Welches sind die besten Materialien für Kühlkörper?

Many engineers face confusion when choosing the right heat sink material. Wrong choices lead to overheating, wasted energy, and higher costs.

The best heat sink materials include aluminum, copper, graphite, and advanced composites. Each has unique thermal conductivity, weight, and cost profiles that affect performance.

When I first worked with thermal management parts, I was surprised how material selection changes both cost and efficiency. Let me walk you through each option step by step.

What are the main materials used for heat sinks?

Too many choices often leave designers confused. Picking the wrong material can cause performance or budget problems.

The main heat sink materials are aluminum, copper, graphite, and composites, with aluminum being the most common due to its balance of weight, conductivity, and cost.

Breaking down the materials

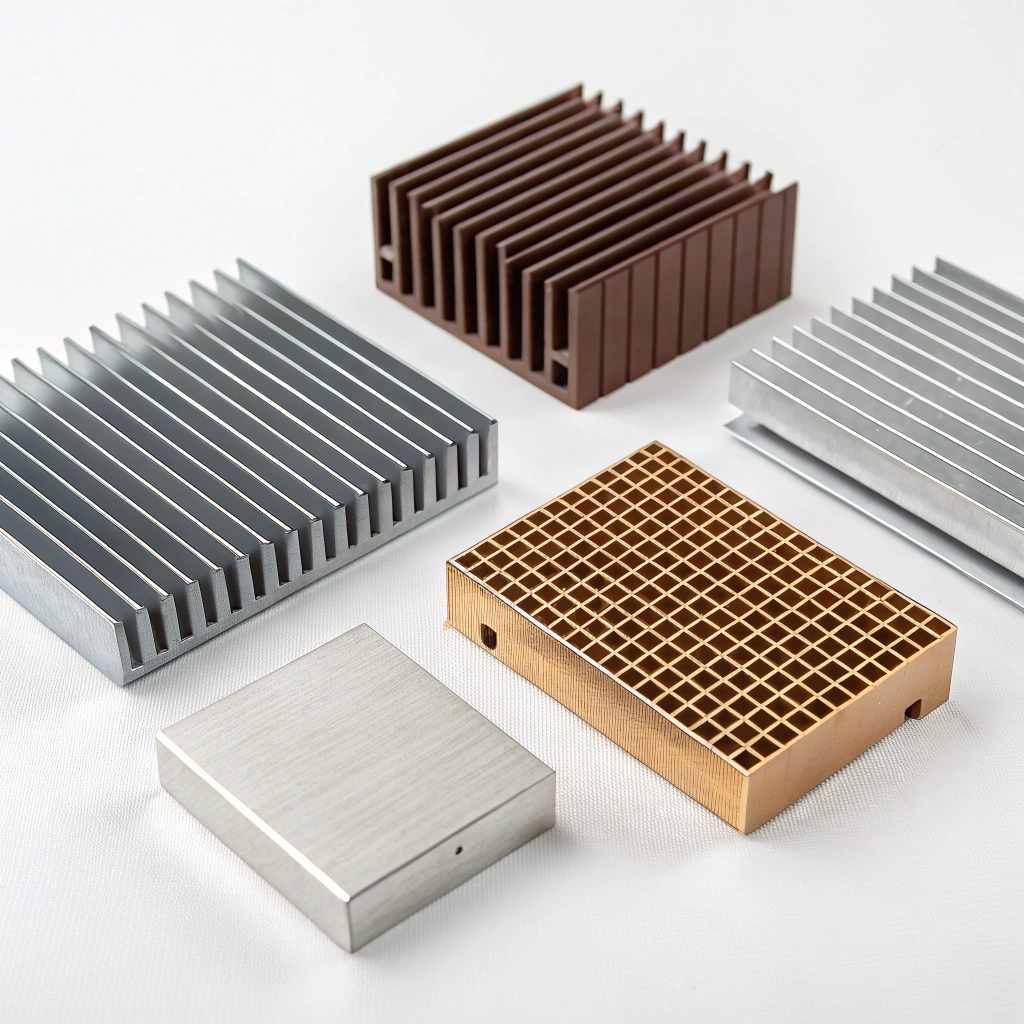

When we talk about heat sinks, four main groups come up:

- Aluminium – lightweight, affordable, easy to shape.

- Kupfer – high conductivity but heavy and expensive.

- Graphit – very light, anisotropic heat spreading.

- Verbundwerkstoffe – mix properties of different materials.

Here is a simple comparison:

| Material | Wärmeleitfähigkeit (W/m-K) | Dichte (g/cm³) | Kostenniveau |

|---|---|---|---|

| Aluminium | ~200 | 2.7 | Niedrig |

| Kupfer | ~400 | 8.9 | Hoch |

| Graphit | 150–500 (anisotropic) | 2.2 | Mittel |

| Verbundwerkstoffe | Variiert | Variiert | Mittel-Hoch |

Aluminum dominates the market because it is easy to extrude and machine. Copper is chosen when maximum heat transfer is required, especially in small areas. Graphite is emerging in electronics for weight-sensitive designs. Composites are still niche but promising.

Aluminum is the most widely used material for heat sinks due to its balance of cost and performance.Wahr

Aluminum offers good thermal conductivity, low weight, and low cost, making it the industry standard.

Copper is lighter than aluminum and usually cheaper.Falsch

Copper is heavier and more expensive than aluminum, despite better conductivity.

How does aluminum compare to copper in heat dissipation?

Many people think copper always performs better. That is only partly true.

Copper has higher thermal conductivity than aluminum, but aluminum often outperforms in real applications due to lighter weight and easier manufacturing.

Looking deeper at performance

Aluminum conducts heat at about half the rate of copper. On paper, copper looks superior. But in practice, several factors change the result. Aluminum is much lighter, so bigger fins can be designed without structural problems. Its lower density also allows for larger surface areas at the same weight.

Manufacturing matters too. Aluminum is easy to extrude into complex shapes. Copper is harder to machine, raising costs. In industries where cost and weight matter—like consumer electronics—aluminum often wins. Copper is used in high-performance CPUs and GPUs where space is tight, and thermal density is high.

| Merkmal | Aluminium | Kupfer |

|---|---|---|

| Leitfähigkeit | ~200 W/m·K | ~400 W/m·K |

| Gewicht | Light (2.7 g/cm³) | Heavy (8.9 g/cm³) |

| Bearbeitbarkeit | Easy to extrude | Harder to process |

| Kosten | Niedrig | Hoch |

Aluminum heat sinks are usually lighter and cheaper than copper heat sinks.Wahr

Aluminum has lower density and lower raw material cost, making it easier to use for large designs.

Copper heat sinks are always the better choice in every application.Falsch

Copper provides higher conductivity, but weight, cost, and manufacturability often make aluminum preferable.

Is graphite better than metal for heat sinks?

Some engineers get excited about graphite and think it is always superior. But reality is more complex.

Graphite can outperform metals in specific cases due to lightweight and anisotropic conductivity, but it is not universally better than aluminum or copper.

The graphite factor

Graphite has a unique property: its thermal conductivity is very high in-plane but much lower through-plane. That means it spreads heat across a surface well but does not conduct heat vertically as efficiently. This makes it ideal for thin devices like smartphones, where spreading heat across the backplate is more important than vertical dissipation.

Graphite is also much lighter than copper or aluminum. This helps in aerospace or portable electronics. However, it is more brittle, harder to machine, and not suitable for large extruded shapes. Its cost is also higher compared to mass-produced aluminum extrusions.

In summary, graphite is excellent for spreading heat in small, thin applications. For bulk dissipation, metals like aluminum or copper still lead.

Graphite spreads heat very effectively across surfaces due to anisotropic conductivity.Wahr

Graphite’s in-plane conductivity is much higher than through-plane, making it useful in thin devices.

Graphite is always stronger and easier to machine than aluminum.Falsch

Graphite is brittle and hard to machine compared to ductile aluminum.

Which heat sink material offers best cost-performance ratio?

Decision-makers often worry about budget. Many assume copper is worth the extra money. But the numbers tell a different story.

Aluminum offers the best cost-performance ratio among heat sink materials, balancing conductivity, weight, manufacturability, and price.

Cost versus performance analysis

Let’s compare value. Aluminum is affordable, lightweight, and provides good thermal conductivity. Copper doubles the conductivity but comes at triple the weight and higher cost. Graphite offers unique spreading but is expensive and application-specific. Composites show promise but remain costly.

For mass-market products like LED lighting, automotive parts, and computers, aluminum gives the best mix. Copper is chosen only for niche, high-power density needs. Graphite and composites fill special roles, but they cannot replace aluminum in most cases.

Here is a simplified ranking:

| Material | Leitfähigkeit | Kosten | Manufacturability | Overall Value |

|---|---|---|---|---|

| Aluminium | Gut | Niedrig | Einfach | Ausgezeichnet |

| Kupfer | Ausgezeichnet | Hoch | Hart | Mittel |

| Graphit | Variabel | Mittel | Mäßig | Niche |

| Verbundwerkstoffe | Variabel | Hoch | Komplexe | Begrenzt |

Aluminum provides the best balance of cost and thermal performance.Wahr

It is affordable, easy to machine, lightweight, and widely available.

Copper offers the best cost-performance ratio for most consumer products.Falsch

Copper is too expensive and heavy for most consumer applications compared to aluminum.

What are the drawbacks of using copper in heat sinks?

Some people only look at copper’s high conductivity and forget about trade-offs.

Copper heat sinks are heavy, expensive, harder to manufacture, and prone to oxidation, despite superior thermal conductivity.

The downside of copper

Copper conducts heat twice as well as aluminum, but its disadvantages limit use. Its density makes it heavy, which is unsuitable for aerospace or handheld electronics. Its cost is much higher, which drives up total product price. Processing copper is more difficult because it is less ductile than aluminum for extrusion.

Oxidation is another problem. Over time, copper tarnishes, which can reduce performance and require protective coatings. In contrast, aluminum naturally forms a protective oxide layer that resists corrosion.

So, copper is excellent for compact high-performance systems like CPUs, but aluminum is preferred for most commercial uses.

Copper heat sinks are heavier and more expensive than aluminum ones.Wahr

Copper has higher density and cost, which makes it less suitable for many applications.

Copper naturally resists oxidation better than aluminum.Falsch

Aluminum forms a protective oxide layer, while copper tarnishes and can degrade without coatings.

Schlussfolgerung

Heat sink material choice depends on balance. Aluminum gives the best value, copper gives peak performance at higher cost, graphite fits thin devices, and composites remain niche. Picking the right one depends on application, not just conductivity.

![[Product Name] - [Key Features or Description] Image of [Product Name] featuring [Key Features or Description]](https://sinoextrud.com/wp-content/uploads/image-of-product-name-featuring-key-features-or-description.webp)