CNC Machining China: Manufacturers & Industry Guide

Частина 1: Розмір та зростання ринку

China’s CNC machining industry has grown into one of the largest in the world. It started as a supporting sector for automotive and electronics, but it has expanded to aerospace, medical, and renewable energy. The industry benefits from rapid industrialization and the strong need for high-precision parts.

The market size is significant, with billions of dollars in output each year. CNC machining is no longer limited to large corporations; small and medium enterprises are also key players. Applications now cover robotics, EVs, 5G equipment, and consumer electronics.

Government support plays a big role. Policies encourage advanced manufacturing and automation, while clusters in Guangdong, Jiangsu, and Zhejiang help lower costs and boost efficiency. Foreign investment and joint ventures bring advanced technology into local plants.

Частина 2: Провідні компанії

Hikam Metal Tech

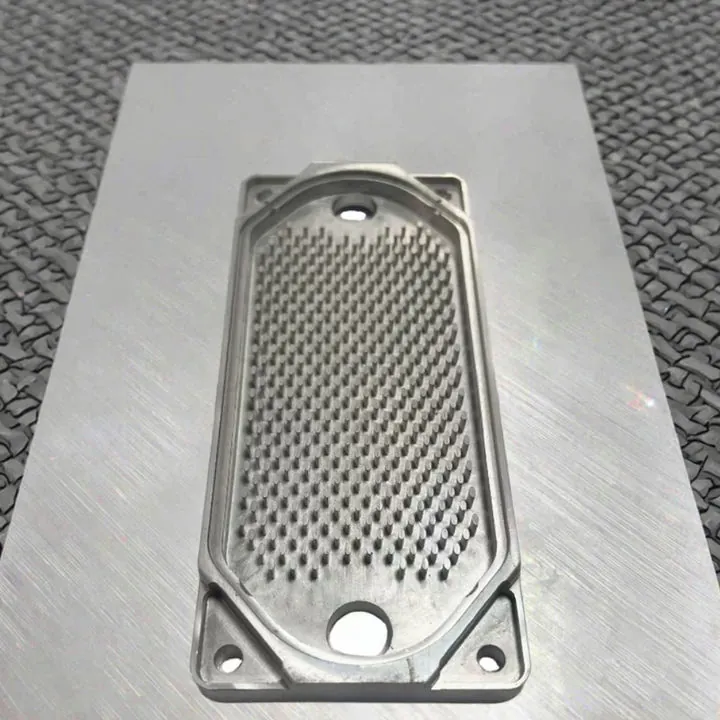

Hikam Metal Tech was founded in 2006 in Shenzhen. It started as a small workshop but now serves global clients in automotive and electronics. The company offers CNC turning, milling, and surface finishing services.

Its main industries include medical devices, EV components, and communication systems. The company is known for precision parts that meet ISO 9001 and ISO 13485 standards. Hikam invests in 5-axis machining and automation for faster production. Awards from local government highlight its export achievements.

Wayken Rapid

Wayken Rapid began in 1999 in Shenzhen as a prototyping service. Over time, it expanded into full CNC machining production. It offers milling, turning, and injection mold tooling.

The company serves automotive, aerospace, and industrial design firms. It focuses on prototype-to-production solutions, combining CNC machining with vacuum casting and low-volume molding. Its innovation lies in providing full product development cycles with high flexibility. Certifications include ISO 9001 and recognition from automotive suppliers.

3ERP

3ERP was established in 2008 in Dongguan. It started with rapid prototyping and now provides CNC machining, die casting, and injection molding.

The company’s clients include aerospace firms, automotive giants, and consumer electronics brands. Its strength lies in fast turnaround and international-standard quality control. It has ISO 9001 and AS9100 certifications, proving its capability in aerospace-grade machining. Awards from trade shows recognize its innovation in prototyping.

| Компанія | Засновано | Основні продукти | Галузі промисловості | Сертифікати |

|---|---|---|---|---|

| Hikam Metal Tech | 2006 | CNC turning, milling, finishing | Medical, EV, communication | ISO 9001, ISO 13485 |

| Wayken Rapid | 1999 | CNC machining, prototyping, tooling | Automotive, aerospace, design | ISO 9001 |

| 3ERP | 2008 | CNC machining, molding, casting | Aerospace, automotive, electronics | ISO 9001, AS9100 |

Частина 3: Виставки та галузеві заходи

CIMT (China International Machine Tool Show)

CIMT is one of the largest CNC-related exhibitions in Asia. It is held in Beijing every two years and attracts global manufacturers and buyers.

The event showcases CNC machining centers, automation, and smart manufacturing tools. Thousands of companies attend, from Japan, Germany, and the US. Highlights include new 5-axis machines and smart factory solutions.

CCMT (China CNC Machine Tool Fair)

CCMT is another major event, held in Shanghai. It focuses on CNC machining, robotics, and precision tools. It runs in alternating years with CIMT.

The fair attracts many domestic Chinese firms as well as international technology providers. It is known for live machine demonstrations and product launches. CCMT supports networking for suppliers and buyers across many industries.

| Подія | Дата | Місцезнаходження | Основні моменти |

|---|---|---|---|

| CIMT | Бієнале | Beijing | 5-axis machines, smart manufacturing |

| CCMT | Бієнале | Шанхай | CNC demos, robotics, precision tools |

Частина 4: Вплив глобальної торговельної політики

Global trade policies affect CNC machining heavily. Tariffs, export restrictions, and sanctions shape how Chinese firms operate. China faces pressure from the US and EU, but it also finds new markets in Southeast Asia and Africa.

Local substitution becomes more important as companies reduce dependence on foreign suppliers. CNC firms invest in local tooling, domestic metals, and AI-driven software to avoid risks. This shift strengthens the supply chain resilience inside China.

Competition remains global. While Chinese companies expand with cost advantages, they must meet higher quality and compliance standards to succeed abroad. Trade agreements like RCEP give Chinese CNC firms access to wider Asian markets, creating fresh opportunities.

Частина 5: Висновки

The CNC machining industry in China offers vast opportunities. With strong demand from automotive, aerospace, and electronics, the market will continue to expand. Government support and industrial clusters make China a global leader in CNC technology.

However, challenges remain. Firms must adapt to trade tensions, stricter certifications, and higher labor costs. Only companies that innovate and upgrade will stay competitive in this changing global environment.