfect solution due to their inherent properties that offer durability and adaptability.

Extrusions are ideal for protective enclosures because they are strong, lightweight, and highly customizable. Their resistance to corrosion and high thermal conductivity make them perfect for safeguarding electronic equipment.

Aluminum extrusions are preferred in the manufacturing of protective enclosures because they combine a series of advantages that are essential for industrial use. One of the key reasons for choosing aluminum is its corrosion resistance. When used in industrial environments, equipment is often exposed to harsh conditions, including moisture and chemicals. Aluminum naturally forms a protective oxide layer on its surface, preventing further corrosion. This means that even after years of use, an aluminum enclosure will maintain its integrity and perform as expected.

Furthermore, aluminum has an excellent strength-to-weight ratio. Unlike steel, which is both strong and heavy, aluminum provides the same level of strength but at a fraction of the weight. This is particularly beneficial in industries where mobility or space-saving design is a concern, such as in electronics or telecommunications.

Another important factor is thermal management. Aluminum has excellent thermal conductivity, meaning it can effectively dissipate heat generated by the equipment inside the enclosure. This makes aluminum extrusions ideal for housing electronic components that generate heat, such as circuit boards or power supplies. The material helps maintain optimal temperature levels, reducing the risk of overheating and damage to sensitive components.

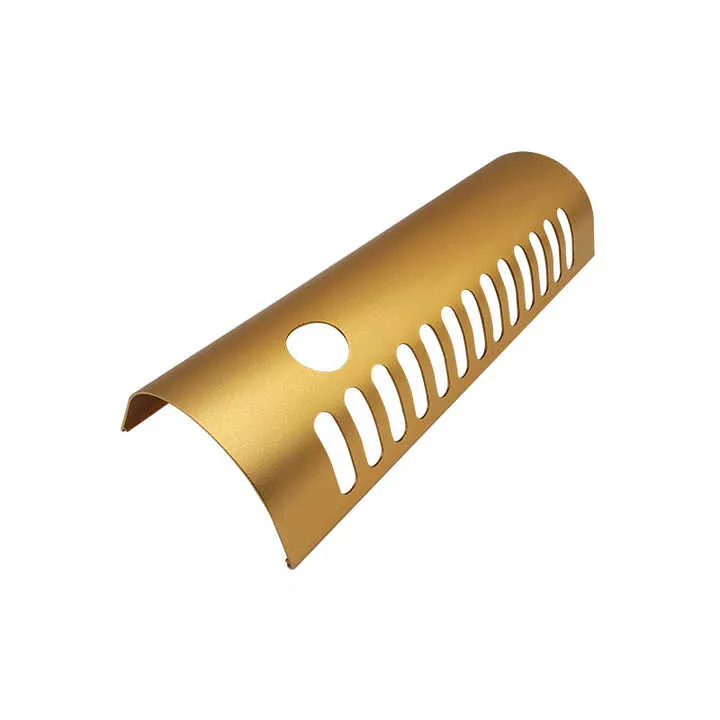

The extrusion process itself also adds significant value. Aluminum extrusions are created by forcing heated aluminum through a die to form specific profiles. This allows for an incredibly wide range of designs, ensuring that the enclosures are tailor-made for specific requirements. Whether it’s adding mounting points, ventilation slots, or other features, the versatility of aluminum extrusion makes it easy to customize.

Finally, extrusions can be easily fabricated, which lowers production costs for custom enclosures. The process is efficient and scalable, making it possible to produce large quantities of enclosures quickly and at a lower cost. This is particularly important for industries where cost-effective, high-quality solutions are needed for mass production.

Aluminum extrusions are resistant to corrosion, lightweight, and offer superior thermal conductivity.Echt

These properties make aluminum extrusions ideal for protective enclosures.

Aluminum extrusions are less customizable compared to other materials.Vals

The extrusion process offers a high degree of customization, allowing for tailored profiles and features.

Which Profiles Enable Modular Enclosure Design?

Do you need flexibility in your enclosure designs? Modular designs are made easier with aluminum extrusion profiles that allow for scalability and ease of modification.

Modular enclosure designs benefit from a variety of profiles, including U-shaped, L-shaped, T-shaped, and rectangular profiles. These allow for easy expansion and reconfiguration without custom manufacturing.

Aluminum extrusions provide the building blocks for modular enclosure designs, which offer great flexibility for future expansions or reconfigurations. When creating modular enclosures, profiles such as U-shaped, L-shaped, T-shaped, and rectangular channels are most commonly used. These profiles provide a variety of options for assembling enclosures of different sizes and shapes, without requiring complex tooling or custom manufacturing.

One key benefit of modular designs is the ease with which enclosures can be reconfigured. For instance, an L-shaped extrusion can be used to form a corner or a structural joint in the enclosure. U-shaped extrusions can form protective walls or frames, while T-shaped profiles are often used to create attachment points for additional components. These versatile profiles make it easy to expand or reduce the enclosure size depending on the needs of the application.

Another advantage is the ability to create enclosures with different mounting and integration options. For example, a rectangular profile with mounting holes can be used to securely attach equipment or brackets. This modularity allows users to design enclosures that can house a wide range of equipment, from sensitive electronics to more rugged industrial machinery.

Modular designs are also cost-effective. Because the same profiles can be used in a variety of configurations, manufacturers can stock fewer parts while maintaining a high level of flexibility. This leads to reduced lead times and lower production costs, which can be critical for industries where time and cost efficiency are crucial.

In addition, modular enclosures are often easier to assemble and modify. With fewer custom parts required, manufacturers can quickly change designs, making it possible to adapt to new requirements without going through a lengthy redesign process. This is especially beneficial in industries with rapidly changing technology or customer demands.

Modular designs allow for quick assembly and easy customization of enclosures.Echt

Profiles like U-shaped, L-shaped, and T-shaped offer flexibility and scalability for modular enclosures.

Modular designs require complex custom tooling and are difficult to modify.Vals

Modular designs benefit from standard profiles that can be easily assembled and modified with minimal tooling.

Can Extrusions Offer EMC Shielding Options?

Are you concerned about electromagnetic interference (EMI) affecting your sensitive equipment? Aluminum extrusions provide excellent options for EMC shielding, which is essential for maintaining device performance in challenging environments.

Aluminum extrusions offer reliable EMC shielding solutions due to their conductive properties. They can be designed to block or absorb electromagnetic interference, protecting sensitive electronic equipment.

Electromagnetic Compatibility (EMC) is crucial for protecting electronic equipment from unwanted electromagnetic interference (EMI). Aluminum extrusions play a significant role in providing effective EMC shielding due to their inherent conductive properties. By using aluminum as a material for enclosures, manufacturers can shield sensitive electronics from external interference and prevent internal components from emitting harmful electromagnetic radiation.

The shielding effectiveness of aluminum extrusions depends on several factors, including the thickness of the material, the design of the extrusion profile, and any additional features like conductive gaskets or metal inserts. The extrusion process allows for creating profiles that can integrate these additional shielding components. For example, conductive gaskets can be incorporated into the extrusion profile to form a seal that blocks EMI. This provides a more complete shielding solution that is both efficient and cost-effective.

In addition to shielding external EMI, aluminum extrusions can also prevent internal electromagnetic emissions. Many electronic devices, such as computers, medical equipment, and communication devices, need to comply with strict regulations regarding electromagnetic emissions. Aluminum enclosures can help meet these standards by containing the electromagnetic radiation generated by the equipment.

Another important aspect of EMC shielding is the material’s grounding capabilities. Aluminum’s high conductivity ensures that it can effectively ground any electromagnetic charges that may accumulate on the surface of the enclosure. This grounding helps to disperse unwanted electromagnetic energy, reducing the risk of damage to sensitive components or interference with other equipment.

Moreover, aluminum extrusions can be designed with various thicknesses and profiles to meet specific EMC requirements. Whether it’s a simple shielding application or a more complex design requiring multi-layer protection, aluminum extrusion offers the flexibility to meet these demands.

Aluminum extrusions can offer effective EMC shielding solutions through their conductive properties.Echt

Aluminum's conductivity allows for effective EMI blocking and grounding.

Aluminum extrusions cannot be used for EMC shielding.Vals

Aluminum is widely used for EMC shielding due to its ability to block and absorb electromagnetic interference.

What Standards Apply to Industrial Housing?

Are there specific standards that apply to industrial enclosures? Yes, there are several important standards that guide the design and performance of enclosures, ensuring safety and functionality.

Industrial enclosures must comply with various standards, such as IP ratings for ingress protection and IEC 60529, which outlines the protection levels against dust and water.

When designing industrial enclosures, compliance with standards is crucial to ensure safety, reliability, and functionality. One of the most important standards for enclosures is the Ingress Protection (IP) rating system, which is used to define the level of protection an enclosure offers against dust and water. The IP rating consists of two digits: the first digit represents protection against solid objects (such as dust), and the second digit represents protection against liquids (such as water). For example, an enclosure with an IP67 rating is completely dust-tight and can withstand submersion in water up to a certain depth.

In addition to the IP rating, enclosures must also comply with the IEC 60529 standard, which specifies the requirements for ingress protection. This standard outlines the testing methods and performance criteria for different protection levels, ensuring that enclosures meet the necessary safety and durability standards for various environments.

Other important standards that apply to industrial enclosures include UL (Underwriters Laboratories) certifications for safety, which are essential for ensuring that the enclosures are safe for use in specific industries. Depending on the application, enclosures may also need to meet CE (Conformité Européene) standards for products sold in Europe, indicating compliance with health, safety, and environmental protection regulations.

Moreover, industrial enclosures often need to meet specific industry requirements related to the environment in which they will be used. For example, enclosures used in hazardous locations must comply with standards such as the ATEX directive, which governs the safety of equipment used in explosive atmospheres.

By adhering to these standards, manufacturers ensure that their enclosures are not only functional but also meet the necessary safety requirements for the specific industries they serve.

Industrial enclosures must meet various standards such as IP ratings and IEC 60529 for safety and protection.Echt

These standards ensure enclosures provide appropriate protection against dust, water, and other environmental factors.

Industrial enclosures are not required to comply with any safety or protection standards.Vals

There are several standards, such as IP ratings and IEC 60529, that ensure enclosures provide the necessary protection for various industrial applications.

Conclusie

In conclusion, aluminum extrusions offer numerous advantages for industrial enclosures, including customization, durability, and efficient shielding. Their flexibility, along with compliance with safety standards, makes them the go-to solution for a wide range of applications.