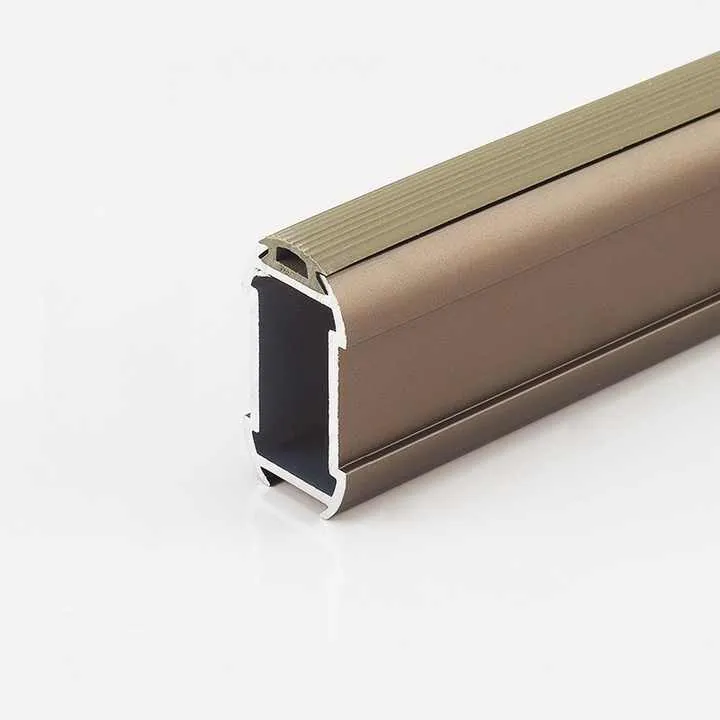

Aluminum extrusion coating adhesion requirements?

Coatings fail more often from poor adhesion than from poor material choice. Peeling, blistering, and flaking usually appear after installation. Many buyers focus on coating thickness and color. Adhesion is checked too late.

Aluminum extrusion coating adhesion depends on surface condition, preparation method, coating type, and test standards used to verify bond strength.

In real projects, adhesion problems lead to rework, delays, and customer complaints. This article explains which adhesion standards apply, how adhesion is tested, why pre-cleaning matters, and which coatings bond best to anodized aluminum.

What adhesion standards apply to coatings?

Many coating defects trace back to unclear standards. Without defined adhesion criteria, suppliers and buyers judge quality differently. This causes disputes.

Coating adhesion on aluminum extrusions is commonly defined by cross-hatch, pull-off, or bend test standards specified by ISO and ASTM methods.

Why adhesion standards are required

Adhesion standards give a common language. They define how much force or damage is acceptable before failure. Without standards, inspection becomes subjective.

Standards help:

- Lieferanten vergleichen

- Set pass or fail limits

- Reduce quality disputes

They also guide coating line setup and surface preparation.

Commonly referenced standards

Most industrial aluminum coatings follow a small group of standards.

| Standard | Test Typ | Typische Verwendung |

|---|---|---|

| ASTM D3359 | Cross-hatch | Pulverbeschichtung |

| ISO 2409 | Cross-cut | Anodized or painted |

| ASTM D4541 | Pull-off | High performance coatings |

These standards are widely accepted and easy to audit.

How standards are specified in orders

Good purchase orders do not just say “good adhesion.” They specify:

- Test method

- Acceptance class or rating

- Test location and frequency

For example, cross-hatch class 0 or class 1 is often required for architectural coatings.

Practical issues seen in factories

In practice, adhesion can vary across one profile. Corners, weld seams, and thick sections behave differently.

Because of this, serious buyers:

- Define critical test areas

- Require routine line audits

- Keep records per batch

This approach reduces random failures after delivery.

Coating adhesion is commonly evaluated using ASTM and ISO test standards.Wahr

These standards define accepted methods and ratings for adhesion.

There are no formal standards for coating adhesion on aluminum extrusions.Falsch

Multiple international standards are widely used.

How is adhesion tested on extruded surfaces?

Testing adhesion is not complex. Still, incorrect testing leads to wrong conclusions. Method selection must match coating type and application.

Adhesion on aluminum extrusions is tested by mechanically stressing the coating through cutting, pulling, bending, or impact methods.

Cross-hatch and cross-cut testing

This is the most common method. A grid is cut through the coating to the substrate. Tape is applied and removed.

The result is rated based on how much coating detaches.

Vorteile:

- Schnell

- Geringe Kosten

- Easy to repeat

Limitations:

- Surface damage

- Subjective edge evaluation

Pull-off testing

Pull-off testing measures actual force required to detach a coating. A dolly is glued to the surface and pulled perpendicular.

This method gives numerical values. It is useful for thick or critical coatings.

Allerdings:

- It damages the part

- Surface prep affects glue strength

- Not suitable for thin decorative layers

Bend and deformation tests

Some extrusions are bent or formed after coating. Bend tests check if coating cracks or peels during deformation.

These tests are common in:

- Automobilteile

- Frames with post processing

Choosing the right test

| Prüfverfahren | Am besten für | Not Ideal For |

|---|---|---|

| Cross-hatch | Pulverbeschichtung | Very thick films |

| Pull-off | Heavy duty coatings | Thin decorative finishes |

| Biegetest | Formed profiles | Rigid structures |

Testing should reflect real service conditions.

Cross-hatch testing checks coating adhesion by cutting and tape removal.Wahr

This method evaluates coating bond by observing detachment.

Pull-off tests do not damage the aluminum extrusion.Falsch

They permanently damage the tested area.

Can pre-cleaning improve coating adherence?

Poor adhesion often starts before coating. Surface contamination blocks bonding. Many failures come from skipping or shortening cleaning steps.

Proper pre-cleaning significantly improves coating adhesion by removing oils, oxides, and residues from aluminum extrusion surfaces.

Sources of surface contamination

Extrusions leave the press with residues. Handling adds more.

Common contaminants include:

- Extrusion lubricants

- Cutting oils

- Fingerabdrücke

- Natural oxide layers

Even clean looking surfaces can block adhesion.

Pre-cleaning methods used in industry

Several cleaning stages are common before coating.

Entfettung

Alkaline or solvent degreasing removes oils and organic matter.

Ätzen

Acid or alkaline etching removes surface oxides and creates micro roughness.

Conversion coating

Chromate or chrome free systems improve chemical bonding between aluminum and coating.

Impact of cleaning on adhesion results

In production, proper cleaning often improves cross-hatch results by one or two classes. It also reduces long term delamination.

| Cleaning Level | Typical Adhesion Result |

|---|---|

| Minimal wipe | Poor to fair |

| Degrease only | Messe |

| Full pretreatment | Good to excellent |

This shows why pretreatment investment pays off.

Common mistakes seen in projects

Some buyers request low cost coating and skip pretreatment. Initial appearance looks fine. Failures appear after months.

Zu den bewährten Verfahren gehören:

- Auditing pretreatment lines

- Checking chemical concentration

- Monitoring rinse water quality

These controls protect adhesion consistency.

Surface pre-cleaning improves coating adhesion on aluminum extrusions.Wahr

It removes contaminants and improves bonding.

Coating adhesion is not affected by surface contamination.Falsch

Contamination blocks proper bonding.

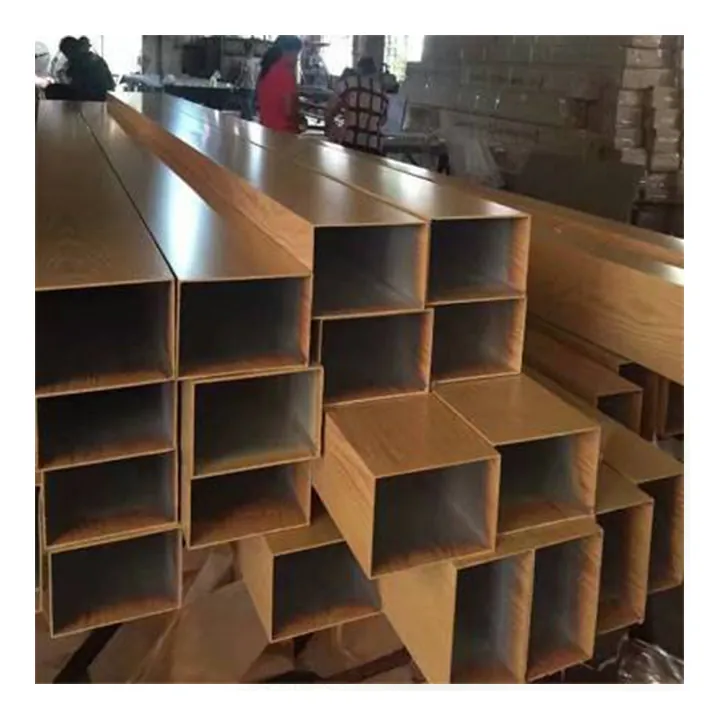

Which coatings adhere best on anodized aluminum?

Anodized aluminum has a stable oxide layer. This layer improves corrosion resistance. It also changes how coatings bond.

Coatings that chemically bond or mechanically key into anodized aluminum pores show the best adhesion performance.

Nature of anodized surfaces

Anodizing creates a porous oxide structure. These pores can accept dyes or sealants. They also affect coating adhesion.

Unsealed anodizing allows better mechanical anchoring. Fully sealed surfaces reduce adhesion.

Coatings commonly applied on anodized aluminum

Not all coatings behave the same.

| Art der Beschichtung | Adhesion on Anodized Surface |

|---|---|

| Pulverbeschichtung | Good with proper prep |

| Epoxidfarbe | Sehr gut |

| Acrylic paint | Mittel |

| Silicone based | Schlecht |

This table helps guide coating selection.

Preparation before coating anodized parts

Light abrasion or chemical activation improves adhesion. Cleaning alone is often not enough.

In real production:

- Light sweep blasting is used

- Chemical activation opens pores

- Over sealing is avoided

Lessons from field applications

Projects fail when anodized parts are coated without review. The oxide layer is assumed to help. In reality, it can reduce bonding if sealed.

Clear communication between anodizing and coating processes is critical. Process compatibility must be verified before mass production.

Porous anodized surfaces can improve mechanical anchoring of coatings.Wahr

Open pores allow better bonding.

All coatings adhere equally well to sealed anodized aluminum.Falsch

Sealing reduces adhesion for many coatings.

Schlussfolgerung

Coating adhesion on aluminum extrusions depends on clear standards, correct testing, proper pre-cleaning, and coating compatibility. Defining adhesion requirements early helps prevent peeling, rework, and long term failure.