What is CNC Machined Aluminum?

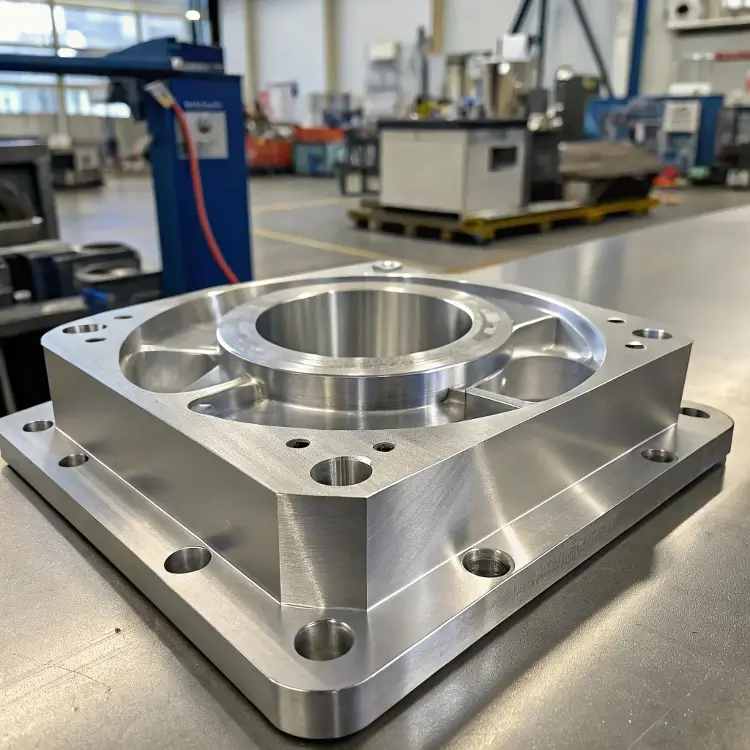

CNC machined aluminum is a high-precision metal part produced using Computer Numerical Control (CNC) machining techniques. This process uses automated machines that are controlled by a computer to cut, shape, and finish aluminum into specific shapes and sizes.

CNC aluminum is an excellent choice for producing parts that require high accuracy, tight tolerances, and complex designs. The ability to produce durable, lightweight, and cost-effective parts makes it ideal for industries like aerospace, automotive, and electronics.

CNC machining offers numerous advantages, such as speed, precision, and repeatability. The result is a high-quality aluminum part that fits the exact specifications required. Keep reading to explore whether CNC aluminum is a good choice for your project.

Is CNC Aluminum Good?

CNC aluminum is an excellent material for producing high-performance, precision parts. It’s known for its lightweight nature, strength, and versatility, making it a go-to choice for industries that need durable and accurate components.

CNC machined aluminum1 is widely used in various applications such as aerospace, automotive, electronics, medical devices, and more. Its high strength-to-weight ratio2 and corrosion resistance3 make it ideal for components that need to withstand harsh environments. Furthermore, CNC machining ensures precise tolerances, making aluminum parts consistently reliable.

The Benefits of CNC Aluminum

- Lightweight: Aluminum is much lighter than steel, making it ideal for industries like aerospace and automotive, where weight reduction is crucial.

- Corrosion Resistance: Aluminum has excellent resistance to corrosion, which increases the lifespan of parts used in outdoor and marine environments.

- Precision: CNC machining guarantees tight tolerances and high accuracy, which is essential for complex parts.

- Durability: Although lightweight, CNC aluminum is strong and durable, providing long-term reliability.

What is Machined Aluminium?

Machined aluminum refers to aluminum parts that are created through a machining process, such as CNC milling4 or turning. These processes remove material from a solid block of aluminum to create a specific shape or design.

Machining allows for the production of precise and complex parts that cannot easily be achieved with other manufacturing methods. Machined aluminum is often used when high precision, tight tolerances, and customized shapes are necessary. The process can be applied to a variety of aluminum alloys, which offer different characteristics based on the intended application.

Key Steps in Machining Aluminum

- Designing the Part: The first step involves creating a digital model of the part using CAD (Computer-Aided Design) software.

- CNC Programming: The design is then programmed into a CNC machine, which controls the movements and operations of cutting tools.

- Machining Process: The aluminum block is carefully cut and shaped into the desired component using different tools.

- Finishing: The part is polished or coated to achieve the desired surface finish.

What is the Difference Between Cast and CNC Aluminum?

The main difference between cast and CNC aluminum lies in the manufacturing process. Cast aluminum5 involves pouring molten aluminum into a mold, while CNC aluminum is made by subtracting material from a solid aluminum block using precise machining.

Cast Aluminum

- Cost-effective: Casting is typically less expensive than CNC machining for large-scale production.

- Ideal for Simple Shapes: Casting works well for creating large quantities of parts with simple shapes and less precision.

- Lower Precision: Cast aluminum parts are generally less precise than CNC machined parts, especially when it comes to tight tolerances.

CNC Aluminum

- High Precision: CNC machining offers high accuracy and the ability to create complex geometries with tight tolerances.

- Material Waste: CNC machining is more material-intensive as material is removed to create the part, whereas casting only uses the material that fills the mold.

- Flexibility: CNC machining can produce parts of virtually any shape, including intricate and customized designs.

| Aspect | Cast Aluminum | CNC Aluminum |

|---|---|---|

| Cost | Generally lower for large volumes | Higher due to precision |

| Precision | Lower, with more variation | High precision and consistency |

| Production Speed | Faster for large quantities | Slower but more customizable |

| Material Waste | Minimal | Higher due to material removal |

| Application | Simple shapes, large quantities | Complex and high-precision parts |

What is CNC Metal Machining?

CNC metal machining refers to the process of using CNC machines to shape metal parts. It involves subtracting material from a solid block of metal to achieve a desired shape, using precise movements controlled by a computer.

This process can be applied to a variety of metals, including aluminum, steel, brass, and titanium. CNC metal machining is essential for producing parts that require high precision, such as those used in aerospace, automotive, medical, and industrial applications.

Types of CNC Metal Machining

- CNC Milling: The metal workpiece is rotated as various cutting tools are applied to remove material. This method is used for parts with complex features.

- CNC Turning: The workpiece is rotated while a stationary tool removes material to create cylindrical parts.

- CNC Drilling: A drill bit is used to create holes in the workpiece with precise depth and diameter.

| Type of CNC Machining | Description | Applications |

|---|---|---|

| Milling | Removes material from a rotating workpiece with cutting tools. | Complex parts, prototypes |

| Turning | Rotates the workpiece while a tool removes material to form a cylinder. | Shafts, bushings, rings |

| Drilling | Uses a rotating bit to create precise holes in the workpiece. | Holes for fasteners, joints |

Conclusion

CNC machined aluminum is a versatile, high-precision material that provides durability, lightness, and corrosion resistance. Whether you’re creating complex parts or need precise machining, CNC aluminum offers a reliable solution for a wide range of industries.

-

Explore the diverse applications of CNC machined aluminum to understand its significance in various industries. ↩

-

Learn about the importance of high strength-to-weight ratio in materials and how it impacts design and performance. ↩

-

Discover the benefits of corrosion resistance in materials and how it enhances the longevity of components. ↩

-

Learn about CNC milling, a key technique in machining aluminum, to appreciate its role in creating complex parts. ↩

-

Learn about the benefits and limitations of cast aluminum, essential for making informed production choices. ↩