What size is 4040 aluminum extrusion

Many customers get confused when they see part numbers like 4040 or 5050. They all look similar — so what exactly do these numbers mean?

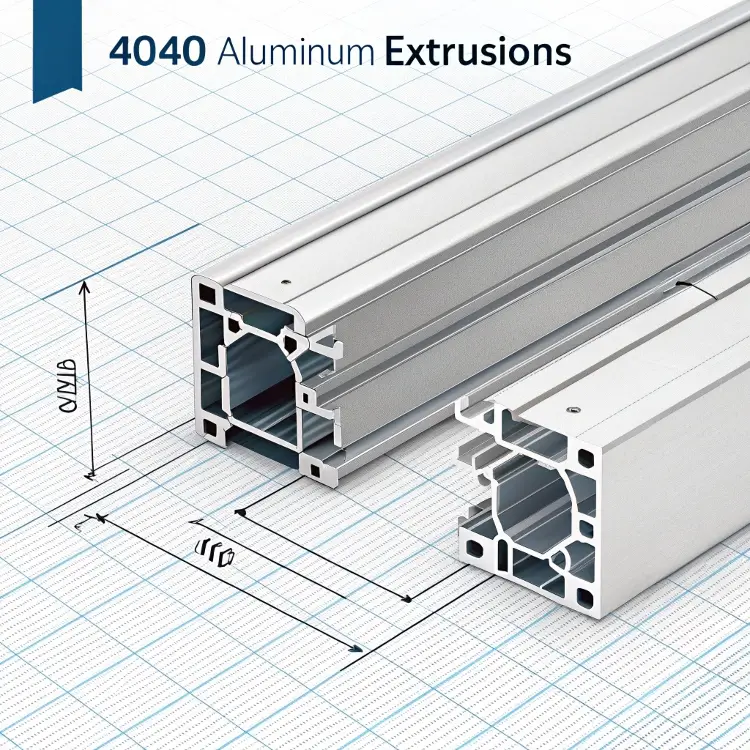

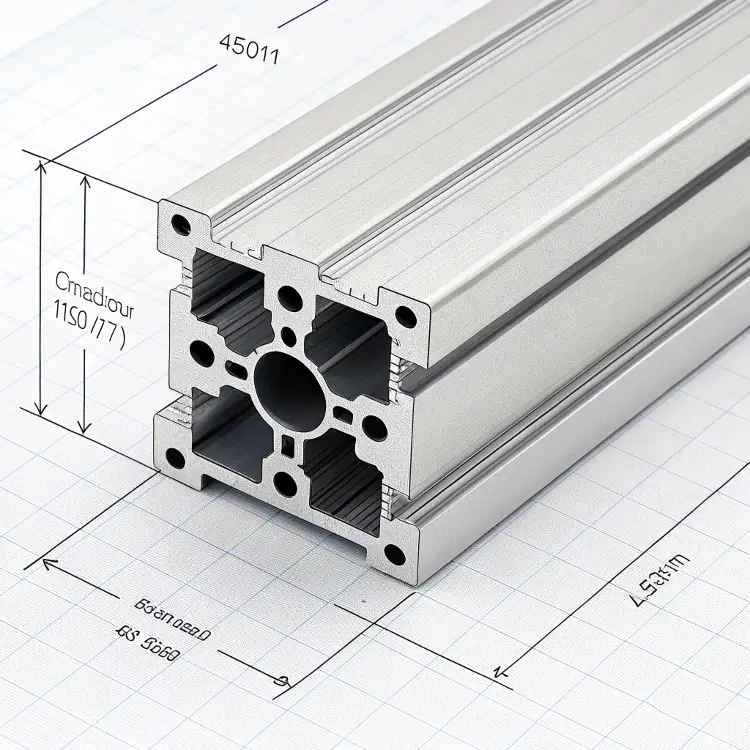

4040 aluminum extrusion refers to a T-slot profile that is 40mm x 40mm in cross-sectional dimensions, typically with slots on each face for mounting and modular assembly.

If you’ve ever been puzzled by these four-digit codes like 4040 or 8020, you’re not alone. These numbers actually describe a lot about the aluminum profile’s size and application. Let me walk you through it.

What are the dimensions of 4040 aluminum extrusion?

Many engineers and purchasing managers make assumptions about 4040 just by the name — but do you know exactly what you’re getting?

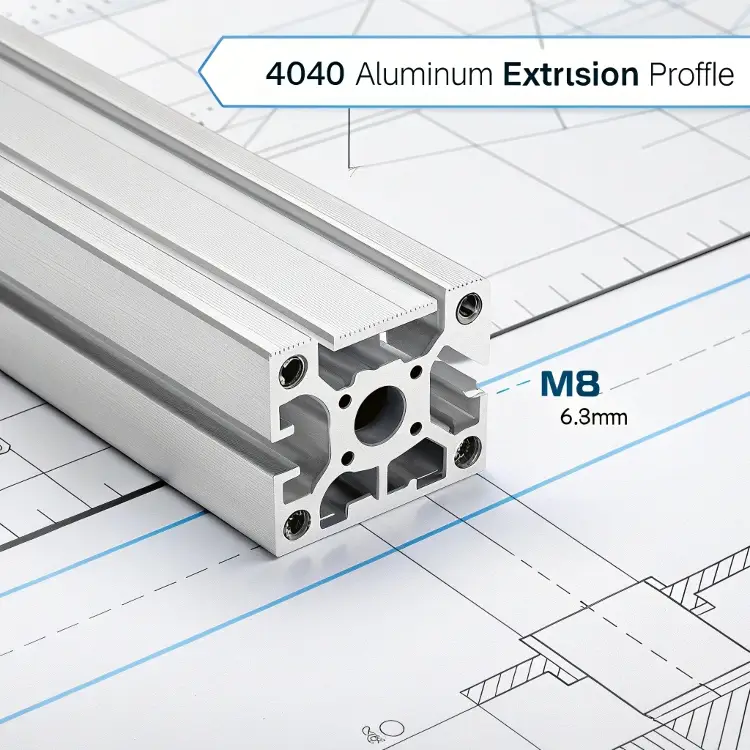

The dimensions of 4040 aluminum extrusion1 are 40mm by 40mm, with slots typically 8mm wide. The standard center bore is often M8 or ?6.8mm.

4040 aluminum extrusion follows the metric T-slot standard2, where the first two digits (40) indicate the profile width in millimeters, and the second two digits (40) indicate the height. These extrusions are generally square, making them ideal for building frames, machine enclosures, and modular workstations.

Detailed Specs of 4040 Aluminum Extrusion

| Specification | Detail |

|---|---|

| Profile Size | 40mm x 40mm |

| Slot Width | 8mm |

| Slot Depth | \~6.8mm |

| Center Bore | ?6.8mm or M8 |

| Material | 6063-T5 or 6061-T6 |

| Surface Treatment | Anodized, Powder Coated |

Different manufacturers may vary slightly in tolerance and surface finish. At Sinoextrud, we guarantee ISO-standardized profiles with precision cutting and quality control.

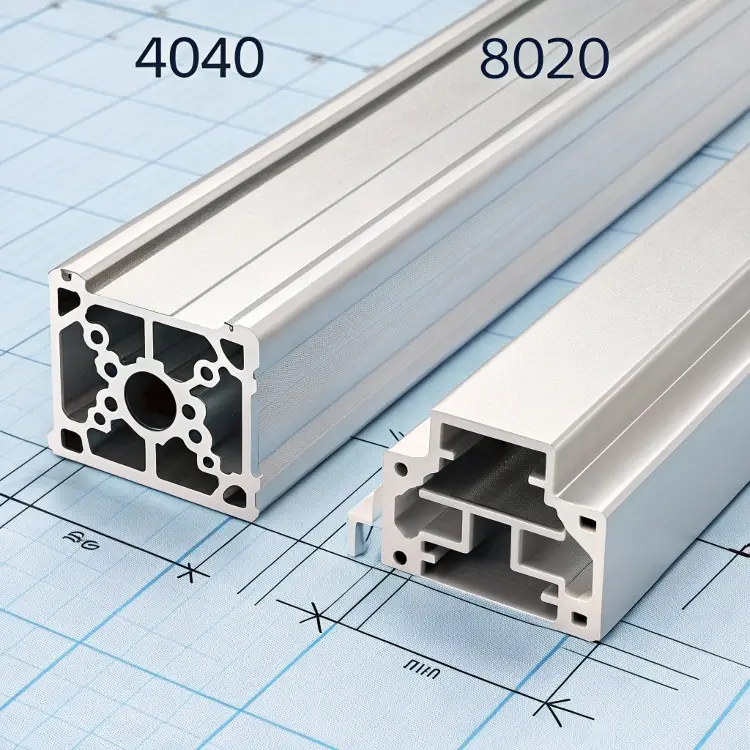

What is the difference between 4040 and 8020?

Both profiles look similar and serve similar functions — so why are the numbers so different?

4040 is 40mm x 40mm, and 8020 is 80mm x 20mm; the numbers reflect the dimensions and shape. 8020 is usually used in imperial systems while 4040 follows the metric system.

The confusion between 4040 and 8020 often comes from branding. “80203” is also the brand name of a popular aluminum extrusion supplier in the U.S., which uses imperial measurements. In contrast, 4040 usually refers to metric T-slot profiles used more commonly in Europe and Asia.

Comparison Table: 4040 vs 8020

| Feature | 4040 (Metric) | 8020 (Imperial) |

|---|---|---|

| Dimensions | 40mm x 40mm | 1" x 2" or 40mm x 80mm |

| Slot Size | 8mm | 1/4 inch (\~6.35mm) |

| Applications | Modular frames, enclosures | Framing, jigs, fixtures |

| System | Metric | Imperial |

So if you’re buying from a global supplier or planning overseas projects, always double-check whether your "8020" is a size or a brand.

How to determine aluminum extrusion size?

Choosing the right extrusion isn’t just about length — the profile’s width, slot size, and internal bore matter too.

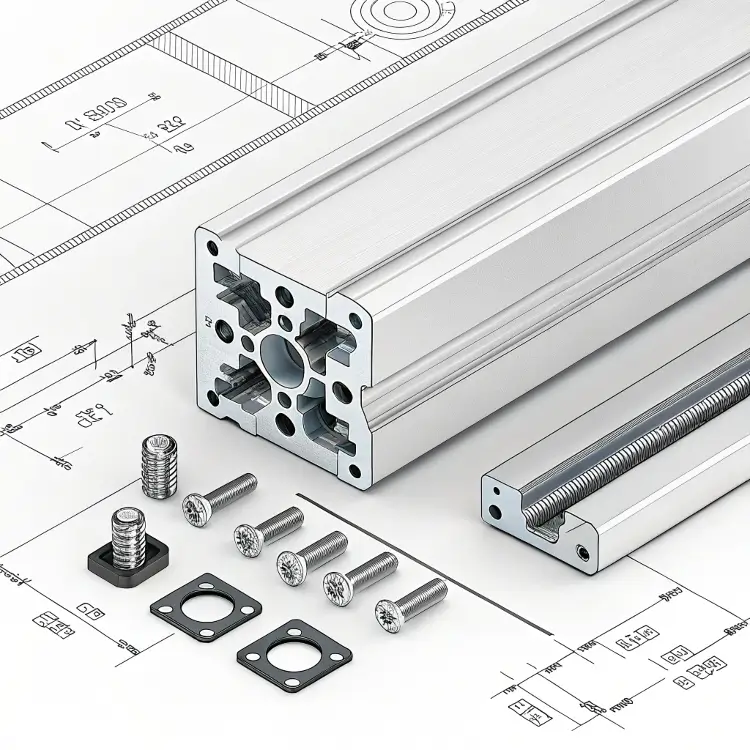

To determine aluminum extrusion size, measure the width and height of the cross-section, slot width, and the center bore diameter4. Always refer to technical drawings or CAD models.

I often help customers who received a profile with the wrong slot size5 or bore — and it’s usually because they assumed all 4040s are the same. But even within the same size class, there can be differences depending on the supplier or the extrusion series (light vs. heavy duty).

Key Measurements to Confirm

- Cross-sectional width and height: E.g., 40mm x 40mm.

- Slot size: Usually 6mm, 8mm, or 10mm depending on system.

- Center bore: To match fasteners like M6, M8, etc.

- Wall thickness: Affects strength and rigidity.

When ordering custom extrusions from Sinoextrud, we provide detailed CAD files and technical drawings, so your team can integrate them directly into your designs without guessing.

What size is 5050 aluminum extrusion?

Another confusing number? Yes — but once you know the pattern, it all makes sense.

5050 aluminum extrusion measures 50mm by 50mm. Like 4040, it’s a square T-slot profile, but with a larger footprint and potentially higher load-bearing capacity.

The 5050 profile is often used for heavier applications, such as large automation frameworks, industrial machine bases, and custom equipment housings. The larger size also allows for more slots or deeper channels, depending on the profile design.

Key Differences Between 4040 and 5050

| Feature | 4040 | 5050 |

|---|---|---|

| Dimensions | 40mm x 40mm | 50mm x 50mm |

| Load Capacity | Medium | Higher |

| Weight per meter | Lighter (\~1.5kg/m) | Heavier (\~2.2kg/m) |

| Applications | Light to medium duty | Medium to heavy duty |

If you’re not sure which size you need, think about what you’re building — machine guarding? Use 4040. Large frame for CNC? Go for 5050.

Conclusion

4040 aluminum extrusion is 40mm by 40mm, perfect for modular structures. But sizing varies, so always confirm technical specs before ordering.

-

This resource will provide you with precise dimensions and additional details about 4040 aluminum extrusion, crucial for your engineering projects. ↩

-

Learn about the metric T-slot standard to better understand how aluminum extrusions are categorized and utilized in various applications. ↩

-

This resource will help you discover the unique features and advantages of 8020 aluminum extrusions, crucial for your projects. ↩

-

Measuring the center bore diameter is essential for proper fastener fit. Learn the best practices for accurate measurement. ↩

-

Slot size can significantly impact assembly and functionality. Discover more about its importance and how to choose the right size. ↩