What is a perforated metal ceiling?

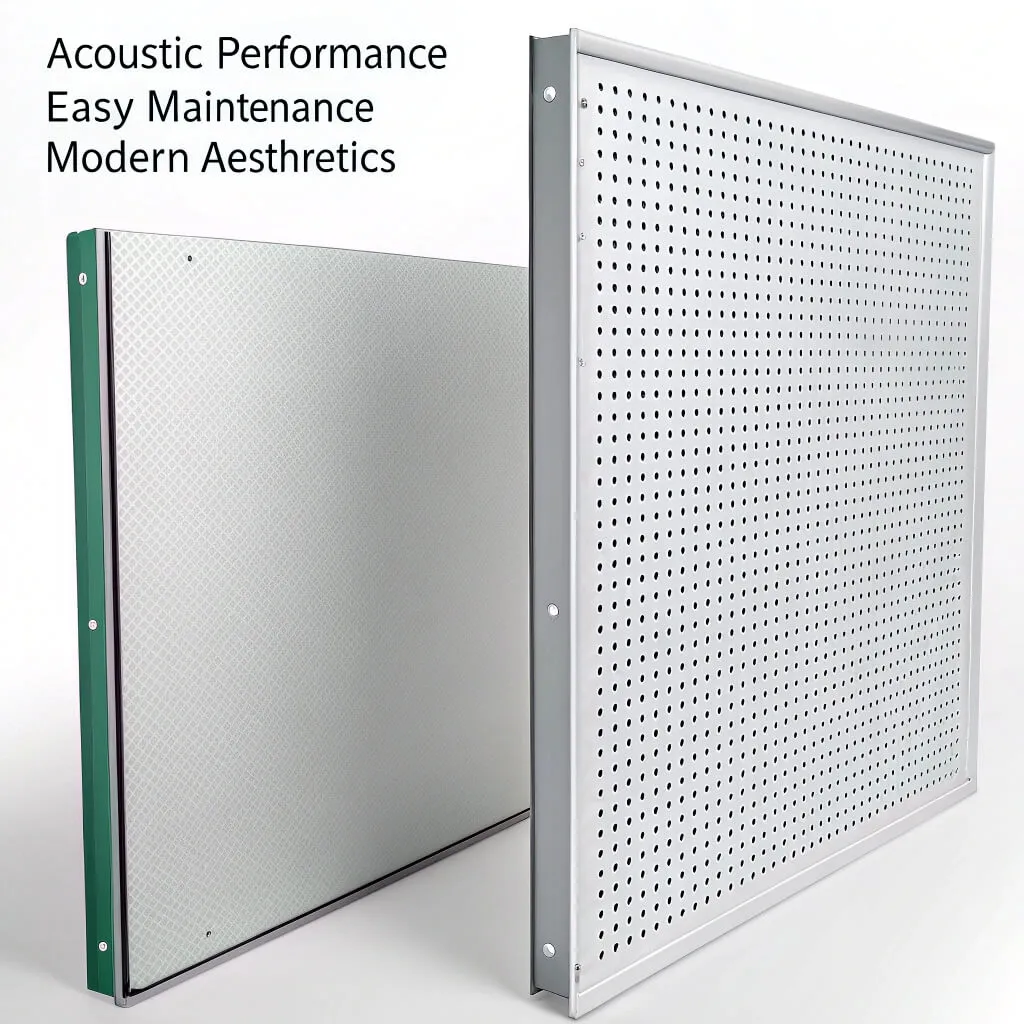

Perforated metal ceilings are gaining attention for their sleek design and excellent acoustic performance. But are they just about looks?

A perforated metal ceiling is a type of metal ceiling panel that has regularly spaced holes punched into the surface to improve sound absorption and aesthetic appeal.

They’re not just decorative — these ceilings play an important role in acoustics, ventilation, and modern design. Let’s break down their features and answer the most common questions buyers ask.

What is the purpose of perforated metal?

More than just a design choice, the perforations serve critical functional purposes.

Perforated metal is used in ceilings to enhance sound absorption, provide airflow, and offer a modern architectural look.

When sound hits a solid surface, it tends to bounce back, creating echoes. This is a problem in places like offices, airports, or shopping malls. Perforated metal ceilings, especially when combined with an acoustic fabric or insulation behind them, help absorb sound and reduce echo. The holes trap sound waves and reduce their intensity.

Perforated panels also allow air to flow through, which supports ventilation systems. This is useful in buildings that prioritize energy efficiency or need large HVAC systems. Plus, from a design point of view, perforated metal gives ceilings a modern, industrial style that architects love.

Common Applications of Perforated Metal Ceilings

| Application Area | Why It’s Used |

|---|---|

| Offices | Reduce noise and boost concentration |

| Airports | Handle large crowds and sound control |

| Hospitals | Hygiene-friendly and sound absorbing |

| Retail Stores | Stylish and functional ceiling design |

Why Architects Choose It

- Clean, uniform look

- Can hide cables and ducts

- Supports lighting integration

- Can be customized in shape and finish

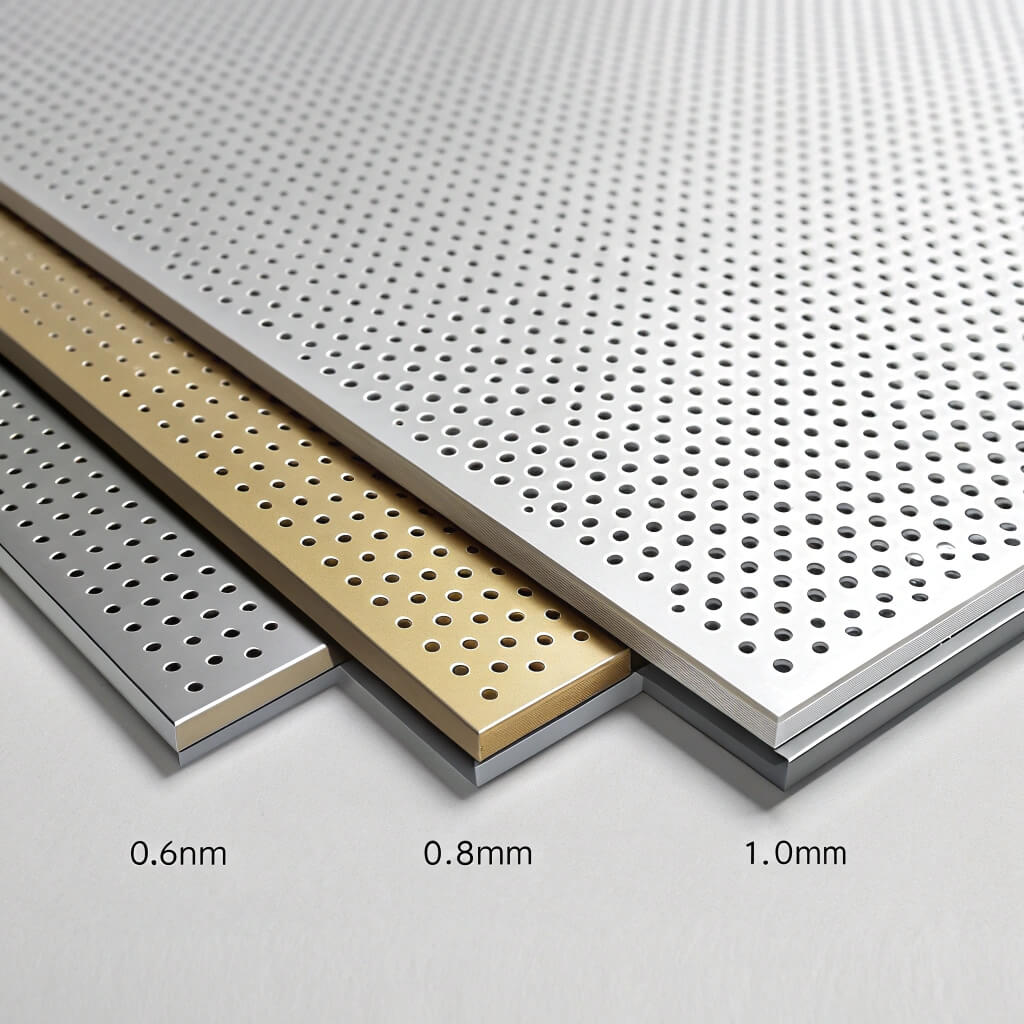

How thick is a perforated metal ceiling?

Thickness matters more than you might think when it comes to performance and durability.

The typical thickness of a perforated metal ceiling ranges from 0.5mm to 1.2mm, depending on design and material strength.

Thicker panels tend to be used in areas where structural strength is important, while thinner ones are suitable for purely decorative or acoustic purposes. The metal type also affects thickness — aluminum, for instance, is lightweight and can perform well even at lower thicknesses.

Most of the perforated metal ceilings I’ve supplied to my clients fall into the 0.6mm to 1.0mm range. This gives a balance of acoustic performance, ease of installation, and durability. Panels that are too thin may warp or dent easily, while overly thick panels add unnecessary weight and cost.

Recommended Thickness by Application

| Application | Suggested Thickness |

|---|---|

| Commercial Office | 0.6 – 0.8 mm |

| Public Transport Hub | 0.8 – 1.2 mm |

| Hospital Rooms | 0.5 – 0.7 mm |

| Shopping Malls | 0.6 – 1.0 mm |

Factors Affecting Thickness Choice

- Type of metal used (Aluminum vs. Steel)

- Acoustic insulation behind the panel

- Panel size and span distance

- Desired perforation pattern and density

Is perforated metal expensive?

Price is always part of the decision. But is it worth the cost?

Perforated metal is moderately priced, with costs influenced by material type, finish, perforation design, and quantity.

Perforated metal is more expensive than plain metal sheets because of the punching process, pattern customization, and sometimes the need for additional surface treatments. However, it is not necessarily "luxury priced." It offers excellent long-term value, especially when you factor in benefits like acoustic improvement, durability, and easy maintenance.

In my experience, the cost range varies a lot. A standard aluminum perforated panel might cost 20–30% more than a non-perforated one, but it saves on acoustic treatment and maintenance costs later. Powder coating or wood grain finishes add to the price but enhance aesthetics and protection.

Price Breakdown

| Factor | Impact on Cost |

|---|---|

| Material (Aluminum vs. Steel) | Aluminum is more costly but lighter |

| Surface Finish | Wood grain and anodizing increase cost |

| Hole Size & Pattern | Complex patterns cost more |

| Order Volume | Large orders reduce per-unit cost |

For B2B buyers like contractors or importers, negotiating based on long-term volume and consistent specs is the best way to keep the cost under control.

What are the two types of metal ceiling materials?

Let’s talk materials — what are the base metals used, and why do they matter?

The two main types of metal ceiling materials are aluminum and galvanized steel, each offering unique strengths.

Aluminum is lightweight, corrosion-resistant, and easy to work with. It is widely preferred in commercial and high-humidity environments. Galvanized steel, on the other hand, is heavier and stronger, often used when budget is tight or extra strength is needed.

In our factory, we produce most panels using aluminum because it performs well in coastal or humid climates. It also allows for more finishing options, like powder coating and wood grain transfer.

Comparison Table: Aluminum vs. Galvanized Steel

| Feature | Aluminum | Galvanized Steel |

|---|---|---|

| Weight | Light | Heavy |

| Corrosion Resistance | Excellent | Good (with coating) |

| Surface Finishing | Powder, Wood Grain, Anodize | Limited |

| Cost | Higher | Lower |

| Workability | Easy to cut and shape | Needs stronger tools |

Choosing the Right Material

Here’s how I usually help clients decide:

- If they need lightweight panels with decorative finishes, I recommend aluminum.

- If cost is a major factor and strength is more important than looks, steel works fine.

- For humid places like Singapore or coastal U.S., aluminum lasts longer.

Conclusion

Perforated metal ceilings offer more than just style — they provide acoustic, functional, and ventilation benefits. Choosing the right material, thickness, and design ensures both performance and beauty.