What is a Clip-In Ceiling System?

Looking for a clean, modern ceiling solution that hides everything above? You’re not alone—many of our clients want that seamless look with none of the hassle.

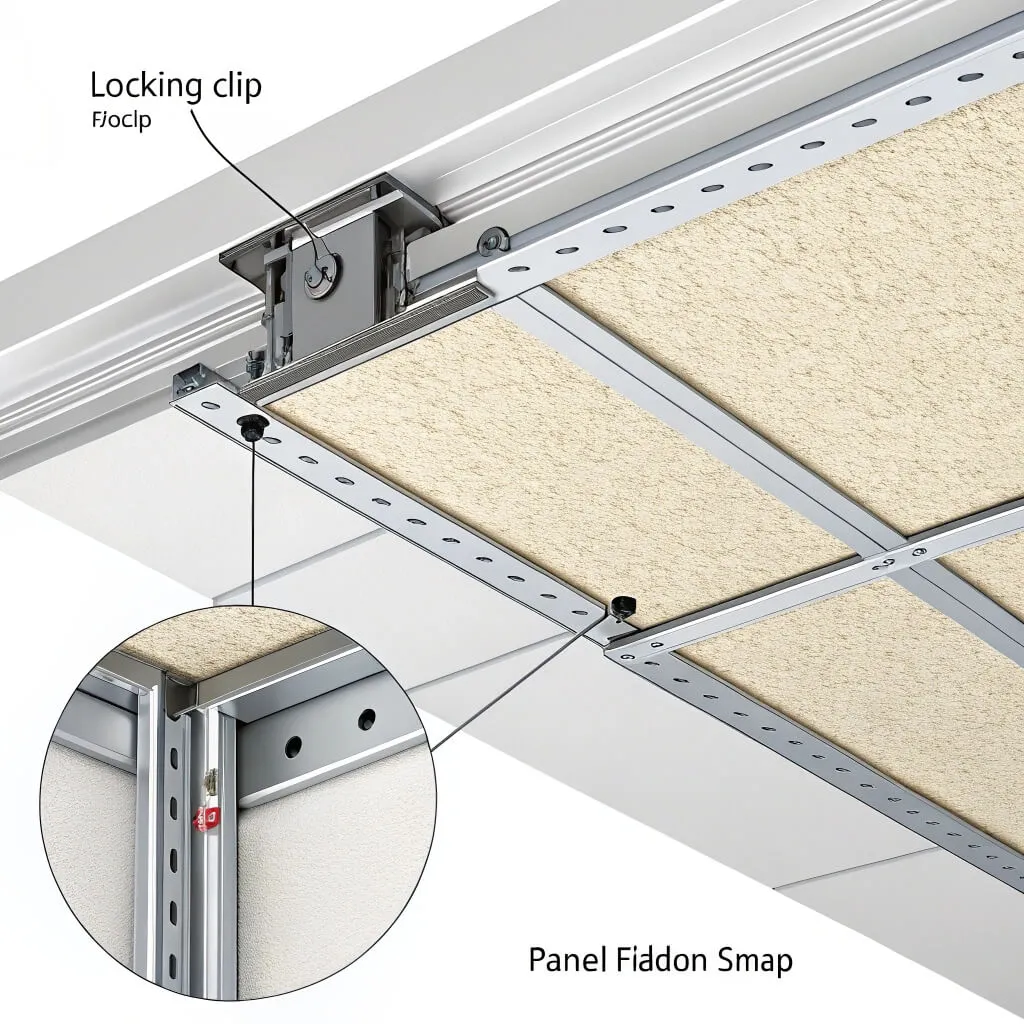

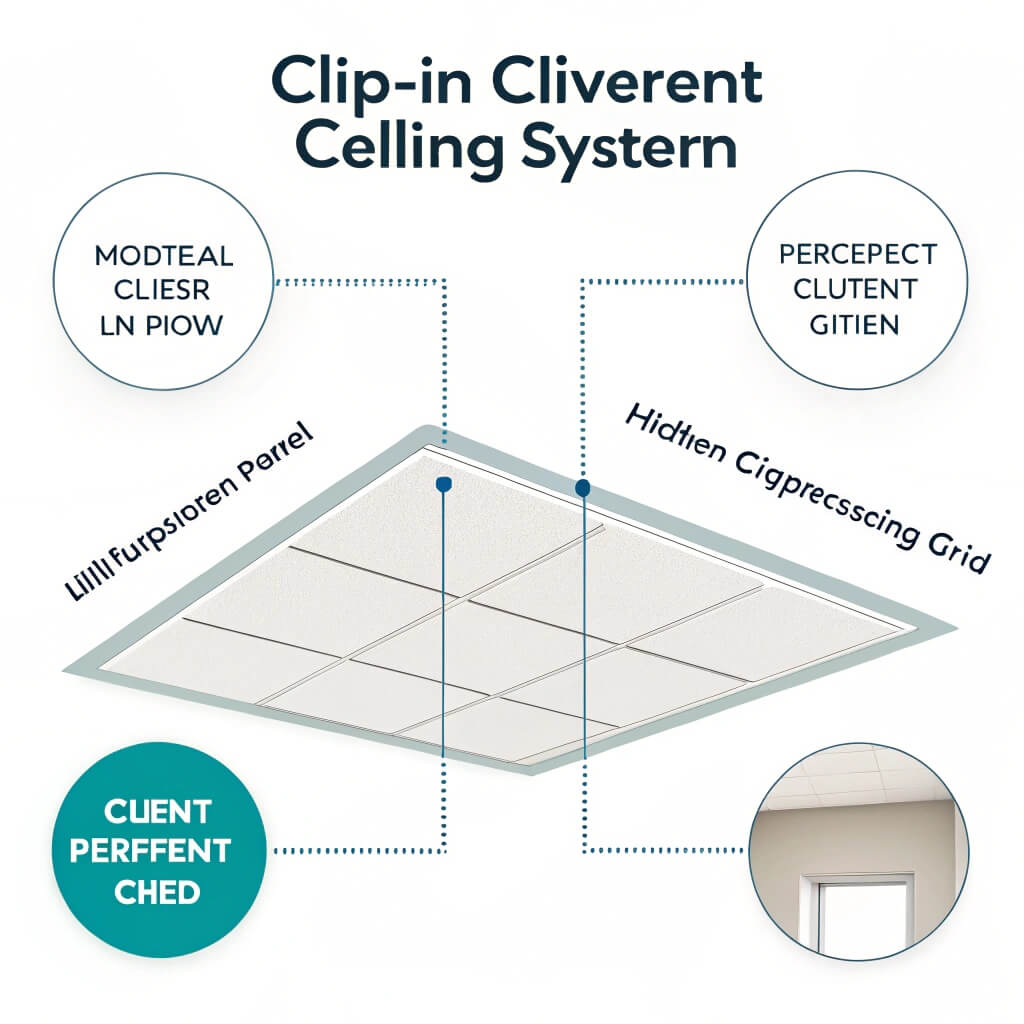

A Clip-In Ceiling System is a metal ceiling solution where panels snap into a concealed suspension system, providing a flush and streamlined surface.

This type of ceiling is especially popular in commercial settings where both aesthetics and access to infrastructure above the ceiling are important. Let’s break it down.

What are ceiling clips used for?

Frustrated with ceiling panels that shift or sag over time? Ceiling clips might be the simple answer.

Ceiling clips are used to securely attach ceiling tiles or panels to a concealed suspension system, preventing movement and ensuring a clean, fixed appearance.

Ceiling clips lock the panels into place. They allow for easy removal when needed, but most of the time, they stay firmly in position. This makes them ideal for spaces like airports, hospitals, or offices where ceilings are not often accessed but must remain stable.

Types of Ceiling Clips

| Clip Type | Description | Best Used For |

|---|---|---|

| Spring Clips | Snap into suspension rails automatically | Quick installs |

| Butterfly Clips | Expand to hold panel securely | Acoustic panels |

| Hanger Clips | Suspend ceiling grids from structural deck | Heavy-duty industrial ceilings |

Using the right clips also affects acoustic performance, ease of installation, and long-term durability. I always recommend choosing clips compatible with both your panel type and your suspension grid.

What is the difference between clip in and lay in?

Ever wonder why some ceilings look totally smooth while others show a visible grid? The difference lies in the system.

Clip-In ceilings have hidden suspension systems with panels that snap into place, while Lay-In ceilings rest on top of a visible T-bar grid.

Let’s break it down even further.

Comparison Table

| Feature | Clip-In System | Lay-In System |

|---|---|---|

| Appearance | Seamless, no visible grid | Grid is clearly visible |

| Accessibility | Tools needed to remove panels | Easy panel lift-out |

| Installation Complexity | More precise, slower | Faster and simpler |

| Design Flexibility | High, suitable for modern finishes | More traditional aesthetic |

| Maintenance Access | Slower, less frequent access required | Frequent access, fast maintenance |

I often help clients choose between the two depending on their priorities. If the focus is on high-end appearance, we go with clip-in. If quick access and budget are key, lay-in is the better choice.

How to install Snapclip suspended ceiling system?

Not sure how to get started with installing a Snapclip system? It’s easier than it looks—but only if you follow the right steps.

To install a Snapclip suspended ceiling, attach the Snapclip grid system to the ceiling, then snap panels upward into place using the integrated clips.

Here’s a basic guide I usually send to new clients:

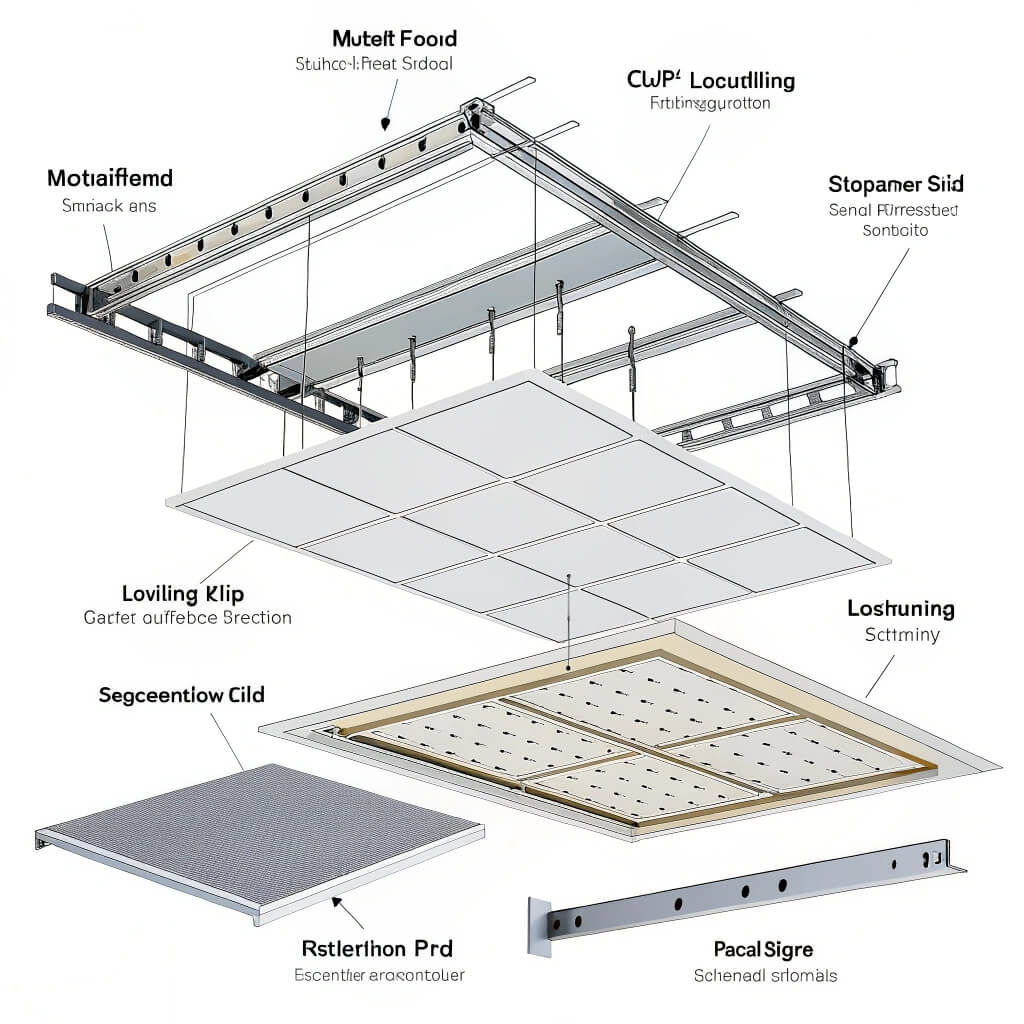

Step-by-Step Installation Process

-

Measure and Mark

Measure ceiling dimensions. Mark the perimeter on all walls using a laser level or chalk line. -

Install Wall Angles

Secure perimeter wall angles with screws. These will support the Snapclip grid. -

Suspend Main Runners

Attach hanging wires to the ceiling structure. Space them 1200mm apart and level carefully. -

Add Cross Tees

Insert cross tees perpendicular to the runners to form a grid layout. -

Snap Panels into Place

Lift panels and press upward until clips engage. You’ll hear a click when it’s locked in. -

Final Checks

Inspect alignment and level. Adjust suspension wires if needed.

The key is accuracy in the early steps—everything after that is smooth. I recommend using laser levels for a truly professional finish.

What is the most commonly used ceiling system?

Looking for the safest bet? Many architects and contractors ask me what’s “standard” when starting a new project.

Lay-In ceiling systems with T-bar grids are the most widely used ceiling system worldwide, especially in commercial and office spaces.

They’re used in schools, offices, retail spaces—almost everywhere. The reasons are clear: they’re easy to install, cost-effective, and give quick access for maintenance.

Why Lay-In Is So Common

- Cost Efficiency: Components are widely available and low cost.

- Ease of Maintenance: Just lift out a tile to access HVAC or electrical systems.

- Flexibility: Tiles can be swapped or upgraded without dismantling the grid.

- Acoustic Options: Many lay-in tiles come with sound-absorbing properties.

But popularity doesn’t always mean suitability. If you want a clean, high-end look or have specific project constraints, clip-in systems may still be the better choice.

Conclusion

Clip-in ceiling systems offer a seamless, modern look while lay-in systems provide practicality and ease. Choosing the right one depends on your project’s priorities.