Коэффициент теплового расширения алюминиевого экструзионного профиля?

Тепловое расширение часто скрывается до тех пор, пока не станет причиной трещин, шума или смещения. Многие покупатели замечают его только после установки. Эта тема заслуживает четких ответов до появления проблем.

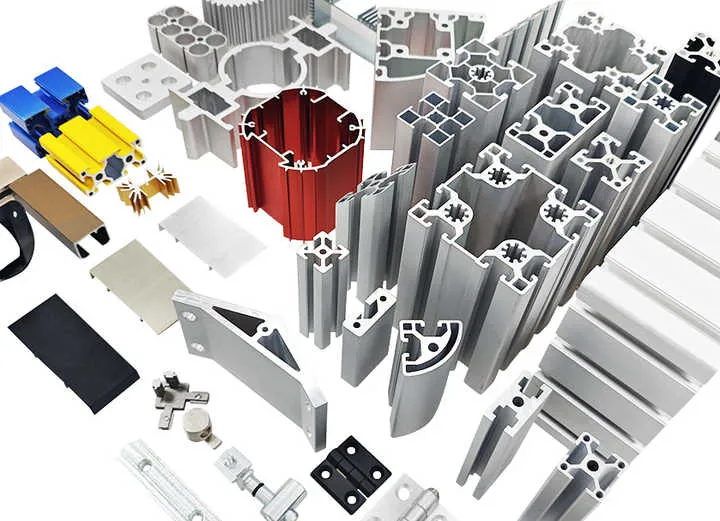

Скорость теплового расширения алюминиевых экструзий объясняет, насколько изменяется длина профиля при изменении температуры. Понимание этого показателя помогает предотвратить деформацию, напряжение и разрушение в реальных проектах.

Этот предмет связывает материаловедение с реальным строительством и промышленным использованием. Знать основы недостаточно. Важно то, как это поведение проявляется в повседневном производстве и крупных конструкциях.

Какова средняя скорость теплового расширения экструзии?

Тепловые движения могут повредить соединения и узлы, если их игнорировать. Многие проекты терпят неудачу, потому что проектировщики полагают, что металл остается стабильным. Алюминий ведет себя иначе.

Средняя скорость теплового расширения алюминиевых экструзий составляет около 23 x 10^-6 на градус Цельсия. Это означает, что один метр алюминия увеличивается примерно на 0,023 мм на каждый 1 C повышения температуры.

Эта величина кажется небольшой, но при большой длине и широком диапазоне температур эффект становится значительным. В экструзионных проектах профили часто достигают нескольких метров. При использовании на открытом воздухе температура может колебаться более чем на 50 C. Это создает видимые и ощутимые движения.

Почему алюминий расширяется сильнее, чем сталь

Атомы алюминия сильнее перемещаются при нагревании. Кристаллическая структура позволяет изменять расстояние между атомами по сравнению со сталью. Поэтому алюминий сильнее реагирует на тепло, хотя и быстро остывает.

На практике это свойство несет в себе как преимущества, так и риски. Алюминий устойчив к растрескиванию при тепловом ударе. Но ему необходимо пространство для движения.

Типичные значения расширения в реальных проектах

Ниже приведена простая таблица, используемая на ранних стадиях проектирования. Она помогает покупателям оценить перемещение до окончательных чертежей.

| Длина экструзии | Изменение температуры | Общее расширение |

|---|---|---|

| 1 метр | 30 C | 0,69 мм |

| 3 метра | 40 C | 2,76 мм |

| 6 метров | 50 C | 6,90 мм |

Эти цифры являются усредненными. Обработка поверхности, сплав и напряженное состояние могут несколько изменить результат. Тем не менее, эта таблица позволяет избежать распространенных ошибок.

Почему средние значения - это только отправная точка

Средние ставки не заменяют инженерных проверок. Они помогают принимать решения на ранних этапах. В окончательных конструкциях необходимы припуски, скользящие соединения или гибкие соединители.

На экструзионных заводах эта скорость также влияет на допуск на резку. Профили, нарезанные при высокой температуре, могут сжиматься после охлаждения. Хорошие мастерские планируют это в процессе производства.

Алюминиевые экструзии заметно расширяются при изменении температуры, особенно длинные профили.Правда

Скорость расширения алюминия вызывает измеримые изменения длины при изменении температуры, и этот эффект растет с увеличением длины профиля.

В наружных конструкциях тепловым расширением алюминиевых экструзий обычно можно пренебречь.Ложь

Наружные конструкции часто подвержены большим перепадам температур, поэтому расширение является критическим фактором при проектировании.

Как состав сплава влияет на скорость расширения?

Многие покупатели полагают, что весь алюминий ведет себя одинаково. Это не так. Выбор сплава изменяет тепловое поведение небольшими, но важными способами.

Состав сплава немного изменяет скорость теплового расширения, но разница обычно находится в узком диапазоне для распространенных экструзионных сплавов, таких как 6063 и 6061.

Основным металлом является алюминий. Легирующие элементы регулируют прочность, твердость и коррозионную стойкость. Они также влияют на расстояние между атомами.

Сравнение распространенных экструзионных сплавов

Широко используются 6063 и 6061. Оба относятся к семейству алюминиево-магниево-кремниевых. Их скорости расширения близки, но не идентичны.

| Сплав | Типичная скорость расширения (на C) | Общее использование |

|---|---|---|

| 6063 | ~23.5 x 10^-6 | Архитектурные профили |

| 6061 | ~23.1 x 10^-6 | Структурные и промышленные |

На бумаге разница выглядит небольшой. В 10-метровой конструкции с большими тепловыми колебаниями даже этот зазор имеет значение, если допуски жесткие.

Роль закалки и термообработки

Температура T5 или T6 изменяет внутреннее напряжение. Она не сильно изменяет скорость расширения, но влияет на возникновение напряжения при движении.

Профиль в состоянии T6 лучше сопротивляется деформации. Но если расширение блокируется, внутреннее напряжение становится выше. Это может привести к изгибу или разрушению соединения.

Почему выбор сплава по-прежнему имеет значение для контроля расширения

Даже если разница в скорости расширения невелика, выбор сплава связан с другими факторами. Прочность позволяет увеличить длину пролетов. Обработка поверхности влияет на поглощение тепла. Темные анодированные профили быстрее нагреваются на солнце.

Дизайнеры не должны изолировать экспансию от выбора других материалов. Все решения взаимодействуют.

Различные сплавы для экструзии алюминия имеют одинаковые характеристики теплового расширения.Ложь

Несмотря на свою схожесть, такие распространенные сплавы, как 6063 и 6061, имеют немного разные скорости расширения, что может иметь значение при создании точных конструкций.

Выбор сплава влияет не только на прочность, но и на управление напряжением теплового расширения.Правда

Свойства сплава влияют на то, как формируется напряжение при растяжении и как профиль реагирует на ограничения.

Можно ли контролировать расширение в больших конструкциях?

Большие алюминиевые конструкции часто разрушаются не от нагрузки, а от сдерживаемого движения. Контроль расширения - это не остановка движения. Оно заключается в том, чтобы направлять его.

Тепловое расширение невозможно устранить, но его можно контролировать с помощью таких конструктивных особенностей, как компенсаторы, скользящие соединения и правильное расстояние между ними.

Этот принцип применим к навесным фасадам, каркасам солнечных батарей, транспортным системам и промышленным линиям.

Методы проектирования, используемые в крупных экструзионных системах

Наиболее распространенное решение - припуск. Профили фиксируются в одной точке и допускают скольжение в других. Это предотвращает нарастание напряжения.

Общие методы включают:

- Щелевые отверстия вместо круглых

- Плавающие кронштейны

- Резиновые или полимерные прокладки

- Телескопическая конструкция профиля

Пример с промышленными рамами

В длинных конвейерных рамах алюминиевые экструзии могут составлять более 20 метров. Рама закреплена в центре. Оба конца могут свободно перемещаться. Это позволяет сбалансировать расширение в обоих направлениях.

Игнорирование этого метода приводит к прогибанию или шуму при ежедневных температурных циклах.

Обработка поверхности и термическое поведение

Отделка поверхности изменяет скорость проникновения тепла в профиль. Темные покрытия поглощают больше тепла. Светлые покрытия отражают больше солнечного света.

Это не изменяет скорость расширения. Она изменяет температурный диапазон. Более высокий температурный диапазон означает большее движение.

Качество установки имеет такое же значение, как и дизайн

Даже хорошая конструкция выходит из строя, если монтажники слишком сильно затягивают болты. Болты должны обеспечивать движение в запланированных местах. Контроль крутящего момента и четкие инструкции имеют решающее значение.

В экспортных проектах условия монтажа зависят от страны. Четкие чертежи снижают риск.

Тепловое расширение алюминиевых конструкций должно быть допустимым, а не полностью сдерживаемым.Правда

Обеспечение контролируемого перемещения предотвращает возникновение напряжений, деформаций и разрушений в больших системах алюминиевой экструзии.

Использование более толстых алюминиевых профилей устраняет необходимость в припусках на расширение.Ложь

Толщина профиля не останавливает тепловое расширение; она изменяет только жесткость, но не перемещение.

Какие испытания проверяют поведение расширения при нагревании?

Тепловое поведение не должно опираться только на теорию. Испытания подтверждают предположения до начала массового производства или установки.

Поведение при тепловом расширении проверяется с помощью лабораторных испытаний, таких как дилатометрические испытания, испытания на термоциклирование и измерения контролируемого нагрева.

Эти испытания позволяют получить данные для инженеров и покупателей.

Испытание дилатометра - простое объяснение

Дилатометр измеряет изменение длины при контролируемом нагревании. Небольшой образец нагревается с постоянной скоростью. Датчики отслеживают расширение.

Этот тест позволяет получить точные коэффициенты расширения. Он используется при разработке материалов и проверке качества.

Испытания на термоциклирование в реальных условиях

При термоциклировании полные профили подвергаются многократному нагреву и охлаждению. Это имитирует дневные и ночные циклы.

Инженеры наблюдают:

- Постоянная деформация

- Ослабление суставов

- Растрескивание поверхности

- Шум от движения

Этот тест полезен для навесных стен и наружных рам.

Проверки на уровне производства

На экструзионных заводах чаще всего используются косвенные проверки. К ним относятся:

- Проверка размеров при различных температурах

- Проверка прямолинейности после охлаждения

- Испытания при сборке в жарких условиях

Эти действия гарантируют, что при отправке профили будут вести себя так, как ожидается.

Когда покупателям следует запрашивать данные испытаний

Не каждый проект нуждается в лабораторных отчетах. В случаях повышенного риска - да. К ним относятся:

- Очень длинные профили

- Сборки с жесткими допусками

- Экстремальные климатические регионы

Четкая коммуникация позволяет избежать споров в дальнейшем.

Лабораторные испытания позволяют точно измерить коэффициент теплового расширения алюминиевых экструзий.Правда

Дилатометр и испытания с контролируемым нагревом позволяют получить точные данные о поведении при расширении.

После выбора марки сплава испытания на тепловое расширение не требуются.Ложь

Даже при использовании известных сплавов испытания помогают подтвердить их поведение в конкретных конструкциях профилей и областях применения.

Заключение

Тепловое расширение - это предсказуемое поведение, а не дефект. Алюминиевые экструзии работают хорошо, когда движение спланировано и направлено. Четкое проектирование, правильный выбор сплава и надлежащее тестирование предотвращают большинство отказов, связанных с расширением.