What Does Anodizing Aluminum Do?

Anodizing aluminum is a process that uses electrochemical treatment to increase the thickness of the aluminum oxide layer on the surface of the aluminum. This process not only improves the durability of the aluminum but also enhances its appearance.

Anodizing aluminum creates a corrosion-resistant and durable surface by thickening its natural oxide layer. It allows for greater protection, better finish quality, and increased aesthetic appeal of the material.

The anodizing process changes the structure of the metal at the surface level, making it more resistant to wear, corrosion, and environmental damage. Let’s dive deeper into how anodizing works and its various impacts.

What Is the Purpose of Anodizing Aluminum?

Anodizing aluminum is primarily done to increase its corrosion resistance1, improve its appearance, and make it more durable. The process forms a thick, protective oxide layer on the surface of the aluminum, which is highly resistant to environmental factors like moisture and air.

The purpose of anodizing aluminum2 is to enhance its longevity, improve its aesthetic qualities, and provide protection against environmental damage. This makes anodized aluminum perfect for use in various industries such as construction, automotive, and even electronics.

Dive deeper into the purpose:

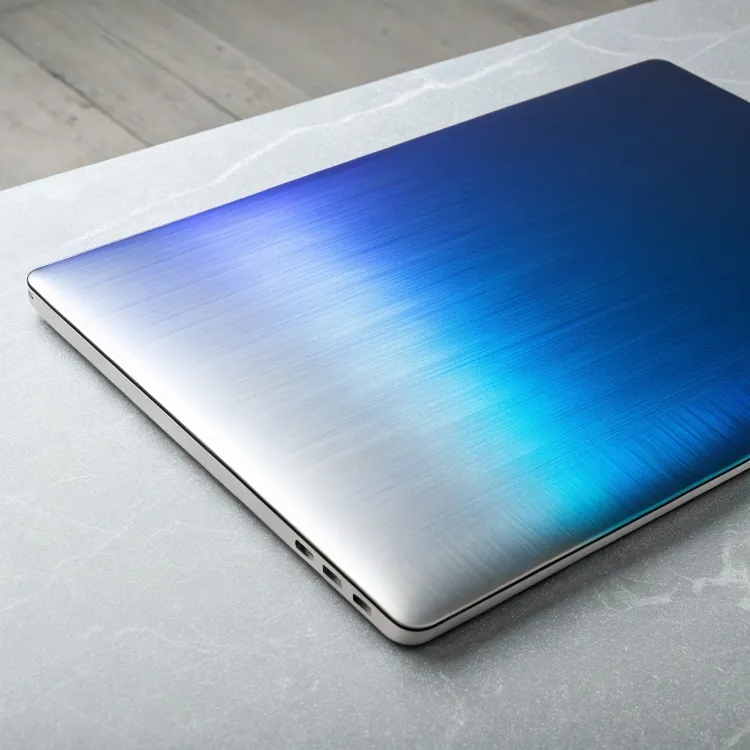

Anodized aluminum is commonly used in industries like construction, automotive, and electronics due to its combination of aesthetic and functional properties. For example, in the construction industry, anodized aluminum is used in windows and doors for its resistance to weathering, while in the automotive sector, it provides a sleek, polished finish that resists scratches and corrosion. The anodizing process also allows for custom coloring, which is why anodized aluminum can be found in various colors in consumer products, like smartphones or kitchen appliances.

Moreover, anodizing increases the aluminum’s surface hardness3. This is critical for applications where wear and tear are expected, such as in machinery parts or high-traffic areas. Not only does anodizing protect the aluminum, but it also adds a unique look that cannot be achieved by just polishing the metal.

What Is the Downside of Anodized Aluminum?

While anodized aluminum has many benefits, there are some downsides to consider. One of the main drawbacks is that anodizing does not make the aluminum completely scratch-resistant. Though it significantly improves durability, the oxide layer can still be scratched or damaged under extreme conditions.

The downside of anodized aluminum is that it can still get scratched or damaged4 under harsh conditions, and its color can fade5 over time. Additionally, anodizing may require additional care and maintenance to maintain its appearance and effectiveness.

Dive deeper into the downsides:

While anodizing aluminum provides protection, it’s not an impenetrable shield. The surface layer that forms during anodizing is relatively hard, but it is still susceptible to damage. For example, anodized aluminum can be scratched by hard objects or abrasive materials. Over time, the anodized surface may lose its color or luster, especially if exposed to sunlight for prolonged periods, as the color can fade5 due to UV damage.

Another issue is that anodizing is not always uniform, especially with irregularly shaped pieces, which can result in uneven coloring. Additionally, the anodizing process adds an extra layer to the metal, which could slightly change its overall dimensions. This might be a concern for projects where precise measurements are critical. Finally, anodizing is a time-consuming process, which could increase production costs, especially for large batches of parts.

Does Anodizing Aluminum Make It Stronger?

Anodizing aluminum does not inherently make the aluminum itself stronger in terms of its core strength or toughness. However, it does make the surface of the aluminum more durable and resistant to environmental damage, such as corrosion, scratches, and wear. The anodized surface is harder than untreated aluminum, which makes it more resistant to abrasions.

Anodizing aluminum6 enhances surface durability7, but it does not directly increase the overall strength of the metal itself. Instead, it focuses on improving the protective properties and aesthetic qualities of the aluminum’s surface.

Dive deeper into the effect on strength:

While anodizing creates a harder surface layer, the structural strength of the aluminum itself remains the same. The anodized layer acts as a protective barrier, preventing corrosion and reducing wear over time. In applications where the aluminum is exposed to harsh environments or mechanical stress, anodized aluminum performs better than untreated aluminum because it resists damage. However, in terms of pure structural strength, anodizing does not increase the aluminum’s core metal properties.

For instance, if aluminum is used for structural supports or load-bearing components, anodizing won’t make it any stronger. The metal’s inherent strength remains defined by its alloy and processing, not by the anodizing process. But if you’re looking to protect aluminum surfaces from scratching or environmental damage, anodizing certainly offers an improvement in durability.

What Are the Benefits of Anodizing Aluminum?

The benefits of anodizing aluminum are numerous, and they make it a popular choice for a wide range of applications. Anodizing enhances the surface of aluminum, providing it with several advantages, including increased corrosion resistance, improved aesthetic appearance, and enhanced surface hardness.

The main benefits of anodizing aluminum include improved corrosion resistance8, increased surface durability, and the ability to customize color and finish. It also allows the metal to retain its natural metallic finish while adding a layer of protection.

Dive deeper into the benefits:

-

Corrosion Resistance: Anodizing increases aluminum’s ability to withstand corrosion by creating a thicker oxide layer on its surface. This is particularly valuable for products exposed to outdoor elements, as anodized aluminum can resist moisture, salt, and other corrosive factors much better than untreated aluminum.

-

Durability: Anodized aluminum is more durable and scratch-resistant compared to its non-anodized counterparts. This makes it an ideal choice for products that experience wear and tear, such as machinery components or building materials.

-

Customizability: Anodizing can be done in a variety of colors, allowing for aesthetic flexibility in product design. The color is embedded within the oxide layer, which means it won’t chip or peel off like paint or powder coatings.

-

Sustainability: Anodized aluminum is also more environmentally friendly than some other finishes, as the anodizing process does not involve toxic chemicals or produce hazardous waste. Moreover, the anodized finish can last longer, reducing the need for replacement parts and minimizing environmental impact over time.

-

Ease of Maintenance: The anodized surface is more resistant to staining and easier to clean than untreated aluminum, which requires more maintenance. This can be a major benefit for products exposed to high levels of dirt, grease, or chemicals.

Conclusion

Anodizing aluminum provides significant benefits like enhanced durability, corrosion resistance, and improved aesthetics. While it doesn’t make the material stronger, it does add value by making it more resistant to damage and more customizable for various applications.

-

Learn how anodizing significantly boosts aluminum’s resistance to corrosion, making it ideal for harsh environments. ↩

-

Explore the benefits of anodizing aluminum to understand how it enhances durability and aesthetics in various applications. ↩

-

Discover how anodizing increases surface hardness, crucial for applications requiring durability and wear resistance. ↩

-

Learn about the factors that can lead to scratches or damage on anodized aluminum to better protect your investments. ↩

-

Explore how UV exposure impacts the longevity and appearance of anodized aluminum to ensure your projects maintain their aesthetic appeal. ↩ ↩

-

Exploring this resource will provide insights into how anodizing enhances aluminum’s durability and protective features. ↩

-

This link will explain the science behind anodizing and its impact on aluminum’s surface durability, crucial for various applications. ↩

-

Understanding corrosion resistance in anodized aluminum can help you appreciate its longevity and durability in various applications. ↩