CNC-Bearbeitung Guyana: Hersteller & Industrieführer

Teil 1: Marktgröße und Wachstum

Guyana is moving from a small industrial base to a fast-growing, energy-driven economy. Oil discoveries offshore, plus mining, construction, and agriculture, are changing demand for precision parts. CNC machining fits this shift because it supports uptime, safety, and predictable quality. I see local workshops trying to move beyond manual tools and into digital workflows.

I track three forces behind the growth. First, oil and gas suppliers need tight-tolerance parts for rigs, vessels, and onshore facilities. Second, construction and infrastructure projects need fixtures, jigs, and replacement components. Third, mining, rice, and forestry need durable spares to cut downtime in remote areas. These needs reward shops that can prototype fast and hit repeatable tolerances.

Policy and investment also matter. Guyana’s membership in CARICOM eases regional sourcing and sales. New industrial zones near Georgetown can host light fabrication, testing, and storage. If technical colleges expand CNC curricula, the labor pool will grow. I still remember a tour of a small bay in Georgetown where a machinist told me, “I learned on a manual lathe, but I dream in G-code now.” This mindset will push the market forward.

Teil 2: Führende Unternehmen

Georgetown Precision Machining

Jetzt kontaktieren

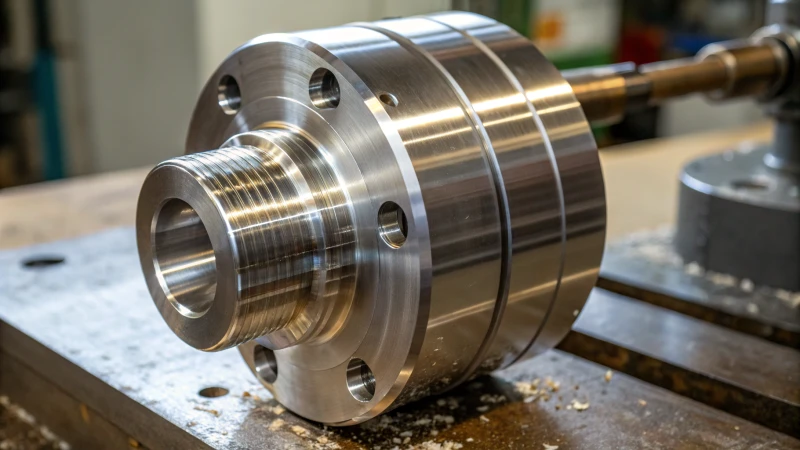

Georgetown Precision Machining is a local shop concept I use to describe the new wave of fabrication in the capital. It focuses on CNC milling, turning, and small-run prototyping for oil and gas contractors, marine service firms, and construction integrators. The team started with conventional lathes and then layered on 3-axis machining to improve cycle times.

The shop offers fixture design, reverse engineering, and quick repairs for pumps, valves, and gear housings. It accepts STEP and DXF files and runs simple CAM to shorten programming time. I watched a technician align a soft jaw set and dial in concentricity before a rush job for a dock client. That discipline is how small shops win repeat orders.

Key industries include offshore logistics, port maintenance, and public works. The shop’s innovation is not exotic hardware but process control. It tracks tool wear, records offsets, and builds job travelers for traceability. It aims for ISO 9001 readiness and has completed safety inductions with major operators to meet site access rules.

Essequibo CNC Works

Jetzt kontaktieren

Essequibo CNC Works represents the rise of regional capacity along the Essequibo Coast and river communities. The workshop blends CNC routers for plastics and wood with mills and lathes for metals. This hybrid setup fits Guyana’s mixed economy, serving agriculture, forestry, and light marine.

Products include custom sprockets, bushings, wear plates, pump brackets, seed processing spares, and boat hardware. The team often receives worn parts with no drawings. They digitize key surfaces, model replacements, and cut new components within days. I once saw a similar workflow in a rural repair shed; it saved a farmer’s harvest window by avoiding import delays.

The shop focuses on training. Operators learn toolpath basics, feeds and speeds for hardwoods and 6061, and safe workholding on thin stock. Small design choices, like fillet radii and slot widths, prevent chatter and rework. The firm plans to partner with TVET programs to build a talent pipeline.

Demerara Tool & Fabrication

Jetzt kontaktieren

Demerara Tool & Fabrication is a heavy-duty player that supports mining, bridges, and port cranes. It runs CNC turning for shafts and bushings, plus horizontal milling for large plates. The team still uses manual machines for oversized jobs, but it brings CNC where tolerance or repeatability matter most.

The service mix includes hard-facing, line boring, and jig fabrication to speed site installs. Customers send assemblies to the shop’s yard for inspection and disassembly. The crew documents each part, creates routings, and machines replacements with clear QC steps. The value is less about shiny machines and more about predictable outcomes.

The company invests in metrology: calibrated micrometers, bore gauges, height stands, and a simple CMM service via a partner. It chases certifications tied to safety and lifting operations. As bridge and road projects scale, the shop plans palletized workholding to cut setup time on repeat jobs.

Unternehmensvergleichstabelle

| Unternehmen | Founded / Location | Kernprodukte | Branchen | Zertifizierungen |

|---|---|---|---|---|

| Georgetown Precision Machining | Georgetown | CNC milling & turning, prototyping, reverse engineering | Oil & gas, marine, construction | ISO 9001-ready (target) |

| Essequibo CNC Works | Essequibo Coast | Hybrid CNC (router + mills/lathes), spares, fixtures | Agriculture, forestry, boat repair | In progress |

| Demerara Tool & Fabrication | Demerara | Heavy turning, plate milling, line boring | Mining, infrastructure, ports | Safety & lifting inductions |

Teil 3: Fachmessen und Branchenveranstaltungen

Guyana Manufacturing & Services Association Expo (GMSA Expo)

This national event brings manufacturers, fabricators, importers, and service firms together in Georgetown. I like it because small CNC shops can meet buyers from construction, food processing, and energy, and also see tools from regional distributors. The floor often mixes machinery booths with packaging, logistics, and engineering services.

Typical timing is annual, with pavilions for local producers and international partners. Exhibitor lists include industrial suppliers, safety gear vendors, and machine tool agents. Highlights for CNC users are toolholding demos, cutting fluid trials, and live metrology tutorials. I once joined a short talk on fixture design where a speaker showed how soft jaws improved repeatability by 40%.

Guyana International Petroleum Exhibition (GIPEX)

GIPEX focuses on oil and gas supply chains, but CNC shops benefit from attending. Vessel maintenance, topside equipment, and onshore support bases all consume machined parts. A booth or a visitor badge can open doors to procurement teams and technical managers who buy spares all year.

The show usually features operator briefings, HSE sessions, and supplier development programs. For machining, key highlights include flange and valve repair case studies, NDT workflows, and vendor qualification checklists. I advise shops to carry sample parts, surface finish charts, and a one-page capability matrix.

| Veranstaltung | Datum | Standort | Höhepunkte |

|---|---|---|---|

| GMSA Expo | Jährlich | Georgetown | Tooling demos, metrology tips, sourcing partners |

| GIPEX | Jährlich | Georgetown | Oil & gas supply chain, vendor qualification, HSE focus |

Teil 4: Auswirkungen globaler Handelspolitiken

Global trade rules shape everything from machine prices to tool lead times. Guyana’s open economy and CARICOM ties help with regional sourcing. However, currency swings and shipping constraints can still slow deliveries. I have waited weeks for a simple carbide order when a vessel was delayed, and that memory still informs my planning.

Sanctions and export controls can affect advanced controllers, precision bearings, and electronics. Tariff changes may hit steel, aluminum, and specialty alloys. Shops need playbooks: second-source tools, standardize material grades, and maintain minimum safety stock of inserts and coolants. Where possible, partner with regional distributors in Trinidad, Barbados, or Suriname to buffer supply shocks.

Local substitution is not a buzzword; it is survival. A shop that can refurbish spindles, rebuild valves, and re-grind cutters protects customers from import delays. Nearshoring trends also help because regional OEMs may place small runs closer to operations. The risk is quality drift if training lags. That is why documented procedures, gauge R&R, and simple SPC charts matter as much as the new machine itself.

Teil 5: Schlussfolgerung

Guyana’s CNC story is about timing. Demand is rising across oil and gas, public works, mining, and agriculture. Entrepreneurs are upgrading from manual ways to controlled, data-driven machining. Shops that pair reliable process with fast response will win. I felt that energy on a quay in Georgetown as a foreman described his “midnight mill” job that kept a vessel on schedule.

Risks are real: skills shortages, import delays, power quality, and certification costs. Still, the path is clear. Invest in people, measure what matters, and keep records clean. If we do that, CNC machining in Guyana can move from repair mode to a true precision ecosystem, serving domestic needs and the wider Caribbean in the years ahead.

Empfohlene Lektüre:

- CNC Machining Seychelles: Manufacturers & Industry Guide

- CNC-Bearbeitung Botswana: Hersteller & Industrieführer

Was ist die maximale Größe von Aluminium-Strangpressprofilen?

60 Serie T-Nut Aluminium Strangpressprofil

Aluminium-Kühlkörper für die Kühlung elektronischer Bauteile

Aluminium Strangpressen Galvanisiertes Duschraum Aluminium Profil