Aluminum extrusion thermal expansion rate?

Thermal expansion often hides until it causes cracks, noise, or misalignment. Many buyers only notice it after installation. This topic deserves clear answers before problems appear.

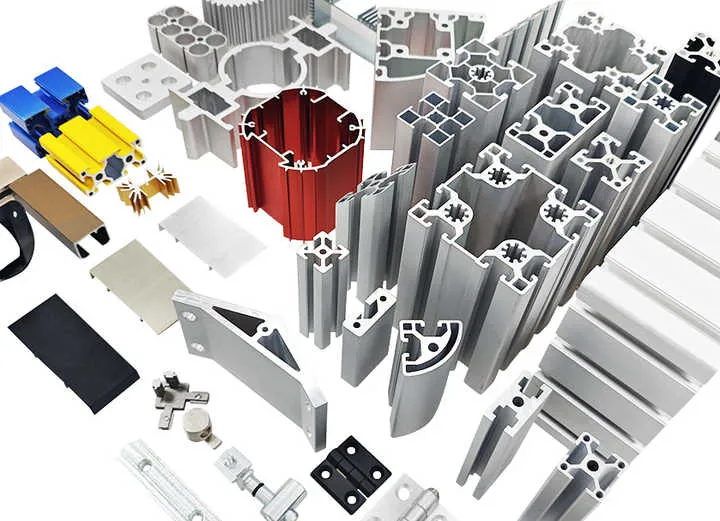

The thermal expansion rate of aluminum extrusions explains how much the profile length changes when temperature changes. Understanding this rate helps prevent deformation, stress, and failure in real projects.

This subject connects material science with real construction and industrial use. Knowing the basics is not enough. What matters is how this behavior shows up in daily production and large structures.

What is the average thermal expansion rate of extrusions?

Thermal movement can damage joints and assemblies if ignored. Many projects fail because designers assume metal stays stable. Aluminum does not behave this way.

The average thermal expansion rate of aluminum extrusions is about 23 x 10^-6 per degree Celsius. This means one meter of aluminum grows about 0.023 mm for every 1 C increase in temperature.

This value sounds small, but the effect becomes large over long lengths and wide temperature ranges. In extrusion projects, profiles often reach several meters. Outdoor use may face a temperature swing of more than 50 C. That creates visible and measurable movement.

Why aluminum expands more than steel

Aluminum atoms move more when heated. The crystal structure allows more spacing change compared to steel. This is why aluminum feels more reactive to heat even though it cools fast.

In practice, this property brings both benefits and risks. Aluminum resists cracking under thermal shock. But it needs space to move.

Typical expansion values in real projects

Below is a simple table used during early design stages. It helps buyers estimate movement before final drawings.

| Length of extrusion | Temperature change | Total expansion |

|---|---|---|

| 1 meter | 30 C | 0.69 mm |

| 3 meters | 40 C | 2.76 mm |

| 6 meters | 50 C | 6.90 mm |

These numbers are averages. Surface finish, alloy, and stress state may change the result slightly. Still, this table prevents common mistakes.

Why average values are only a starting point

Average rates do not replace engineering checks. They help early decisions. Final designs need allowance slots, sliding joints, or flexible connectors.

In extrusion factories, this rate also affects cutting tolerance. Profiles cut at high temperature may shrink after cooling. Good workshops plan for this during production.

Aluminum extrusions expand noticeably with temperature changes, especially in long profiles.True

The expansion rate of aluminum causes measurable length changes when temperature varies, and this effect grows with profile length.

Thermal expansion of aluminum extrusions can usually be ignored in outdoor structures.False

Outdoor structures often face large temperature ranges, making expansion a critical design factor.

How does alloy composition influence expansion rate?

Many buyers assume all aluminum behaves the same. This is not true. Alloy choice changes thermal behavior in small but important ways.

Alloy composition slightly changes the thermal expansion rate, but the difference is usually within a narrow range for common extrusion alloys like 6063 and 6061.

The base metal is aluminum. Alloying elements adjust strength, hardness, and corrosion resistance. They also influence atomic spacing.

Comparing common extrusion alloys

6063 and 6061 are widely used. Both belong to the aluminum magnesium silicon family. Their expansion rates are close, but not identical.

| Alloy | Typical expansion rate (per C) | Common use |

|---|---|---|

| 6063 | ~23.5 x 10^-6 | Architectural profiles |

| 6061 | ~23.1 x 10^-6 | Structural and industrial |

The difference looks small on paper. In a 10 meter structure with large heat swings, even this gap matters when tolerances are tight.

Role of temper and heat treatment

Temper like T5 or T6 changes internal stress. It does not greatly change expansion rate, but it affects how stress builds during movement.

A profile in T6 condition resists deformation better. But if expansion is blocked, internal stress becomes higher. This may cause bending or joint failure.

Why alloy choice still matters for expansion control

Even if expansion rate differences are small, alloy choice links to other factors. Strength allows longer spans. Surface treatment affects heat absorption. Dark anodized profiles heat faster under sun.

Designers should not isolate expansion from other material choices. All decisions interact.

Different aluminum extrusion alloys have identical thermal expansion behavior.False

While similar, common alloys like 6063 and 6061 have slightly different expansion rates that can matter in precise designs.

Alloy selection affects not only strength but also how thermal expansion stress is managed.True

Alloy properties influence how expansion stress builds and how the profile responds under constraint.

Can expansion be controlled in large structures?

Large aluminum structures often fail not from load, but from restrained movement. Expansion control is not about stopping movement. It is about guiding it.

Thermal expansion cannot be eliminated, but it can be controlled using design features like expansion joints, sliding connections, and proper spacing.

This principle applies to curtain walls, solar frames, transport systems, and industrial lines.

Design methods used in large extrusion systems

The most common solution is allowance. Profiles are fixed at one point and allowed to slide at others. This prevents stress buildup.

Common methods include:

- Slotted holes instead of round holes

- Floating brackets

- Rubber or polymer spacers

- Telescopic profile design

Example from industrial frames

In long conveyor frames, aluminum extrusions may run over 20 meters. The frame is anchored at the center. Both ends are free to move. This balances expansion in both directions.

Ignoring this method leads to bowing or noise during daily temperature cycles.

Surface treatment and thermal behavior

Surface finish changes how fast heat enters the profile. Dark coatings absorb more heat. Bright finishes reflect more sunlight.

This does not change expansion rate. It changes temperature range. A higher temperature swing means more movement.

Installation quality matters as much as design

Even a good design fails if installers overtighten bolts. Bolts should allow movement where planned. Torque control and clear instruction are critical.

In export projects, installation conditions vary by country. Clear drawings reduce risk.

Thermal expansion in aluminum structures must be allowed rather than fully restrained.True

Allowing controlled movement prevents stress, deformation, and failure in large aluminum extrusion systems.

Using thicker aluminum profiles eliminates the need for expansion allowances.False

Profile thickness does not stop thermal expansion; it only changes stiffness, not movement.

Which tests verify expansion behavior under heat?

Thermal behavior should not rely only on theory. Testing confirms assumptions before mass production or installation.

Thermal expansion behavior is verified using laboratory tests such as dilatometer testing, thermal cycling tests, and controlled heating measurements.

These tests provide data for engineers and buyers.

Dilatometer testing explained simply

A dilatometer measures length change under controlled heating. A small sample is heated at a steady rate. Sensors track expansion.

This test gives precise expansion coefficients. It is used in material development and quality checks.

Thermal cycling tests for real conditions

Thermal cycling exposes full profiles to repeated heating and cooling. This simulates day and night cycles.

Engineers observe:

- Permanent deformation

- Joint loosening

- Surface cracking

- Noise from movement

This test is useful for curtain walls and outdoor frames.

Production level checks

In extrusion plants, indirect checks are more common. These include:

- Dimensional checks at different temperatures

- Straightness checks after cooling

- Assembly trials in hot conditions

These steps ensure profiles behave as expected when shipped.

When buyers should request test data

Not every project needs lab reports. High risk cases do. These include:

- Very long profiles

- Tight tolerance assemblies

- Extreme climate regions

Clear communication avoids disputes later.

Laboratory testing can accurately measure the thermal expansion coefficient of aluminum extrusions.True

Dilatometer and controlled heating tests provide precise data on expansion behavior.

Thermal expansion testing is unnecessary once an alloy grade is selected.False

Even with known alloys, testing helps confirm behavior in specific profile designs and applications.

Conclusion

Thermal expansion is a predictable behavior, not a defect. Aluminum extrusions perform well when movement is planned and guided. Clear design, correct alloy choice, and proper testing prevent most expansion related failures.