Обработка с ЧПУ Сербия: производители и промышленный справочник

Часть 1: Размер и рост рынка

Serbia has become one of Southeast Europe’s most promising hubs for precision manufacturing. Over the last decade, Обработка на станках с ЧПУ has grown rapidly thanks to foreign investment, industrial automation, and skilled technical labor. The country’s strategic position-connecting Western Europe, the Balkans, and Central Asia-makes it ideal for export-oriented manufacturing and engineering services.

Serbia’s industrial sector includes automotive, aerospace, energy, defense, and consumer goods production. CNC machining serves as the backbone for these industries, offering high-quality components, molds, and assemblies. Workshops across Belgrade, Novi Sad, Kragujevac, and Ni? operate modern CNC mills, lathes, and multi-axis machining centers. Local suppliers now serve both domestic and international clients, especially in Germany, Italy, and neighboring EU markets.

The Serbian government supports industrial modernization through programs that encourage technology transfer, vocational training, and export promotion. Coupled with affordable labor and expanding technical universities, these factors position Serbia as an emerging precision engineering center in the Balkans.

Часть 2: Ведущие компании

Serbia’s CNC machining landscape includes both long-established factories and modern startups that focus on quality, flexibility, and customer-specific solutions. Below are notable examples of machining service providers that represent the country’s industrial capability.

TPR Serbia Precision Engineering

Свяжитесь сейчас

TPR Serbia is a Belgrade-based CNC machining and metal fabrication company serving the automotive, industrial, and aerospace sectors.

They specialize in high-precision parts, assemblies, and fixtures using 3-, 4-, and 5-axis machining centers. The company’s strengths include CNC milling, turning, grinding, and surface treatment. TPR Serbia’s commitment to quality is reinforced by strict inspection protocols and modern CAD/CAM systems. Their core advantage lies in high repeatability and export-grade quality, which has made them a trusted partner for clients across Europe.

Inmold Plast d.o.o.

Свяжитесь сейчас

Inmold Plast, located in Po?ega, is one of Serbia’s leading mold-making and CNC machining companies.

Founded in the early 2000s, the company provides tool design, mold manufacturing, and automation systems. Its CNC operations include milling, EDM (electrical discharge machining), and finishing for high-precision plastic injection molds. Inmold Plast serves customers in automotive, electronics, and packaging industries. Their facility integrates design and manufacturing, ensuring fast turnaround and full control from concept to production.

Knez Metal d.o.o.

Свяжитесь сейчас

Knez Metal, based in Novi Sad, focuses on metal machining, laser cutting, and welding.

The company runs CNC milling and turning machines to produce complex components for industrial machinery, automation systems, and construction equipment. Their workshop supports both serial production and custom part fabrication. Knez Metal’s flexibility and use of modern European machine tools allow it to deliver consistent precision while maintaining competitive costs.

Sigma Technology Serbia

Свяжитесь сейчас

Sigma Technology provides CNC machining, mechatronics, and engineering design services to the manufacturing and robotics sectors.

Located in Kragujevac, the firm offers end-to-end solutions including design, simulation, machining, and assembly. Sigma’s CNC division produces aluminum, steel, and polymer components for automation systems and electronic devices. Their advantage lies in combining digital manufacturing technology with engineering consultancy, giving clients complete control from prototype to production.

Metalopromet AD

Свяжитесь сейчас

Metalopromet AD, based in Kraljevo, is one of Serbia’s older industrial companies that has successfully modernized.

It provides heavy-duty machining, CNC milling, and turning for steel structures, industrial machinery, and energy systems. The company integrates traditional metalworking experience with CNC upgrades to meet modern tolerance and quality standards. Its focus on large-format machining makes it ideal for construction, hydroelectric, and heavy engineering projects.

| Компания | Основано | Основные услуги | Обслуживаемые отрасли | Сильные стороны |

|---|---|---|---|---|

| TPR Serbia Precision Engineering | 2010s | Фрезерование, точение, шлифование с ЧПУ | Automotive, aerospace, machinery | High precision, export capability |

| Inmold Plast d.o.o. | 2000s | Mold making, CNC machining, automation | Automotive, electronics, packaging | Integrated design-to-production |

| Knez Metal d.o.o. | 2010s | CNC machining, laser cutting, welding | Construction, industry, automation | Flexibility, modern equipment |

| Sigma Technology Serbia | 2010s | CNC machining, mechatronics, design | Robotics, electronics | Combined design and production |

| Metalopromet AD | 1980s | Heavy machining, fabrication | Energy, hydro, industrial | Large part machining capacity |

Часть 3: Торговые выставки и отраслевые мероприятия

International Technical Fair (Belgrade)

The Belgrade International Technical Fair is Serbia’s leading event for machinery, metalworking, and industrial technology.

CNC manufacturers and suppliers participate to display machines, tools, and precision components. Exhibitors range from local machining companies to global brands. The fair also features automation, additive manufacturing, and engineering innovation, attracting thousands of visitors from the Balkans and Central Europe.

SEE Industry Expo (Southeast Europe)

This trade show gathers industrial technology providers from Serbia, Croatia, Slovenia, and other regional markets.

CNC machining companies use it to network, explore export opportunities, and showcase their engineering capabilities. The event emphasizes sustainable manufacturing, digitalization, and new technologies for smart factories.

| Событие | Частота | Расположение | Основные моменты |

|---|---|---|---|

| Международная техническая ярмарка | Ежегодно | Belgrade | CNC machines, automation, tooling |

| SEE Industry Expo | Ежегодно / раз в два года | Regional / Serbia | Smart manufacturing, digitalization |

Часть 4: Влияние глобальной торговой политики

Serbia’s CNC machining industry benefits from its strategic trade relationships.

Although not an EU member, Serbia has numerous free-trade agreements with the European Union, the Eurasian Economic Union, Turkey, and CEFTA countries. These agreements make Serbia a cost-effective export base for European manufacturing. CNC parts and assemblies produced in Serbia can be exported to major markets with minimal tariffs, attracting international clients.

However, dependence on imported tooling, machine parts, and raw materials still affects pricing stability. Currency fluctuations and logistics costs can raise production expenses. Workshops have responded by diversifying suppliers and developing in-house tooling capabilities to reduce import dependency.

Energy costs, infrastructure quality, and skilled labor availability are additional factors influencing the machining landscape. Serbia’s reliable power grid and investment in industrial zones have improved operating conditions. Technical education remains strong, supported by engineering faculties in Novi Sad, Belgrade, and Ni?, which train students in CAD/CAM programming and machine operations.

International partnerships are key drivers of modernization. Joint ventures between Serbian workshops and foreign manufacturers help transfer technology and create local supply chains. This trend has accelerated Serbia’s transition from manual production to high-precision, export-oriented CNC machining.

Environmental and sustainability policies are also shaping the industry. Many workshops adopt energy-efficient CNC systems and recycling programs to meet European client standards. Compliance with ISO certifications and lean manufacturing practices is becoming common, ensuring competitiveness in global supply chains.

Часть 5: Заключение

CNC machining in Serbia represents the strength and adaptability of a nation bridging Eastern and Western industrial practices. Companies such as TPR Serbia, Inmold Plast, Knez Metal, Sigma Technology, и Metalopromet AD demonstrate that Serbian manufacturers can match international standards in precision, quality, and reliability.

The country’s growing network of industrial parks, technical schools, and supportive trade policies provide a solid foundation for expansion. As global manufacturing shifts toward nearshoring and regionalization, Serbia’s central location and skilled workforce give it a distinct competitive edge in the European supply chain.

The next decade will likely see continued investment in automation, robotics, and digital manufacturing. With sustained modernization, CNC machining in Serbia can evolve from regional service provision to a leading precision manufacturing hub in Southeast Europe-supplying everything from automotive molds to aerospace components.

The combination of tradition, technology, and technical expertise ensures Serbia’s CNC sector is well-positioned to contribute to the global precision engineering economy while driving domestic industrial growth.

Рекомендуемое чтение:

- Обработка с ЧПУ Монголия: Производители и промышленный справочник

- Обработка с ЧПУ в Джибути: производители и промышленный справочник

- Обработка с ЧПУ Камерун: Производители и промышленный справочник

- Обработка с ЧПУ Гондурас: Производители и промышленный справочник

- Обработка с ЧПУ Панама: Справочник производителей и промышленности

- Обработка с ЧПУ Сан-Марино: Справочник производителей и промышленности

- Обработка с ЧПУ Исландия: Путеводитель по производителям и промышленности

- Обработка с ЧПУ Уганда: Справочник производителей и промышленности

Какова прочность алюминия 7075 по сравнению со сталью?

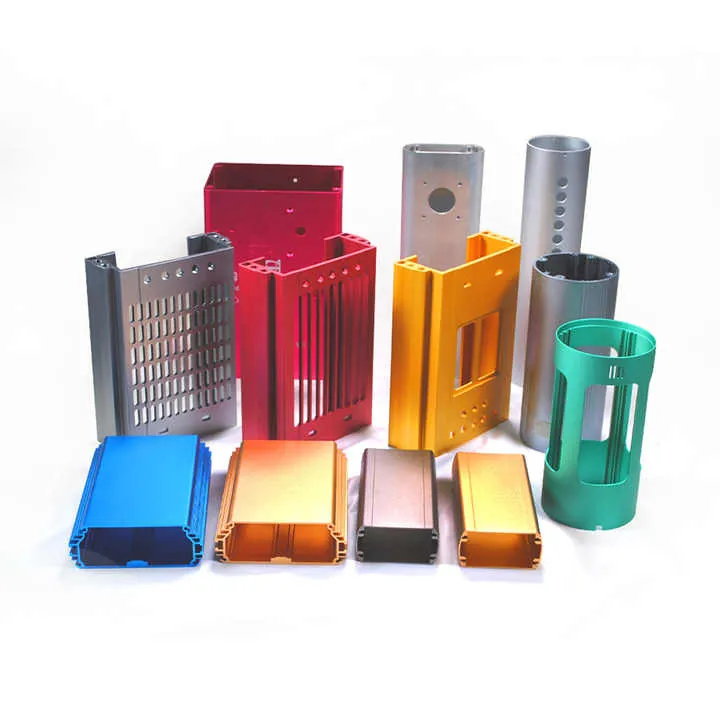

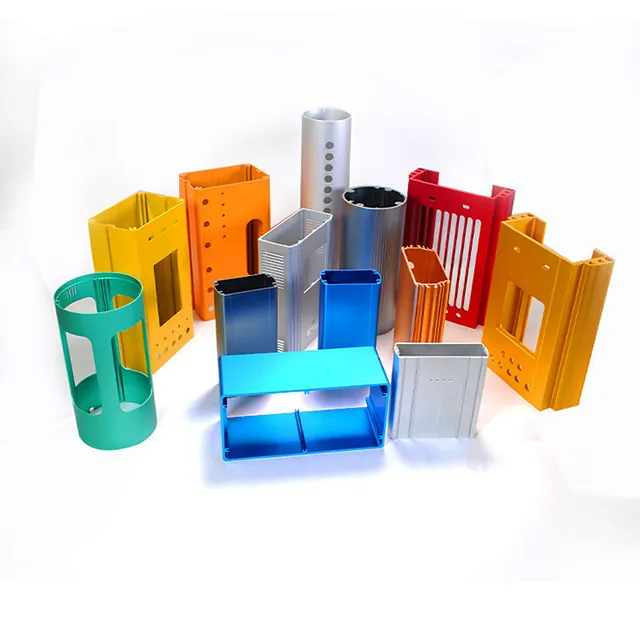

Экструзионная алюминиевая рама

H-образный алюминиевый профиль

6063 6061Алюминиевые экструзии для дверных коробок