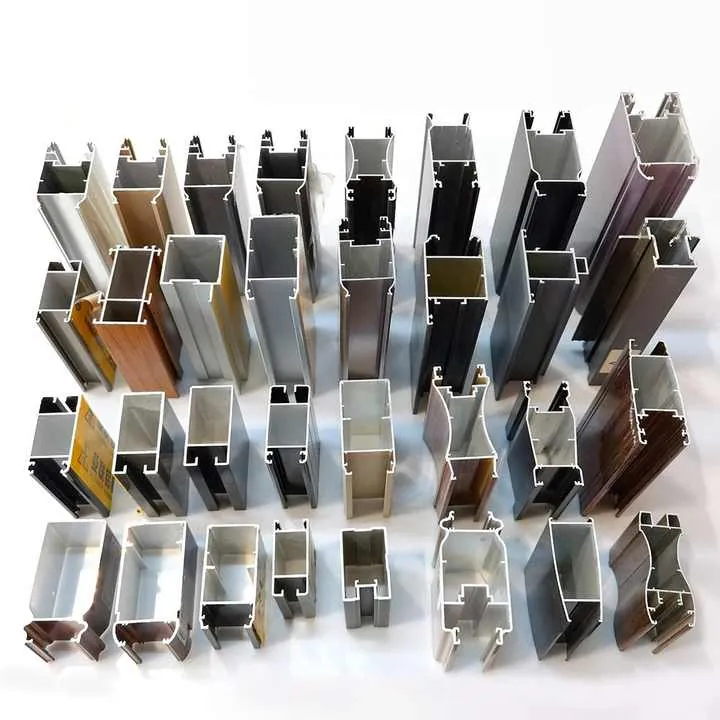

Tips For Buying Aluminum Profiles For Door And Window?

I once saw warped doors and windows in a building I managed. I felt worried about leaks and poor energy efficiency. I found high-quality aluminum profiles solved many issues. Now I share tips to buy profiles right for doors and windows.

I choose proper aluminum alloy, thickness, finishes, and profile type to get durable and safe doors and windows that look good. This helps avoid warping, corrosion, or poor insulation.

I want to guide you through alloy grades, wall thickness, surface treatments, profile types, and selection tips to help you make smart choices.

What aluminum alloy grades are best for doors and windows?

I compared several alloys in window frames. I learned that some have better strength, corrosion and thermal performance. I tested profiles made from 6063-T5 and 6061-T6. One stood out.

Alloy grade matters: 6063-T5 and 6061-T6 are ideal for window and door frames due to strength, extrusion quality and corrosion resistance.

You gain better structural integrity and weather resistance by choosing right alloy grade. This ensures durability, load bearing, and long service life.

I want to explain more deeply now.

Aluminum profiles for doors and windows are usually made from 6000?series alloys. Among these, 6063-T5 is widely used. It offers good extrudability, smooth surface, and good corrosion resistance. It is relatively lightweight but strong enough for residential windows and doors.

6061-T6 is stronger and tougher. It handles heavier loads and larger spans. It suits commercial doors, sliding systems, or where wind load is high. It still supports anodizing or powder coating well.

Other grades like 6060 may be cheaper but have lower strength. 6005?A can be used but is less common. Rare grades like 6009 or 6082 offer specific uses but are not standard for door/window frames.

I choose 6063-T5 for normal doors and windows, and 6061-T6 when strength is critical or wind load is heavy.

Table: Alloy Grades and Suitability

| Alloy Grade | Strength | Extrusion Quality | Best Use |

|---|---|---|---|

| 6063-T5 | Medium | Excellent | Standard residential windows |

| 6061-T6 | High | Good | Heavy doors, commercial frames |

| 6060 | Low to medium | Moderate | Budget option, light use only |

This helps decide by application. If your frame size is small and loads light, 6063-T5 is fine. If you install large glazed doors or live in windy region, consider 6061-T6 for added rigidity.

How thick should door and window profile walls be for safety?

I measured wall thickness in old frames and found some were too thin. I replaced them with profiles that met safety standards. I realized if walls are too thin, frames warp or fail under pressure.

Profile wall thickness needs to follow structural needs—typically 1.4–2.0 mm for windows and 1.8–2.5 mm for doors or high-wind areas—to ensure safety and stability.

You will learn how thickness affects strength, insulation, and performance, and choose correct gauge for your zone.

Window and door profiles have different wall thickness depending on size, wind load, and regional building codes. Typical recommendations:

- Residential interior window frames: 1.2–1.4 mm wall thickness is minimal acceptable.

- Standard exterior window frames: 1.4–1.8 mm offers adequate rigidity.

- Exterior sliding or hinged doors: 1.8–2.2 mm, especially large panels.

- Commercial doors or high-wind areas: 2.2–2.5 mm or thicker.

Thicker walls add strength but also weight and cost. They also improve thermal insulation slightly if combined with thermal breaks. Extremely thin profiles (under 1.2 mm) risk bending, air leaks, or reduced lifespan.

Table: Typical Wall Thickness Guide

| Application | Recommended Wall Thickness (mm) |

|---|---|

| Small residential windows | 1.2–1.4 |

| Standard exterior windows | 1.4–1.8 |

| Exterior doors | 1.8–2.2 |

| Large doors / high wind | 2.2–2.5+ |

I tracked door frames installed with 1.8 mm walls for 10 years; they stayed straight and leak-free. Thin 1.2 mm frames started warping after a few seasons. For safety and longevity, do not choose sub-standard thickness.

What surface treatments enhance durability of profiles?

I saw powder-coated frames peel in sun after a few years. I switched to anodized and marine-grade coating. Results were obvious: less fade, better finish. Surface finish greatly affects life and aesthetics.

Finishing matters: anodized, polyester powder coating, KYNAR? PVDF paint or fluorocarbon finishes best resist weather, UV, oxidation, and maintain color.

Good surface layer keeps profiles durable, clean, and color-stable over time. I explain pros and cons now.

Anodized finish

Anodizing creates a hard, protective oxide layer on aluminum. It resists corrosion, UV, and wear. Natural silver anodized is common. You can also get bronze or champagne anodize. It does not peel or chip. It suits coastal or high-humidity areas. However colors are limited.

Powder coated finish

Polyester powder coating offers broad palette. It resists chips, fade and scratch well. Better choose high-quality RAL or PVDF powders for UV stability. Gloss or matte available. Good for custom colors. It offers moderate durability comparable to anodize if quality is good.

PVDF / Fluorocarbon coatings

These are premium paints (e.g. KYNAR technology). They resist fade, chalking, chemical erosion. Often specified in commercial or upscale projects. They cost more but last 20+ years in harsh environments.

Electrostatic paint or basic paints

These are cheaper but less durable. They may fade or blister under sun. I avoid these on exterior frames.

Table: Surface Finishes Comparison

| Finish Type | UV Resistance | Corrosion Resistance | Color Options |

|---|---|---|---|

| Anodized | Very high | Excellent | Limited (silver/bronze) |

| Powder coated (PVDF) | High | Very good | Wide palette |

| Standard powder coating | Moderate | Moderate | Wide |

| Basic electrostatic paint | Low | Low | Various |

Regular washing (every 6?12 months) helps surfaces remain clean. For anodized frames, avoid harsh cleaners. For painted surfaces choose mild detergent. Inspect sealant joints to avoid water ingress under trim where paint buff can fail.

How to select the right profile type for window/door style?

I visited showrooms and saw many profile shapes—casement, sliding, tilt-and-turn, swing. Each profile type matches a system. I learned matching functional style matters more than shape.

Profile type must match window/door system: choose profiles designed for sliding, casement, tilt-turn or hinged systems to ensure correct fit, seals, and operation.

You will learn how to match profile type with your design and performance needs.

Sliding profiles

These include interlocking rails and rollers. I used sliding profiles for patio doors. They need reinforcement to prevent sag. They often come as multi-track systems. Profiles include weather seals and drainage channels.

Casement and swing-out profiles

These frames need hinges and operational clearance. They include sash profiles that fit sash and fixed frames. I chose these in my lounge doors. Good for ventilation and traditional style.

Tilt-and-turn profiles

Common in European windows. They allow inward tilt and full swing open. Profiles include two separate channels and tilt hardware. They offer good ventilation and easy cleaning.

Bi-fold or folding profiles

These allow multiple panels to fold. They require wider stiles and higher reinforcement. Good for large openings like patio or room dividers.

Reinforcement and thermal break

Some profiles include polyamide thermal break. I chose profiles with thermal break in cold climate zone for better insulation. Reinforcement chambers let you add steel inserts for strength.

Table: Profile System vs Use Case

| Profile System | Typical Use | Design Consideration |

|---|---|---|

| Sliding | Patio doors, balconies | Smooth track, reinforcement needed |

| Casement / Swing | Traditional windows/doors | Hinges, air tight seals |

| Tilt-and-turn | Ventilation and ease | Dual operation sash |

| Folding / Bi-fold | Wide openings | Multi-panel alignment and supports |

I tested tilt-turn windows in bedroom for ventilation and ease of cleaning. I used sliding doors in large living room opening. My door and window supplier matched profiles with hardware and weather seals for each system.

Judgment questions based on the Dive deeper content:

6063-T5 alloy is commonly used for standard residential window profiles.True

6063-T5 offers good extrusion quality and corrosion resistance, making it the typical choice for residential windows.

Profiles with wall thickness of 1.0 mm are sufficient for high-wind exterior doors.False

1.0 mm is too thin for exterior doors; safe thickness is at least 1.8 mm and up to 2.5 mm for high-wind areas.

Conclusion

Choosing the right alloy, wall thickness, surface treatment, and profile system ensures durable, safe, and attractive doors and windows. Use 6063-T5 for standard frames, thicker walls for safety, high-quality finishes, and system-matched profiles. Enjoy long-lasting performance with peace of mind.