What defines OEM aluminum bending services?

I used to think aluminum bending was just about curving metal. But after working with OEM clients for years, I realized it’s a whole system—with quality, design, volume, and communication at the core.

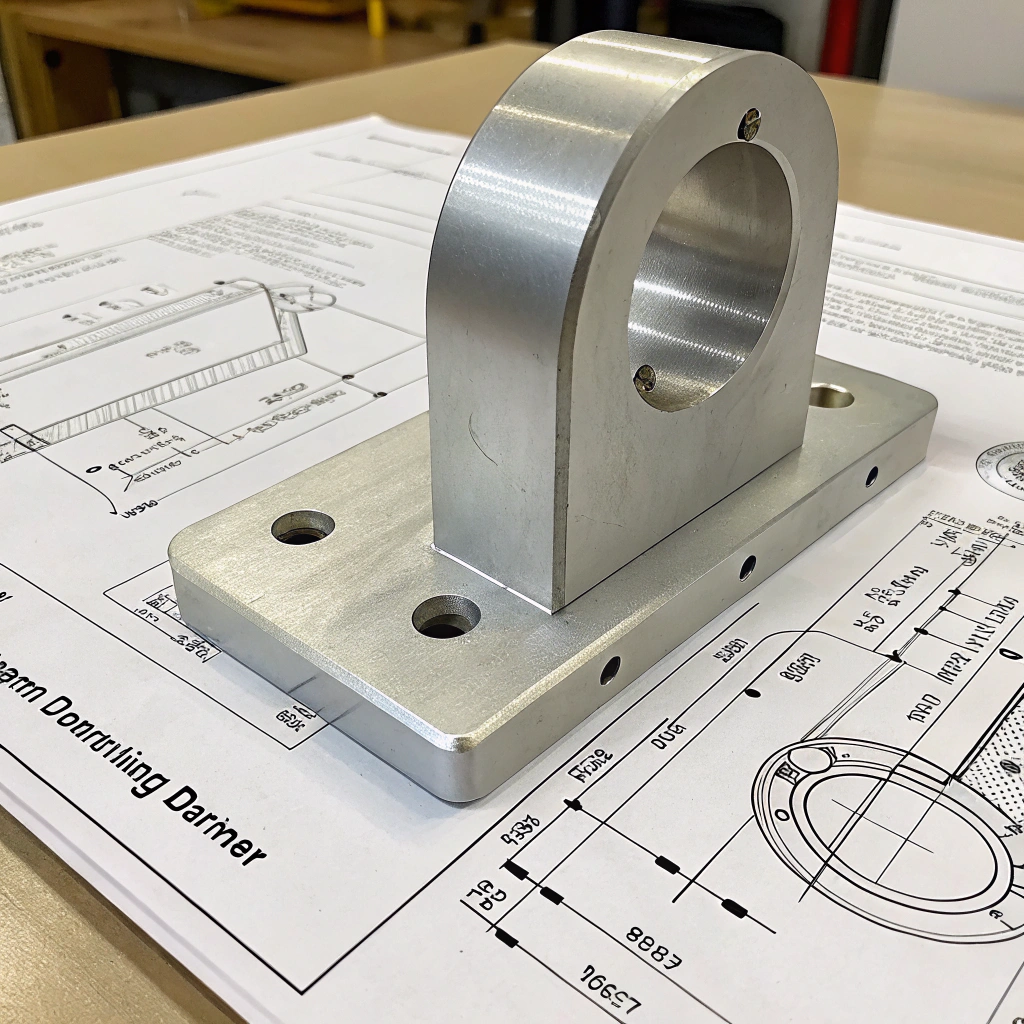

OEM aluminum bending services focus on producing precision-bent aluminum components for integration into finished products, tailored to meet the design, volume, and quality needs of original equipment manufacturers.

If you’re building something bigger and aluminum bending is just one piece of the puzzle, you’re in the right place.

What defines OEM aluminum bending services?

Most people think aluminum bending is a simple factory task. But in OEM work, it’s about much more. I’ve worked on projects where a bent aluminum bracket had to align within ±0.2mm in a medical device. That’s not just “bending”—that’s engineering.

OEM aluminum bending involves contract manufacturing of bent aluminum parts tailored to OEM specifications, ensuring repeatability, quality control, and production scalability.

Here are the defining elements I always look for in a true OEM bending service:

1. Built for Integration

OEM parts are not end products. They are components that fit inside something else. That means every dimension, angle, and surface must be accurate, consistent, and ready for assembly.

2. Engineering Support

OEM bending services don’t just follow drawings. They help optimize your design so it can be bent better, with fewer defects and lower cost.

3. Repeatable Quality

OEMs need consistency across 1,000 or 100,000 parts. Tolerances, finishes, strength—all must remain stable across batches. That’s why we follow documented processes and inspection protocols.

4. End-to-End Services

From prototyping to tooling, bending, machining, surface treatment, assembly, and packaging—OEM bending providers usually offer or coordinate every step.

| OEM Bending Feature | What It Means | Why It Matters |

|---|---|---|

| Design review | We help optimize your drawings | Reduces defects and cost |

| Certified processes | ISO, RoHS, REACH compliance | Required for many industries |

| Custom tooling | Fixtures, dies, jigs | Needed for complex geometries |

| Surface finish options | Anodizing, powder coating, brushing | Match end-product specs |

| Volume scalability | From prototype to mass production | Aligns with product lifecycle |

OEM aluminum bending services must ensure consistent quality across all production batches.True

OEM applications demand high repeatability to fit into larger assemblies without variation.

OEM aluminum bending is only used for decorative parts.False

OEM bent parts are structural and functional components used in machinery, electronics, and industrial products.

How do OEM services support product design needs?

The first time I worked with an automotive OEM, they sent a design for a heat shield with five bends and two compound angles. I had to call them back and say: "This can’t be bent without wrinkling unless we change the sequence or add a relief."

OEM aluminum bending services support product design through design for manufacturability (DFM) analysis, material selection advice, tolerance definition, and prototyping.

I never just bend what’s on the drawing. Here’s what I offer my OEM clients during the design phase:

Design for Manufacturability (DFM)

Many times, I catch problems before they cost money. Tight bend radii, conflicting flange overlaps, or material that can’t handle sharp angles—these are all things I help fix early.

Alloy Selection Advice

If a customer needs corrosion resistance, I suggest 6063-T5. For high strength, 6061-T6. For high ductility, 5052. Picking the right alloy avoids cracking and distortion.

Prototyping and Testing

We almost always build a prototype or a first article. It lets us test bend angles, surface integrity, and fitment before committing to mass production.

Tooling Analysis

Sometimes we need mandrels or special dies. I inform OEMs early so they can factor that into cost and timeline.

| Design Support Element | Benefit |

|---|---|

| DFM Review | Prevents production issues |

| Prototype Parts | Verify function and fit |

| Material Consultation | Improve performance and reduce cost |

| Bend Simulation | Avoid cracking or deformation |

Tolerance Management

I help OEMs define which dimensions are critical. That lets us focus QA on the right specs and keep costs in check.

Design for manufacturability is a key part of OEM aluminum bending support.True

OEM bending providers work closely with clients to ensure parts can be reliably manufactured at scale.

OEM aluminum bending services do not offer advice on material selection or tolerances.False

Material choice and tolerances directly affect bend quality, so OEM services often help optimize them.

How to work with OEM bending partners?

Good partnerships make or break OEM success. I’ve worked with companies that give me half-baked sketches—and others who hand over a complete package with CAD, tolerance specs, and finish requirements. Guess which one gets faster, better results?

To work effectively with OEM aluminum bending partners, provide complete specifications, communicate design intent clearly, request prototypes, and establish a consistent feedback and approval loop.

Here’s how I like to structure collaboration:

Step 1: Prepare Clear Documents

-

3D model + technical drawing

Include all angles, bend radii, wall thickness, hole placements, and tolerance zones. -

Material and surface finish

Be specific about the alloy and any anodizing or powder coating. -

Quantity and schedule

Is this a one-time job or ongoing production? Include target delivery dates.

Step 2: Schedule a Design Review

This is when we confirm if your design can be bent efficiently. I usually suggest minor changes that can reduce cost or prevent quality problems.

Step 3: Request a First Article

Before mass production, I send a small sample run for approval. We tweak the process based on your feedback.

Step 4: Finalize QC and Logistics

We agree on tolerance limits, quality checkpoints, packaging needs, and shipping method.

| Task | OEM Responsibility | Supplier Responsibility |

|---|---|---|

| Provide accurate drawings | ✅ | — |

| Offer DFM feedback | — | ✅ |

| Approve first article | ✅ | — |

| Follow bend standards | — | ✅ |

| Track delivery timeline | ✅ | ✅ |

Providing a 3D model and full technical drawing helps streamline the OEM bending process.True

Complete data reduces ambiguity and speeds up design reviews, quoting, and production.

It is acceptable to make design changes after production starts without informing the supplier.False

Uninformed design changes can cause defects, delays, or rework costs.

What volumes are typical in OEM aluminum bending contracts?

When OEMs first contact me, their biggest question is usually: “Can you handle our volume?” My answer depends on what they call “volume.”

OEM aluminum bending contracts typically cover a wide volume range, from 10-piece prototypes to over 100,000 units for mass production, depending on product complexity and industry.

Here’s how I categorize volumes:

Prototype / Pre-production (10–100 pcs)

Useful for product testing or pilot lines. No tooling investment needed unless geometry is complex.

Low Volume (100–1,000 pcs)

Applies to specialized equipment or niche products. Usually flexible on tolerances and lead time.

Medium Volume (1,000–10,000 pcs)

Common in lighting, furniture, and HVAC parts. Often includes custom tooling and dedicated QA steps.

High Volume (10,000+ pcs)

Mostly automotive, construction, or appliance components. Requires automation, tooling amortization, and logistics planning.

| Volume Type | Typical Industries | Notes |

|---|---|---|

| Prototype | Medical, Aerospace | Small batches, flexible changes |

| Low Volume | Industrial Machines | May skip custom tooling |

| Medium Volume | LED Housing, Furniture | Balances cost and speed |

| High Volume | Auto Parts, Rail Systems | Stable designs, repeat orders |

Volume Considerations

- Tooling cost: Higher volumes justify custom jigs or dies.

- QC scale: Larger volumes need structured QA and traceability.

- Batch size: Sometimes OEMs order 3,000 pcs every quarter instead of 12,000 at once.

- Flexibility: Low volume offers design flexibility; high volume prioritizes efficiency.

OEM aluminum bending volumes can range from as low as 10 to over 100,000 pieces.True

Different industries and product stages require different scales, from prototypes to full production.

OEM aluminum bending is only viable for orders over 10,000 pieces.False

Many OEM jobs involve low to medium volumes, especially in industrial or custom sectors.

Conclusion

OEM aluminum bending is more than shaping metal—it’s about understanding your product, supporting your design, and delivering consistent quality at the right scale. When both sides collaborate, great things get built.