Slot Aluminum Extrusion Profile for Industrial Equipment?

You want a strong, flexible frame system for your machines—but bolts and steel frames waste time and money.

Slot aluminum profiles offer modular strength and fast assembly for all types of industrial equipment frames.

Read on to see why these profiles are changing industrial design.

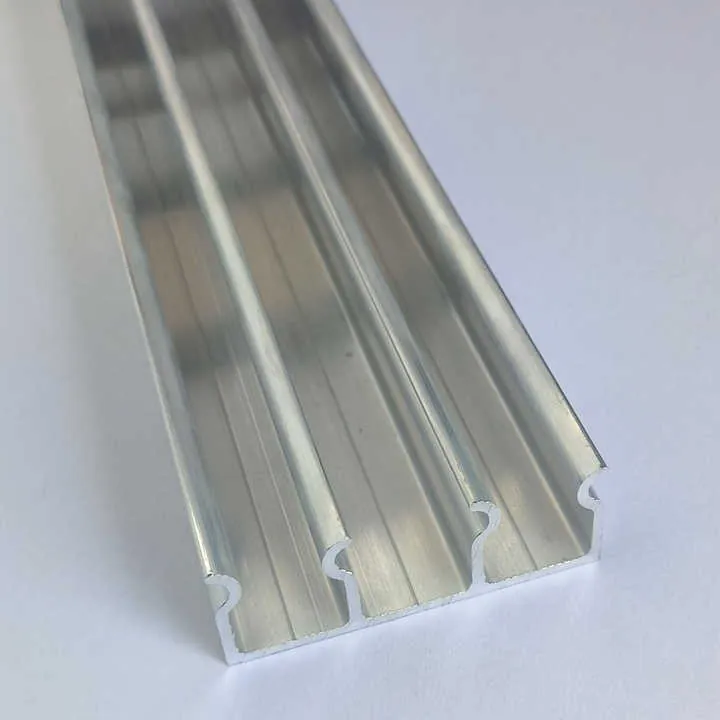

What is a slot aluminum extrusion profile?

You’ve seen the silver frames on machines but don’t know the name.

Slot aluminum profiles are modular metal bars with grooves that allow bolt-free assembly, used to build strong industrial structures.

They look simple, but they can do a lot more.

How slot profiles are made

Slot profiles are made by extruding aluminum through a mold. Most are from 6063-T5 alloy. They have grooves along the length. These grooves let you slide in bolts, nuts, brackets, and plates—without drilling.

Why use aluminum?

- Lightweight: Easier to move and install than steel.

- Strong enough: Handles most machine loads.

- No rust: No extra coating needed.

- Modular: You can cut and join as needed.

- Reusable: Easy to take apart and rebuild.

Common cross-section shapes

| Shape Type | Description | Use Case |

|---|---|---|

| T-slot | Standard groove shape | Most machines and conveyors |

| V-slot | Rounded V-groove | Precision rail movement systems |

| L-slot | 2-sided groove | Corner frames or space savers |

| C-slot | Narrow groove with locking channel | Light-duty mounts and panels |

I use T-slot frames in most factory automation projects. They’re easy to adjust when a customer changes their mind mid-build.

Slot aluminum profiles allow bolt-free assembly using T-nuts and brackets.True

T-slots let fasteners slide in grooves without drilling, enabling modular construction.

Slot aluminum profiles are heavier than welded steel frames.False

Aluminum is lighter than steel, making it easier to transport and handle during installation.

How are slot profiles used in industrial machinery?

You see slot frames everywhere but wonder what they do.

Slot aluminum profiles are used to build machine guards, workstations, frames, enclosures, carts, and robotics mounts.

Here’s how industries apply them daily.

Major use cases

1. Machine framing

Slot profiles are used to build the entire outer frame of industrial machines. This includes CNC machines, printing presses, laser cutters, and 3D printers. No welding needed.

2. Enclosures and guards

Aluminum profiles are perfect for safety barriers. You can mount plastic panels, wire mesh, or glass between the slots. They keep operators safe without blocking visibility.

3. Workstations and benches

Adjustable tables, shelves, and tool racks are built with these profiles. You can add monitor arms, keyboard trays, lights, and wheels—all connected with slot brackets.

4. Automated systems and robotics

Robotic arms, conveyors, and control panels often mount to slot frames. They allow precise adjustment and easy upgrades over time.

5. Transport carts

Rolling carts for tools, components, or products can be built with lightweight aluminum profiles. Slots allow height adjustments for shelves and fixtures.

| Application | Description | Benefit |

|---|---|---|

| Machine Frame | Core support for machines | Strong, modular, flexible |

| Safety Guard | Protective barrier panels | Easy to install and remove |

| Workstation | Adjustable desks or stations | Ergonomic, expandable |

| Robot Mount | Base for robot tools | Precision positioning |

| Transport Cart | Movable shelf units | Lightweight, strong, mobile |

I once reconfigured a robot station overnight using slot profiles. That would have taken a week with steel welding.

Slot profiles are only used for light-duty enclosures.False

Slot aluminum profiles are also used in heavy-duty machine frames, conveyor systems, and robotic setups.

Slot profiles are often used for adjustable workbenches.True

Slot aluminum allows you to easily mount and reposition shelves, arms, and brackets on workstations.

What sizes and slot configurations are available?

You’ve decided to try slot profiles but don’t know which size.

Slot profiles come in multiple series like 20mm, 30mm, 40mm, and 45mm, with 6mm to 10mm grooves for matching fasteners.

Let’s decode the system.

Standard sizes and naming

Slot systems are grouped by base size. For example, “40×40” means the profile is 40?mm wide and 40?mm tall.

Each size group fits a specific groove size. You need matching T-nuts and connectors.

| Profile Series | Width x Height (mm) | Groove Size | Used For |

|---|---|---|---|

| 20 Series | 20×20, 20×40 | 6mm | Small assemblies, models |

| 30 Series | 30×30, 30×60 | 8mm | Light machinery, DIY systems |

| 40 Series | 40×40, 40×80 | 8mm | Standard industrial frames |

| 45 Series | 45×45, 45×90 | 10mm | Heavy equipment, automation |

Larger profiles support heavier loads and offer more stability for tall structures.

Slot orientation

- 4-slot: A square profile with one groove on each side.

- 3-slot: Missing one side—used near walls.

- 2-slot: For corners or compact builds.

- 1-slot: For single rail tracks or basic mounts.

You can also get:

- Closed slot profiles: To hide slots for cleaner look.

- Reinforced core profiles: Extra thickness for load-bearing use.

I always use 45 Series for conveyors and robot cells. For electronics enclosures, 30 Series is more than enough.

40x40 slot profiles typically use 8mm T-slot fasteners.True

40x40 and 30x30 profiles are designed with 8mm wide slots for standard hardware.

20 Series slot profiles are stronger than 45 Series.False

20 Series profiles are smaller and designed for light use, while 45 Series handles heavier loads.

How to install and maintain slot aluminum profiles in equipment?

You want to use slot profiles but worry about tools and upkeep.

Slot aluminum profiles install using basic tools like Allen keys, and require little to no maintenance besides occasional tightening.

Here’s how to do it right the first time.

Tools you need

- Allen wrenches

- T-nuts and brackets

- Rubber mallet (for inserts)

- Tape measure

- Square

- Marker or scriber

No welding or cutting torches. You can build almost everything with hand tools.

Steps to install

-

Plan your build

- Use CAD or sketch a drawing.

- Note sizes, types, and connectors.

-

Cut and prep

- Cut profiles to size with a miter saw.

- Deburr ends and clean surfaces.

-

Insert T-nuts and brackets

- Slide nuts into slots before adding ends.

- Attach corner brackets or joining plates.

-

Align and tighten

- Use square to check angles.

- Tighten bolts with Allen wrench.

-

Mount components

- Add shelves, panels, wheels, or machines.

- Drill and mount only if needed.

Maintenance tips

- Check tightness every 6 months.

- Clean dust from slots and moving parts.

- Lubricate joints if used with motion systems.

- Replace worn T-nuts or bolts as needed.

| Task | Frequency | Tools Needed |

|---|---|---|

| Bolt check | 2x/year | Allen wrench |

| Cleaning slots | Monthly | Cloth, brush |

| Replacing parts | As needed | Allen wrench, new parts |

| Realignment check | Yearly | Square, level |

My team once rebuilt a full control panel frame onsite in 3 hours. No welders, just slot frames and Allen keys.

Slot aluminum profiles require welding for proper installation.False

Slot systems are designed to be assembled with brackets and T-nuts, without welding.

Routine bolt tightening extends the life of a slot profile frame.True

Loose bolts can lead to vibration and misalignment; checking tightness helps ensure long-term reliability.

Conclusion

Slot aluminum extrusion profiles are the flexible backbone of modern industrial equipment. With modular assembly, easy maintenance, and strong load performance, they cut time and cost across machines, workbenches, and automation. Choose the right size and you’ll build smarter, faster, and better.