what is an aluminum extrusion die?

In aluminum extrusion, one of the most critical tools is often invisible in the final product: the die. It defines the shape and controls the flow of the material.

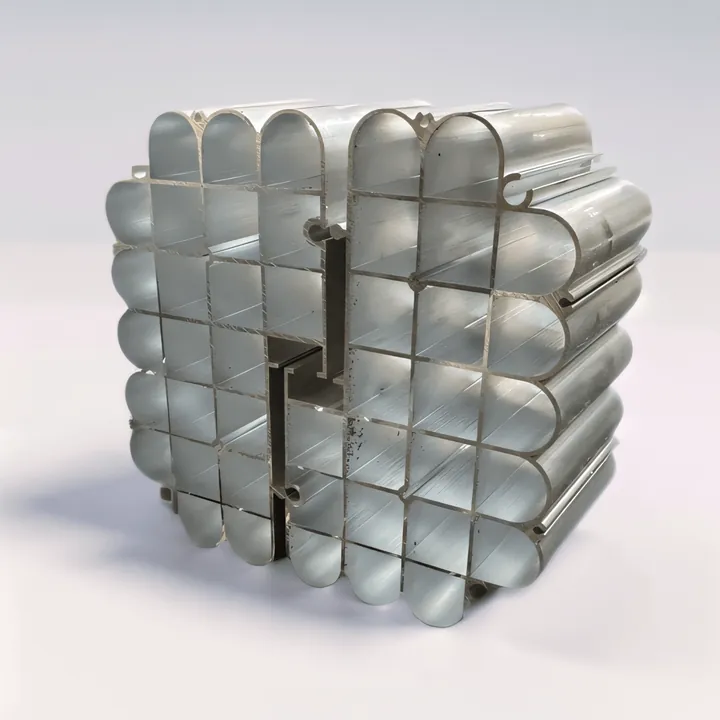

An aluminum extrusion die is a precision-engineered steel tool with a specific cut-out shape that molten aluminum is forced through, forming the profile’s cross-section.

This article explains how dies shape profiles, how design impacts quality, where dies are used in the press, and if they can be reused across different designs.

How does a die shape extrusion profiles?

It’s easy to assume that aluminum shapes come from molds, but extrusion works differently. Here, the die is everything.

The die gives the aluminum its profile by forcing it through a shaped hole under pressure, resulting in the desired cross-section.

Aluminum extrusion begins by heating a cylindrical billet until it’s soft enough to flow. The billet is pushed by a ram through the die—a flat steel disc with a precise opening shaped to match the final profile. The metal takes on the shape of that opening as it exits the press.

For solid profiles, the die has a simple opening. For hollow or semi-hollow profiles, the die includes mandrels and bridges that shape internal cavities. This design allows air and material to flow properly while maintaining the profile’s integrity.

The die must also control how the material flows. If it flows too fast in one area and too slow in another, the extrusion can warp, split, or show uneven surfaces. Every angle, channel, or rib in the die impacts final shape, strength, and consistency.

Summary of die influence on profile:

- Defines exterior and interior shapes

- Controls wall thickness and structural ribs

- Manages material flow and exit speed

- Sets initial surface texture and finish quality

The die opening does not affect the wall thickness of the extrusion.False

Wall thickness is precisely controlled by the die’s shape and must be engineered into the design.

The profile’s cross-section is created by forcing aluminum through the die’s shaped opening.True

The aluminum takes on the exact shape of the die’s cavity during extrusion.

Why die design affects quality?

If a die is not properly designed, the aluminum may still come out—but defects and variations will show up quickly.

Die design affects quality by managing how aluminum flows, cools, and forms—bad design can cause warping, cracking, uneven walls, or short die life.

A well-designed die ensures that all parts of the profile fill evenly and cool at the same rate. If the die doesn’t balance the flow correctly, the result might be bends, surface lines, or even cracks. That’s especially true for complex profiles with hollow spaces or variable wall thickness.

Thin sections cool faster than thick ones, which causes internal stresses. These differences can be minimized with precise die design. Features like support bridges, mandrels, and corner radii help distribute material more evenly.

Die design also affects tooling life. A weak die may crack or deform under high pressure. Hardened steel, cooling channels, and good support structures inside the die help maintain its shape over many runs.

Table: How design choices affect quality

| Die Design Feature | Quality Impact |

|---|---|

| Symmetry in flow paths | Reduces distortion and warping |

| Proper wall thickness | Prevents weak spots and collapse |

| Smooth internal corners | Avoids buildup or tearing |

| Balanced support system | Maintains die alignment and longevity |

A simple die always guarantees high-quality extrusions regardless of shape complexity.False

Complex shapes require advanced die design to maintain accuracy and material flow.

Careful die design improves the consistency and surface quality of extruded parts.True

Good design reduces internal stresses, avoids defects, and improves dimensional precision.

Where dies are mounted in presses?

The die isn’t floating in space—it’s mounted precisely inside the extrusion press. Understanding this setup helps explain how extrusion really works.

Dies are installed at the exit end of the extrusion container, held tightly by support plates so that the aluminum billet is pushed through them under pressure.

In an extrusion press, a container holds the heated billet. A hydraulic ram pushes the billet forward until it contacts the die. The die is mounted in a fixed position at the front of the press. It’s supported by several layers of tooling: backers, bolsters, and sometimes sub-bolsters.

These support tools do two things: they keep the die aligned and handle the immense pressure applied during extrusion—up to tens of thousands of PSI. Misalignment here can lead to off-spec parts or damage to the die and press.

The press is carefully calibrated so that the ram, billet, and die all sit perfectly in line. After each run, the die can be removed, cleaned, or replaced. Some presses are designed to switch dies quickly to improve efficiency for high-volume manufacturing.

Diagram summary (conceptual):

- Ram → Billet → Container → Die stack → Profile exit

The die is mounted at the back of the extrusion press.False

The die is installed at the front of the press, directly in the material flow path.

Proper die mounting ensures accurate alignment and consistent profile output.True

If the die is misaligned, the extrusion will be distorted or may fail entirely.

Can dies be reused across profiles?

Creating new dies is expensive, so the question naturally arises—can one die serve multiple designs?

Dies can sometimes be reused for profiles with minor differences, but significant shape or alloy changes usually require a new or modified die.

Each die is custom-made for a specific profile. The shape, thickness, and flow paths are tailored to that profile’s geometry. If another profile is almost identical—say it only differs by a mounting hole or a slight width change—the same die may be used with small corrections.

Some die systems allow for inserts or modular parts that can be swapped to change certain features. This is more common in standardized product lines where many profiles share a base geometry.

However, changing alloys, wall thickness, or adding hollows will likely need a new die. Different alloys flow differently under pressure and temperature, so a die optimized for 6063-T5 may not work well with 7075-T6.

Die reuse depends on several factors:

- Profile similarity

- Required tolerances

- Alloy used

- Production volume

- Cost vs time to create a new die

In large-scale production, having a dedicated die for each profile ensures better control and fewer defects.

A die can be reused for any profile regardless of changes in shape or alloy.False

Significant changes require new or adjusted tooling to meet quality standards.

Minor shape variations may allow die reuse if tolerances and alloys remain similar.True

Die reuse is possible when profiles share close geometry and material properties.

Conclusion

An aluminum extrusion die is a core tool that shapes profiles, manages metal flow, and controls quality from the very first moment of extrusion. A good die ensures the right shape, strength, and surface from the start. Knowing how dies work helps avoid mistakes and plan for accurate, cost-effective production.