What is a liquid cooling plate?

Heat buildup is the enemy of performance. Whether it’s power electronics, lasers, or electric vehicles, heat can destroy efficiency. Liquid cooling plates offer a smart solution.

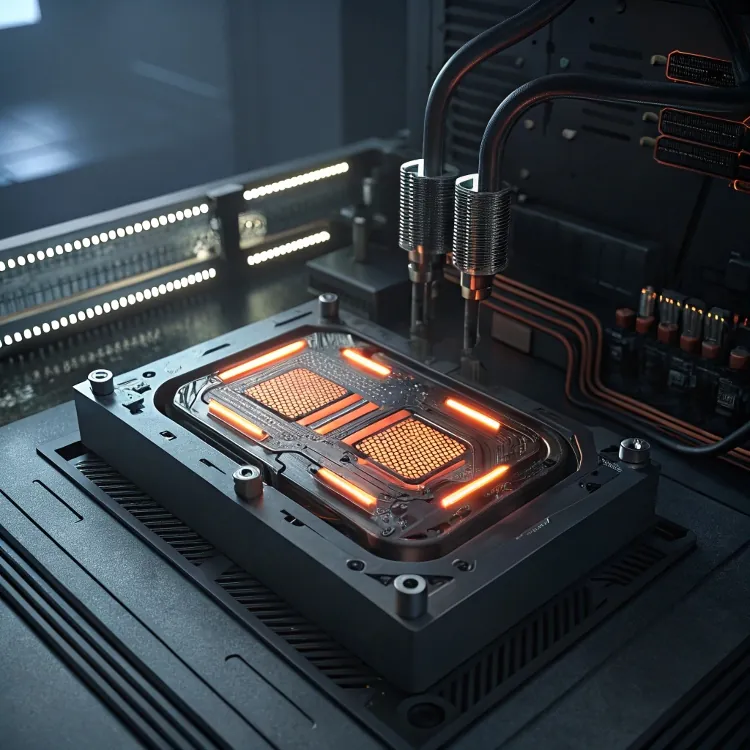

A liquid cooling plate is a metal component that removes heat by circulating coolant through internal channels in direct contact with heat-generating devices.

This technology helps control temperature in systems that generate a lot of heat but can’t rely on air cooling alone. Let’s break down how cooling plates work and where they’re most useful.

What does a cooling plate do?

When parts overheat, systems crash, or worse—fail permanently. A cooling plate prevents that.

A cooling plate1 transfers heat away from hot components to a liquid coolant2, which then carries that heat to a radiator or heat exchanger3.

The coolant moves through channels or tubes embedded in the plate. As it flows, it absorbs the heat from the metal surface. Then it exits the plate, carrying the heat away to a safer location. This continuous loop keeps devices cool even under heavy loads.

How Heat Moves in a Cooling Plate

- Heat source touches the metal plate.

- Heat conducts through the plate to the liquid.

- Liquid flows and carries the heat to an external cooler.

- Cooled liquid returns to repeat the cycle.

Compared to air cooling, this process is much more efficient—especially for high-performance equipment. I often explain this to buyers working in renewable energy and electric mobility, where every watt counts.

What are cold plates used for?

Not all industries need fans and vents. Some demand silent, compact, and powerful cooling.

Cold plates are used in EV batteries4, industrial lasers, power inverters, medical imaging equipment, and any system where air cooling isn’t enough.

In many of the custom projects I’ve worked on, cold plates5 serve in situations where there’s little airflow. For example, inside sealed boxes or outdoors in dusty conditions. They help protect sensitive electronics from overheating or environmental stress.

Key Applications of Cold Plates

| Industry | Application |

|---|---|

| Automotive | EV battery thermal management6 |

| Renewable Energy | Inverter cooling in solar/wind systems |

| Medical | MRI and CT scanner electronics |

| Telecom | Base station power modules |

| Industrial | Laser diode modules, welding systems |

What these industries have in common is the need for precise, reliable cooling—often in tight spaces. That’s where liquid-cooled aluminum plates outperform bulky fans or heat sinks.

What are the different types of liquid cold plates?

Not all cold plates are created equal. Designs vary depending on the thermal load, space, and fluid type.

The main types of liquid cold plates7 include tube-in-plate, flat tube, brazed, and friction stir welded8 designs. Each has its own benefits.

Common Cold Plate Types

| Type | Description | Best Use Case |

|---|---|---|

| Tube-in-Plate | Copper tube pressed into aluminum | Low to moderate heat loads |

| Flat Tube | Flat liquid channel with large surface contact | EV battery cooling |

| Brazed Plate | Internal channels sealed with vacuum brazing | Complex shapes, high performance |

| Friction Stir Welded | Strong aluminum joints for harsh environments | High-vibration or outdoor applications |

| CNC-Machined Channels | Custom coolant paths milled into the plate | Precision applications, medical devices |

In my factory, I often recommend friction stir welding for projects headed to humid or marine areas. It gives strong bonding and eliminates leakage risks—important for long-life products.

What do you put in a liquid cooling system?

You can’t just fill your cooling plate with water and hope for the best. The right fluid matters.

A liquid cooling system9 usually uses water mixed with glycol, or other engineered coolants that resist corrosion and support heat transfer.

Common Coolants in Cold Plate Systems

| Coolant Type | Pros | Common Use |

|---|---|---|

| Water | Excellent heat transfer | Short-term lab setups |

| Water-Glycol Mix | Anti-freeze, anti-corrosion | EVs, outdoor equipment |

| Dielectric Fluids | Non-conductive | Electronics, medical devices |

| Fluorinated Liquids | Chemically stable, safe | Aerospace, sensitive systems |

Choosing the wrong fluid can cause clogs, rust, or even system failure. That’s why I always advise clients to test fluids under real conditions. And if you’re using aluminum cold plates like ours, avoid acidic fluids that can eat into the metal.

Conclusion

Liquid cooling plates keep heat under control where air cooling fails. They are powerful, flexible, and essential in today’s high-performance industries.

-

Understanding the function of a cooling plate is crucial for optimizing thermal management in high-performance systems. Explore this link for detailed insights. ↩

-

Liquid coolants play a vital role in heat transfer efficiency. Discover more about their properties and applications in cooling systems. ↩

-

Heat exchangers are essential for effective cooling. Learn how they function and their importance in various applications. ↩

-

Learn about the critical role of cold plates in EV battery thermal management, ensuring safety and efficiency. ↩

-

Explore how cold plates enhance cooling efficiency in industries like automotive and medical, ensuring optimal performance. ↩

-

Discover the significance of thermal management in electronics and how it prevents overheating and extends device life. ↩

-

Explore this resource to understand the various applications and benefits of liquid cold plates in thermal management. ↩

-

Discover the advantages of friction stir welded cold plates for high-vibration and outdoor applications. ↩

-

Explore this link to understand the components and fluids essential for an effective liquid cooling system. ↩