What is the thermal conductivity of your heat sink in W/m·K?

Confused by all the thermal numbers on heat sink specs? You’re not the only one. Many buyers don’t understand what W/m·K means or why it matters in real-world use.

The thermal conductivity of aluminum heat sinks typically ranges from 150 to 235 W/m·K, depending on alloy and treatment.

But that number alone doesn’t tell the full story. Let’s break it down and understand what really affects thermal performance.

How is the heat sink’s thermal performance tested?

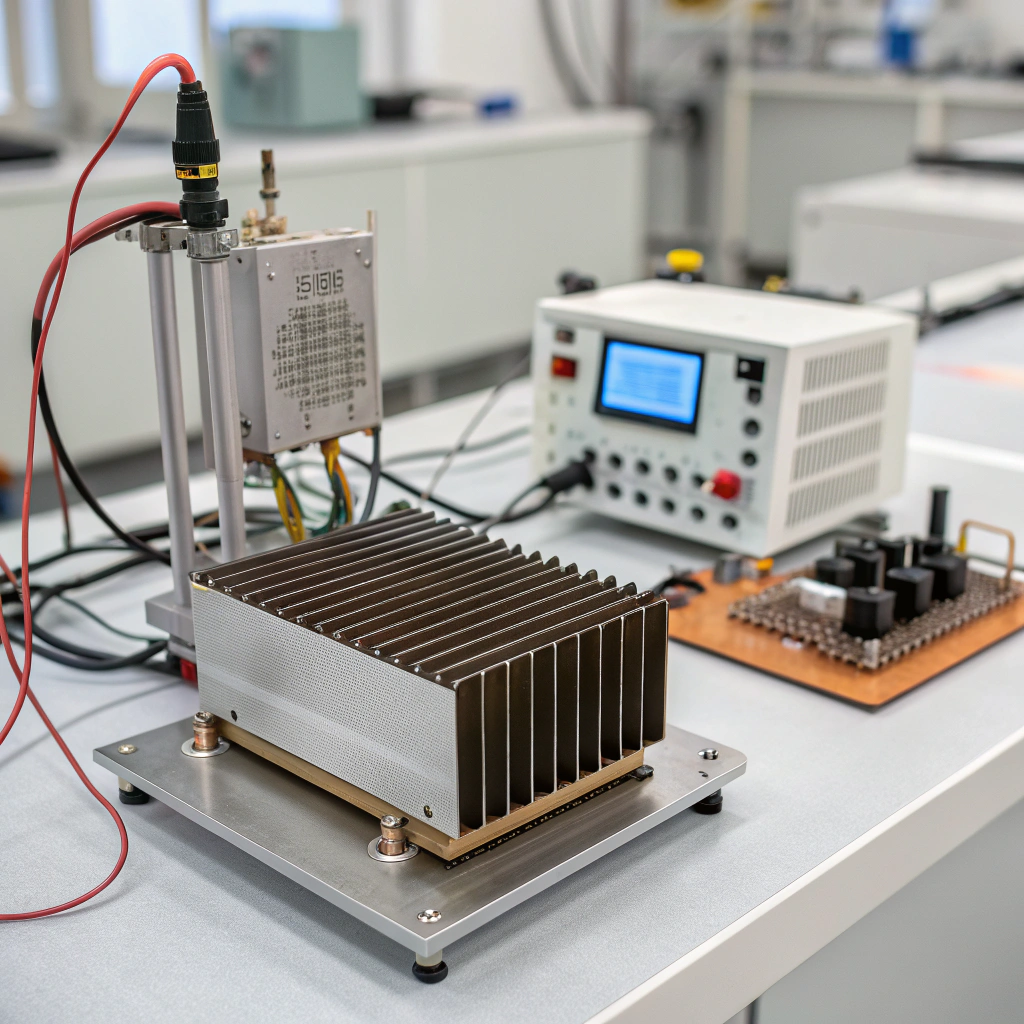

Sometimes people think thermal performance is just a number from a datasheet. But in reality, it’s carefully measured under controlled test conditions.

Thermal performance is tested by applying heat to the base and measuring how fast it dissipates through the fins in a specific environment.

Manufacturers use standardized tests to determine thermal resistance and heat dissipation. Here’s what the typical process looks like:

Standard Test Setup

| Komponente | Beschreibung |

|---|---|

| Heat source | Simulated device (like a power resistor or heater) |

| Baseplate sensor | Measures base temperature |

| Ambient sensor | Measures surrounding air temperature |

| Airflow control | Ensures steady airspeed (e.g., 1 m/s) |

| Data logger | Tracks thermal readings over time |

Test Results Usually Include

- Thermal resistance (°C/W) – lower is better

- Heat dissipation (W) – how much power it can handle

- Temperature delta (ΔT) – difference between base and ambient

When I first started sourcing heat sinks, I misunderstood a spec that said “thermal resistance = 2.5 °C/W.” I thought it was bad. But for a passive aluminum sink with no fan, that was actually good in its category.

Thermal performance of a heat sink is tested by applying heat and measuring temperature differences across the unit.Wahr

This helps quantify how efficiently the heat sink can dissipate heat.

Thermal performance can be judged just by looking at the heat sink's size.Falsch

Testing under controlled conditions is required to determine actual thermal efficiency.

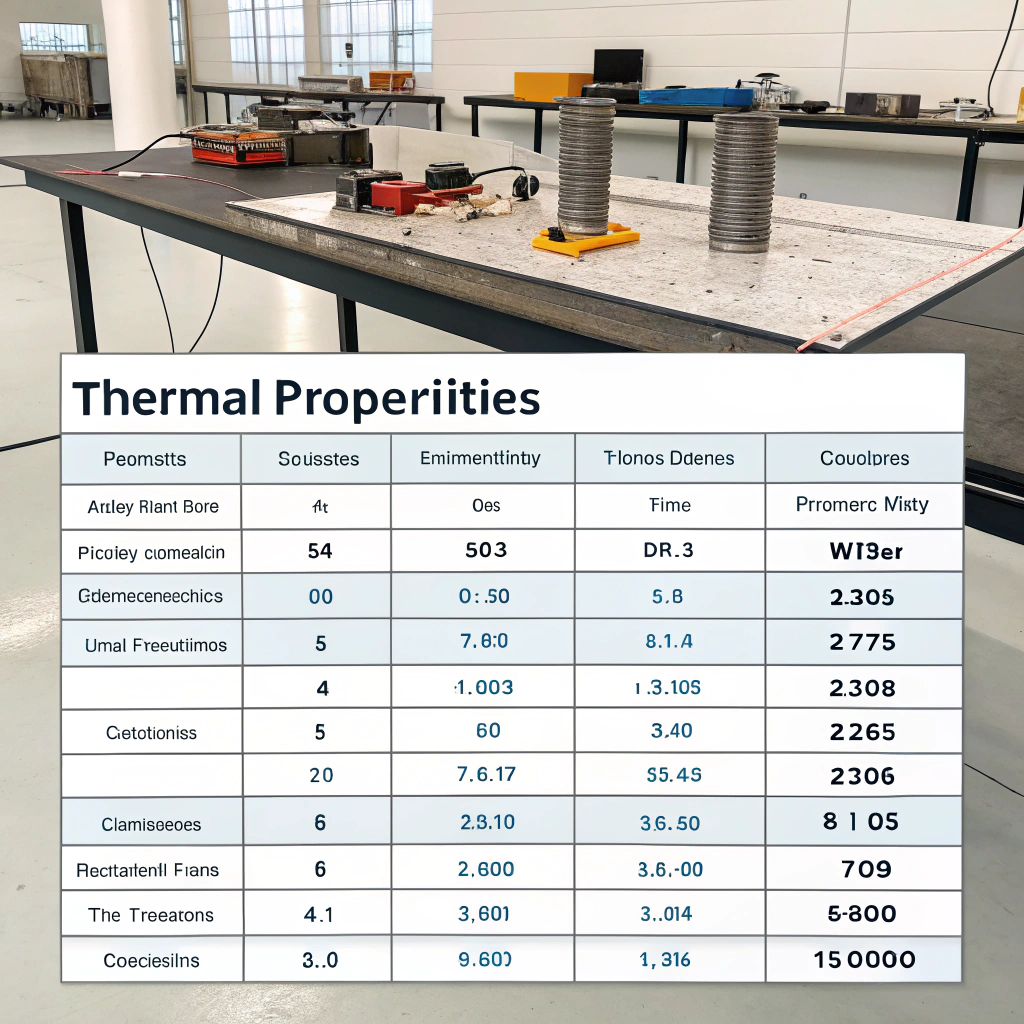

What factors affect thermal conductivity in heat sinks?

It’s easy to think all aluminum heat sinks perform the same. But that’s not true. Several physical and design factors impact how well heat travels through the material.

The alloy type, microstructure, surface finish, and any impurities or treatments can all affect the thermal conductivity of a heat sink.

Let’s break this down into clear categories:

Material Properties That Affect Conductivity

| Faktor | Influence | Anmerkungen |

|---|---|---|

| Legierungstyp | Major | Pure aluminum (99%) > 6063 > 6061 |

| Grain structure | Mäßig | Finer grain improves flow |

| Impurities | Major | Oxides and residues reduce conductivity |

| Temperatur | Minor | Conductivity slightly drops at higher temps |

Design and Processing Factors

| Faktor | Wirkung |

|---|---|

| Qualität der Extrusion | Poor extrusion leads to micro-voids |

| Surface oxidation | Slightly reduces contact heat transfer |

| Machining quality | Rough edges or thermal gaps can create resistance |

I once compared two heat sinks made from different aluminum alloys. One had a conductivity of 230 W/m·K, the other only 170. The lower one had more recycled content and impurities, which affected its cooling capacity significantly under load.

Impurities and alloy type both affect the thermal conductivity of aluminum heat sinks.Wahr

They change the internal structure, which affects how heat moves through the metal.

All aluminum heat sinks have the same thermal conductivity regardless of alloy or manufacturing.Falsch

Different alloys and processes result in different thermal performance.

Is higher W/m·K always better for aluminum heat sinks?

Buyers often chase the highest W/m·K number, thinking it guarantees better performance. But it’s not that simple in real-world applications.

Higher W/m·K means faster heat transfer, but it doesn’t guarantee better cooling without proper design, airflow, and contact quality.

Let’s compare two hypothetical heat sinks:

Vergleichstabelle

| Modell | Wärmeleitfähigkeit (W/m-K) | Thermal Resistance (°C/W) | Airflow Setup |

|---|---|---|---|

| A | 230 | 2.0 | Forced airflow |

| B | 170 | 1.5 | Optimized fin spacing |

In real tests, Model B performed better—even with lower conductivity—because its design helped with airflow and surface area contact.

Other Key Factors Besides W/m·K

- Base-to-fin contact quality

- Surface area (fin density)

- Airflow direction and volume

- Mounting pressure and thermal paste

One customer of ours upgraded to a more conductive heat sink but saw worse results. Turned out their new part had fewer fins and didn’t align with their airflow ducts. Higher W/m·K didn’t help.

Higher W/m·K can improve heat transfer but does not guarantee better overall cooling performance.Wahr

Design and environmental factors play a big role in effectiveness.

The heat sink with the highest W/m·K always cools the best.Falsch

Without good design or airflow, high conductivity may not help.

Do surface treatments impact thermal conductivity values?

You might love the look of anodized or coated heat sinks. But do those finishes affect performance? The answer is both yes and no.

Surface treatments like anodizing can slightly reduce thermal conductivity at the surface but may improve radiation heat transfer.

How Finishes Affect Heat Flow

| Behandlung | Effect on Conductivity | Other Impacts |

|---|---|---|

| Eloxieren | Slightly reduces surface conductivity | Improves corrosion resistance, emissivity |

| Pulverbeschichtung | Insulates surface | Used for cosmetic or protection purposes |

| Clear oxide layer | Minimal impact | Naturally forms on aluminum |

Why Some Treated Sinks Perform Better

Anodized black finishes can improve heat radiation, especially in passive or low-airflow environments. This helps offset the small drop in conductivity.

I’ve had customers request non-anodized sinks thinking they’d be more efficient. But in many outdoor uses, the uncoated aluminum degraded faster due to corrosion, leading to poor long-term performance.

Anodizing can slightly lower thermal conductivity but may enhance radiative cooling in some applications.Wahr

Surface finishes trade off conductivity for corrosion resistance and better emissivity.

All surface treatments improve thermal conductivity of heat sinks.Falsch

Some coatings can reduce heat flow, especially thicker insulative layers.

Schlussfolgerung

Thermal conductivity is a helpful number—but not the only one that matters. A well-designed, properly installed heat sink with average conductivity can outperform a poorly integrated high-conductivity one. Look at the full system, not just the spec sheet.