CNC Machining Germany: Manufacturers & Industry Guide

Market Size and Growth

Germany has a long history in precision engineering, and CNC machining plays a central role in this tradition. The industry has grown with the rise of automation and demand for high-accuracy parts in automotive, aerospace, and medical sectors. The German CNC market is strong due to its skilled workforce and global reputation for quality.

The market size in Germany reflects its industrial strength. Small and medium firms work alongside global corporations, creating a diverse ecosystem. Many of these firms export parts and machines worldwide, making Germany a key global hub. Applications range from custom components to large-scale production.

Policies also shape this industry. German and EU support for advanced manufacturing, digitalization, and green technology encourage investment. Industrial clusters in Bavaria, Baden-Württemberg, and North Rhine-Westphalia host major CNC firms and research centers. This creates innovation and collaboration across the supply chain.

Leading Companies

DMG MORI

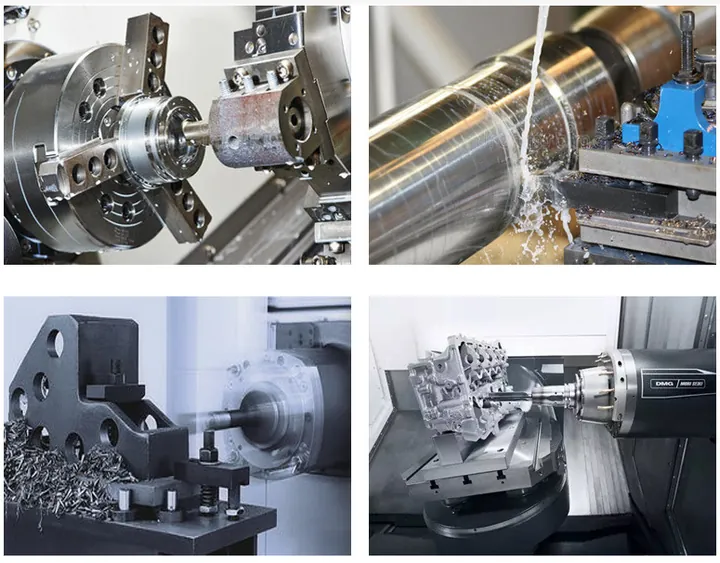

DMG MORI is one of the best-known CNC machine tool manufacturers in Germany. The company was formed from a merger of German and Japanese machine builders, and it operates from several German cities. It is recognized for advanced milling, turning, and automation solutions.

The company provides machines for automotive, aerospace, medical, and toolmaking industries. Its services include software integration and smart factory systems. DMG MORI has developed digital platforms that link machines with production lines, making it a leader in Industry 4.0 solutions. Its products are certified to high international standards.

HELLER

HELLER was founded in Nürtingen in 1894 and has grown into a major CNC machine manufacturer. It is known for its strong expertise in 4- and 5-axis machining centers. The company has a strong customer base in the automotive and aerospace industries.

HELLER focuses on flexible machining solutions, from small batch to high-volume production. It offers services like process optimization and training. The company invests heavily in energy-efficient machine concepts and advanced spindle technologies. It has won awards for innovation and sustainable engineering practices.

CHIRON Group

CHIRON Group, based in Tuttlingen, specializes in vertical machining centers and turnkey solutions. Founded in 1921, it has built a strong reputation for precision and speed. The company is a major supplier to medical, aerospace, and precision tool industries.

CHIRON delivers customized machines and automation systems for fast and precise part production. It supports digital monitoring tools to help customers improve efficiency. Its technical highlights include high-speed cutting systems and modular designs. CHIRON has received certifications for quality and safety in international markets.

| Company | Основано | Core Products | Промышленность | Сертификаты |

|---|---|---|---|---|

| DMG MORI | Merger of German & Japanese firms | CNC milling, turning, automation | Automotive, aerospace, medical | ISO & global quality certifications |

| HELLER | 1894 | 4- and 5-axis machining centers | Автомобильная промышленность, аэрокосмическая промышленность | Innovation and sustainability awards |

| CHIRON Group | 1921 | Vertical machining centers, turnkey solutions | Medical, aerospace, precision tools | International quality certifications |

Торговые выставки и отраслевые мероприятия

EMO Hannover

EMO Hannover is the largest metalworking trade show in the world, held every two years in Hanover, Germany. It attracts thousands of exhibitors and visitors from across the globe. The event is a key stage for CNC machine builders to show their newest technologies.

The exhibition covers CNC machines, automation, robotics, and software. Visitors include industry leaders, suppliers, and engineers. EMO Hannover is known for its scale and the launch of new solutions that later set global standards.

AMB Stuttgart

AMB Stuttgart is another important trade fair for metalworking, held every two years in Baden-Württemberg. It focuses on machining and precision engineering. The fair gathers suppliers, manufacturers, and research institutions.

The event highlights new CNC machines, tools, and digital factory concepts. It also includes live demonstrations and workshops. AMB Stuttgart is an important meeting point for companies from southern Germany, where many CNC firms are based.

| Событие | Дата | Расположение | Highlights |

|---|---|---|---|

| EMO Hannover | Каждые 2 года | Hanover, Germany | World’s largest CNC and metalworking fair |

| AMB Stuttgart | Каждые 2 года | Stuttgart, Germany | Focus on machining, tools, and innovation |

Impact of Global Trade Policies

Global trade rules have a strong impact on CNC machining in Germany. Exports are central to the industry, and any restrictions or tariffs affect business. Sanctions and trade tensions can slow down orders from certain regions.

Germany also faces supply chain risks from global disruptions. Firms are now looking at local sourcing or European partners to reduce dependence on imports. This change supports EU goals for resilience but may raise costs for smaller firms.

International competition is both a challenge and an opportunity. German companies compete with Asian and American manufacturers but remain attractive due to precision and reliability. Free trade agreements and EU policies create new openings in emerging markets.

Заключение

The CNC machining industry in Germany has strong roots and a bright future. Its global reputation for quality and innovation ensures steady growth. New technologies and industrial policies will continue to support progress in this field.

At the same time, challenges remain. Global trade shifts, supply chain risks, and strong competition may test German firms. The industry must balance tradition with innovation to stay at the top of global manufacturing.