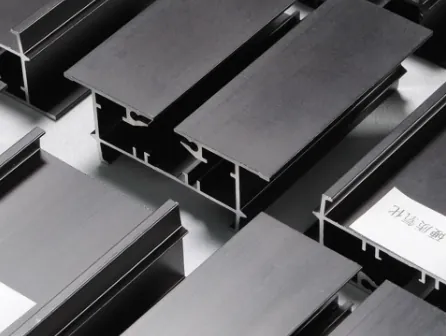

Стійкість алюмінієвого профілю до ударної сили?

Sudden impacts can crack frames, bend structures, and stop machines without warning. When designers underestimate impact force, even strong-looking aluminum profiles can fail earlier than expected.

Aluminum extrusions can resist impact force well when alloy choice, temper, geometry, and load path are designed together. Impact performance is not accidental. It is engineered.

Impact resistance is not only about strength numbers on a datasheet. It depends on how fast the load arrives, where it hits, and how the profile spreads that energy. The sections below explain how extruded profiles react to impact, which alloys behave better, how geometry changes shock response, and how dynamic testing validates real performance.

How do extruded profiles handle sudden impact loads?

Impact loads are different from slow static loads. A part that holds tons under slow compression can still crack when hit quickly. This difference matters in real products like machine guards, transport frames, and structural supports.

Extruded aluminum profiles handle sudden impact by deforming elastically first, then plastically if the load is high enough. Their ability to absorb energy depends on strain rate sensitivity, wall thickness, and how the load is distributed through the section.

What makes impact different from static load

Impact force is short in time but high in intensity. Instead of slowly spreading stress, it creates a stress wave that moves through the profile.

Key differences include:

- Higher local stress peaks

- Less time for stress redistribution

- Higher risk of crack initiation at corners or defects

Because of this, profiles that perform well in static tests may behave very differently under impact.

Elastic and plastic response during impact

When impact occurs, the profile responds in stages:

-

Elastic response

The aluminum stretches slightly. If the energy is low, it springs back with no damage. -

Plastic deformation

If energy exceeds the elastic limit, the profile bends or dents. This absorbs energy but leaves permanent shape change. -

Crack initiation or fracture

If local strain becomes too high, cracks can form, often at sharp corners, weld seams, or thin walls.

A good impact-resistant extrusion allows controlled plastic deformation before cracking.

Role of extrusion weld seams

Hollow extrusions contain longitudinal weld seams from metal flow joining in the die. Under impact, these seams can be either neutral or critical, depending on location.

- Seams placed in low-stress zones usually perform well.

- Seams aligned with tensile stress during impact can become crack initiation points.

Designers should consider seam position early, not after tooling is finished.

Real-world impact scenarios

Common impact cases for extruded profiles include:

- Forklift hits on machine frames

- Dropped components during installation

- Sudden stops in moving equipment

- Debris strikes in transport systems

Each case has a different load direction and speed. A profile optimized for one may fail in another.

Practical design habits

To improve impact handling:

- Avoid sharp internal corners.

- Use slightly thicker walls in impact zones.

- Spread load using brackets or plates instead of point contact.

Extruded aluminum profiles absorb impact energy through elastic and plastic deformation before cracking.Правда.

Under impact, aluminum first deforms elastically, then plastically, which helps absorb energy if geometry and alloy are suitable.

If an extrusion is strong under static load, it will always perform well under impact.Неправда.

Impact loads involve high strain rates and stress waves, so static strength alone does not guarantee good impact performance.

Which alloys provide better impact resistance?

All aluminum alloys are not equal under impact. Some are strong but brittle. Others are softer but absorb more energy before failure. Choosing the right alloy is one of the fastest ways to improve impact resistance.

Alloys with good ductility, moderate strength, and stable temper, such as 6061 and 6063 in suitable conditions, generally provide better impact resistance than very high-strength but low-ductility alloys.

Strength versus toughness

Impact resistance is closely tied to toughness, not just tensile strength.

- Висока міцність helps resist deformation.

- High ductility allows energy absorption.

- Toughness combines both.

An alloy with extreme strength but low elongation may crack suddenly under impact.

Common extrusion alloys and impact behavior

The table below compares typical extrusion alloys used in structural applications.

| Сплав | Typical temper | Relative strength | Пластичність | Impact resistance trend |

|---|---|---|---|---|

| 6063 | T5 / T6 | Середній | Високий | Good energy absorption |

| 6061 | T6 | Високий | Середній | Very good balance |

| 6005A | T6 | Високий | Середній | Good, stiffer response |

| 6082 | T6 | Дуже високий | Нижній | Strong but less forgiving |

| 7075 | T6 | Надзвичайно високий | Низький | Poor for impact unless redesigned |

Temper matters as much as alloy

The same alloy can behave very differently in different tempers.

- T5 tempers often have slightly lower strength but higher ductility.

- T6 tempers maximize strength but reduce elongation.

- Over-aged tempers can sometimes improve toughness at the cost of strength.

For impact-prone parts, slightly lower strength with higher elongation is often safer.

Temperature effects in real use

Impact resistance also changes with temperature:

- At low temperatures, aluminum becomes less ductile.

- At higher temperatures, strength drops but ductility rises.

Designers should consider worst-case service temperature when selecting alloy and temper.

Cost and availability trade-offs

High-toughness alloys may cost slightly more or require longer lead times. However, the cost of a field failure is almost always higher than the cost difference in material.

Alloys with higher ductility usually absorb more impact energy before cracking.Правда.

Higher ductility allows plastic deformation, which dissipates impact energy and delays fracture.

The strongest aluminum alloy always offers the best impact resistance.Неправда.

Very high-strength alloys often have low ductility, making them more brittle under sudden impact.

Can profile geometry improve shock absorption?

Geometry is often more powerful than material choice. Small changes in wall layout can double impact performance without changing alloy or temper.

Profile geometry improves shock absorption by controlling stiffness, spreading load paths, and allowing controlled deformation zones that dissipate impact energy instead of concentrating stress.

Stiff versus forgiving geometry

A very stiff profile transfers impact force quickly, which can raise peak stress. A slightly more flexible profile can lower peak stress by increasing deformation time.

This does not mean weak design. It means controlled compliance.

Key geometric features that help

Several features consistently improve impact behavior:

Rounded corners

Sharp corners concentrate stress. Rounded corners:

- Reduce crack initiation risk

- Improve metal flow during extrusion

- Improve fatigue and impact life

Multi-cell structures

Profiles with internal ribs or multiple chambers:

- Spread impact loads across more material

- Delay local buckling

- Improve energy absorption

Gradual wall thickness changes

Sudden thickness changes create stress risers. Smooth transitions help stress flow evenly.

Energy-absorbing zones

Some profiles intentionally include sacrificial zones:

- Thin walls that bend first

- External flanges that deform before the core

- Local crush zones near expected impact points

This approach is common in transport and safety-related designs.

Orientation of the profile

Impact resistance is directional.

- A profile may be strong in one axis and weak in another.

- Designers should align the strongest axis with expected impact direction.

Geometry comparison example

The table below shows how geometry changes impact response.

| Geometry feature | Impact effect | Typical result |

|---|---|---|

| Sharp external corners | Stress concentration | Early cracking |

| Rounded external corners | Stress reduction | Longer life |

| Single large cavity | Місцеве вигин | Sudden collapse |

| Multiple small cavities | Load sharing | Progressive deformation |

| Uniform thick walls | High stiffness | High peak stress |

| Variable walls | Controlled bending | Better energy absorption |

Manufacturing limits

Not every geometry is practical for extrusion. Extremely thin ribs or deep cavities may cause die wear or distortion. Good geometry balances performance and producibility.

Rounded corners and multi-cell profiles help spread impact loads and delay cracking.Правда.

These features reduce stress concentration and allow the profile to absorb energy through controlled deformation.

Profile geometry has little effect on impact resistance compared to alloy choice.Неправда.

Geometry strongly influences stiffness, load paths, and energy absorption, often more than alloy choice alone.

Are extrusions tested under dynamic load conditions?

Design assumptions are only as good as their validation. Impact resistance must be verified, not guessed.

Extruded aluminum profiles can be tested under dynamic load conditions using impact, drop, and fatigue-related methods that simulate real shock events and measure energy absorption, deformation, and failure modes.

Why dynamic testing matters

Static tests do not capture:

- Strain rate effects

- Stress wave behavior

- Real crack initiation patterns

Dynamic testing fills this gap.

Common dynamic and impact tests

Several methods are used, depending on application:

Drop weight impact tests

A known mass is dropped from a set height onto the profile. This test:

- Measures absorbed energy

- Shows deformation shape

- Reveals crack locations

Pendulum impact tests

Often used for material coupons, these tests compare relative toughness between alloys and tempers.

Full-scale component tests

For critical parts, entire assemblies are tested under simulated impact. This is costly but very informative.

Interpreting test results

Impact tests do not always give a single pass or fail number. Engineers look at:

- Maximum force

- Energy absorbed

- Deformation mode

- Crack initiation location

A profile that bends safely may be preferred over one that stays stiff but cracks.

Standards and internal validation

While there is no single universal impact standard for all extrusions, many industries use internal specifications based on known failure modes.

Suppliers often support:

- Prototype testing

- Section-level tests

- Iterative geometry changes based on results

Testing versus simulation

Finite element simulation helps predict impact behavior, but testing is still needed to confirm:

- Material batch variation

- Weld seam behavior

- Manufacturing tolerances

Simulation and testing work best together.

Dynamic impact testing reveals failure modes that static tests cannot show.Правда.

Impact tests capture strain rate effects and stress wave behavior that static loading does not represent.

If simulation results look good, physical impact testing is unnecessary.Неправда.

Simulation cannot fully account for real material variation, weld seams, and manufacturing effects, so testing remains important.

Висновок

Aluminum extrusion impact resistance comes from smart alloy choice, thoughtful geometry, and validation under real dynamic loads. When these factors work together, extruded profiles can absorb shock, protect systems, and fail in predictable, controlled ways.