What is CNC machined aluminum parts?

In product development, quality control and speed can be hard to balance. If you work with aluminum parts, CNC machining might be the solution you’re looking for.

CNC machined aluminum parts are components made from aluminum alloys shaped by computer-controlled machines that cut with extreme precision.

Aluminum is lightweight, corrosion-resistant, and easy to machine. That makes it ideal for high-performance parts. CNC machining allows these parts to meet tight tolerances and complex geometries.

Even experienced engineers sometimes struggle to explain this clearly to their non-technical clients. Let’s break it down in simple terms.

CNC machined aluminum parts are aluminum components created by using CNC (Computer Numerical Control) machines to cut and shape raw aluminum material into precise final forms.

CNC machining involves taking a solid block of aluminum—often 6061 or 7075—and removing material using various tools until it becomes the shape you need. This is called subtractive manufacturing. The whole process is driven by digital CAD models. These files are translated into G-code, which the CNC machine reads to control tool paths, speeds, and feeds.

I often start by reviewing the customer’s 3D model. From there, we decide on the type of machine to use—3-axis, 4-axis, or 5-axis—depending on the complexity. Aluminum is one of the most commonly machined metals because it balances strength and machinability.

Here’s a comparison of popular aluminum grades we use:

| Aluminum Grade | Key Properties | Common Uses |

|---|---|---|

| 6061 | Good strength, weldable | Housings, brackets, enclosures |

| 7075 | Very strong, aerospace-grade | Aerospace, robotics, high-load parts |

| 5052 | Excellent corrosion resistance | Marine, electronics, sheet parts |

We keep these alloys in stock and choose based on customer priorities—whether they want better strength, corrosion resistance, or cost-efficiency.

How does CNC machining work for aluminum?

If you’ve ever waited weeks for a sample that didn’t meet your drawing, you know the pain. CNC machining changes that.

Aluminum CNC machining uses digital designs to guide cutting tools, shaping aluminum blocks into exact geometries with high accuracy and repeatability.

The process starts when a 3D CAD model is turned into CAM code (like G-code). That code controls the movement of cutting tools. Depending on the part’s complexity, we choose machines with different axes:

Types of CNC Machines We Use

| Axis Type | Capabilities | Best For |

|---|---|---|

| 3-axis | Moves in X, Y, Z | Flat or simple parts |

| 4-axis | Adds rotation around X-axis | Features on multiple sides |

| 5-axis | Rotates around two axes | Complex shapes and tight corners |

The machine then removes material layer by layer using tools like end mills, drills, or ball mills. We control everything from tool speed to coolant type to keep the aluminum cool and prevent warping.

Our operators monitor every run closely. With experience, we know when to adjust feeds or change cutting angles to avoid chatter marks or tool wear. That’s what keeps each part consistent.

What tolerances can be achieved?

Many customers ask: “Can you hold ±0.01mm?” The answer often depends on part size and geometry.

CNC machining can achieve tight tolerances for aluminum—typically ±0.01mm, and in some high-precision setups, even tighter.

Tolerances are the allowed amount of variation from the design. In aluminum machining, this is influenced by machine rigidity, material stress, tool sharpness, and temperature.

We usually divide tolerances into three categories:

Common Tolerance Ranges

| Precision Level | Typical Range | Applications |

|---|---|---|

| Standard | ±0.1mm | Basic brackets, covers |

| Medium | ±0.05mm | Consumer electronics, mounting frames |

| High Precision | ±0.01mm or tighter | Optical components, aerospace parts |

For most functional parts—like brackets or housings—±0.05mm is more than enough. But when we work on robotic arms or optical mounts, we go tighter. We use CMMs (Coordinate Measuring Machines) to inspect every critical dimension and provide a full inspection report when needed.

To achieve this consistency, we control material batches, tool wear, machine temperature, and even vibration in the shop.

What surface finishes are possible?

Many people think aluminum only looks like a raw metal block. But CNC parts can look polished, matte, or even glossy black.

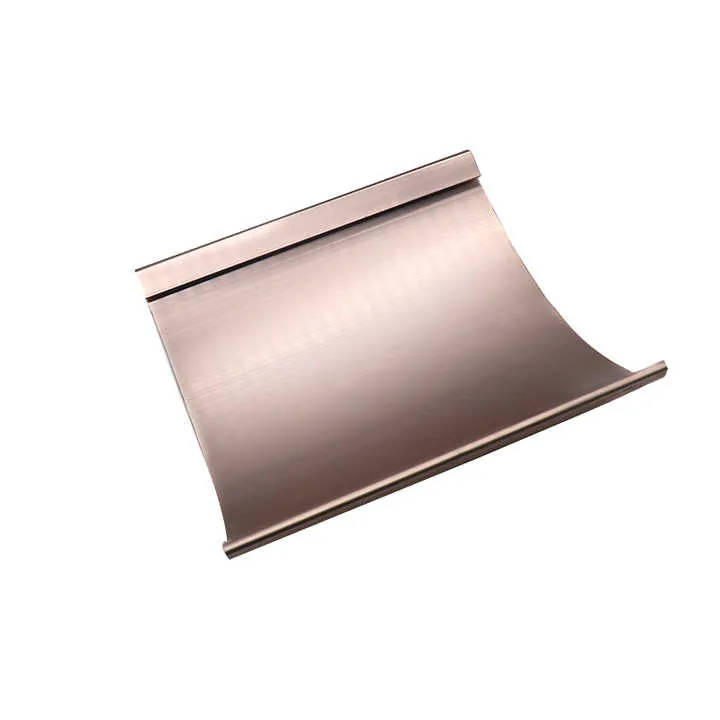

Aluminum CNC parts can have finishes like anodizing, bead blasting, brushing, polishing, powder coating, or chromate conversion coating.

Finishes aren’t just for looks. They help protect the part and enhance functionality. For example, anodizing improves corrosion resistance and allows color customization.

Here are common surface finishes we offer:

Surface Finish Options

| Finish Type | Appearance | Benefits |

|---|---|---|

| Anodizing (Type II) | Colored/matte | Corrosion-resistant, aesthetic |

| Hard Anodizing | Dark, thick coat | Wear-resistant, suitable for machinery |

| Bead Blasting | Matte, uniform | Hides tool marks, clean appearance |

| Brushed | Linear texture | Premium look for consumer products |

| Polished | Mirror-like shine | Decorative, used for logos or accents |

| Powder Coating | Smooth, colorful | Durable, scratch-resistant |

We usually recommend anodizing for most functional parts. It adds a protective layer and comes in colors like black, silver, red, blue, or gold. If your project involves outdoor use, we can guide you on coating thickness and salt spray resistance.

Which industries use CNC aluminum parts?

Some customers worry if CNC aluminum fits their market. In reality, it probably already does.

CNC aluminum parts are used across many industries—especially electronics, aerospace, automotive, medical, and industrial automation sectors.

Here’s how different industries use them:

Industries and Applications

| Industry | Applications |

|---|---|

| Consumer Electronics | Device enclosures, heat sinks |

| Aerospace | Brackets, housings, structural parts |

| Automotive | Gearbox housings, engine components |

| Medical Devices | Frames, surgical equipment casings |

| Robotics & Automation | Arm joints, custom mounts, sensors |

From our own experience, one robotics client in Germany needed ±0.01mm flatness on a sensor mounting plate. Another startup in the U.S. needed custom-colored, sandblasted cases for wearable electronics. Both found CNC aluminum the best option for low- to mid-volume production with tight specs.

Even within the same industry, needs differ. So we tailor the process—from alloy selection to final finish—based on customer goals and their market positioning.

Conclusion

CNC machining transforms aluminum into high-performance, custom components with tight tolerances and versatile finishes. It’s the go-to choice for industries that need quality and flexibility.