Mill Finish Aluminum Vs. Anodized Aluminum: What Are the Differences?

Mill-finish and anodized aluminum serve different purposes—but how do you choose? I’ve used both in projects, and the difference in performance is night and day.

Mill-finish aluminum is raw and untreated; anodized aluminum has a thick, protective, and often colored oxide layer that enhances durability.

Understanding these differences can save you money and ensure the right finish for your environment.

What are the differences between mill and anodized aluminum?

Mill-finish aluminum is the pure, unfinished extrusion straight from the press. It has a dull, matte look, often with visible marks or scratches. There’s only a very thin natural oxide layer that offers minimal protection.

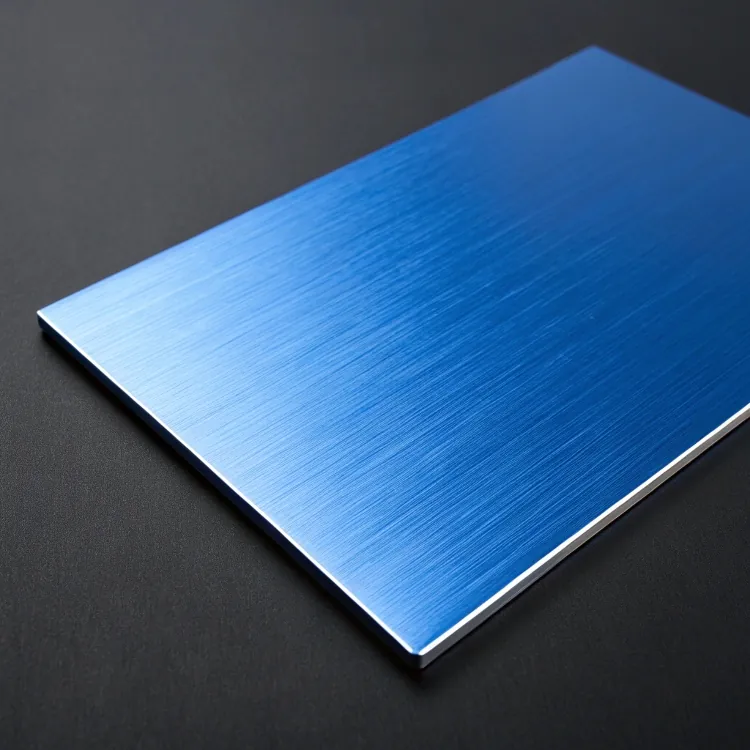

Anodized aluminum, on the other hand, is treated electrochemically to build a much thicker oxide layer. This layer is integral to the metal, doesn’t peel, and can be dyed various colors. It also resists corrosion and wear.

| Feature | Mill Finish | Anodized Aluminum |

|---|---|---|

| Appearance | Dull, raw look | Smooth, clean, optional color |

| Surface Oxide Layer | ~2–3 nm | 5–150 μm (up to 50,000x thicker) |

| Corrosion Resistance | Low | High (especially with sealed anodizing) |

| Wear Resistance | Low | High |

| UV Resistance | Poor | Excellent |

| Typical Use | Industrial/hidden parts | Architectural, decorative, outdoor structures |

Mill-finish aluminum has a thick oxide layer that prevents corrosion.False

Mill-finish only has a natural, thin oxide layer, not sufficient for long-term corrosion protection.

Anodized aluminum resists UV damage and is ideal for outdoor use.True

The anodized layer protects against weather, UV, and mechanical wear.

When is mill finish preferred over anodizing?

Sometimes, mill finish is a better fit. It’s cheaper, easier to fabricate, and faster to deliver. I’ve used it in warehouse racking, machine frames, and internal support structures—where looks and corrosion resistance didn’t matter.

Mill-finish aluminum is preferred for hidden parts, dry indoor use, or when post-processing like painting, welding, or machining is planned.

Here’s when I use it:

- Tight-budget industrial builds

- Where parts will be painted later

- Welded assemblies where anodizing1 would interfere

- Quick prototyping or temporary structures

Mill-finish aluminum is ideal for visible architectural projects.False

Mill finish lacks aesthetic appeal and corrodes faster outdoors.

Mill finish is suitable when aluminum is going to be painted or powder-coated later.True

Mill finish provides a clean base for coatings.

How does anodizing improve corrosion resistance?

The anodizing process builds a hard, porous oxide layer that’s many times thicker than natural oxidation. I’ve used this in balcony railings, outdoor signage, and even marine parts. The protection is significant.

Anodizing increases corrosion resistance by forming a dense oxide barrier that prevents water, air, and salts from reaching the base aluminum.

Why Anodized Finishes Perform Better

Barrier Layer

The anodized surface2 is sealed, making it nearly impermeable to moisture and air.

Pore Sealing

After anodizing, parts are usually sealed in hot water or chemicals, locking in color and closing microscopic pores.

Colorfastness

Anodized parts don’t chalk or fade under UV light like paints do.

| Factor | Natural Oxide Layer | Anodized Layer |

|---|---|---|

| Thickness | 2–3 nm | 5–150 μm |

| Protection | Low | High |

| UV Resistance | Minimal | Excellent |

| Wear Resistance | Low | High |

Anodizing blocks moisture and corrosive elements from reaching the aluminum.True

Sealed anodized layers are dense and prevent environmental damage.

The anodized layer can flake off over time like paint.False

Anodized layers are integral to the metal and won’t peel or flake.

What industries use FONNOV’s finishes?

I’ve followed FONNOV’s product lines—they cover a wide range, from powder coating to PVDF and wood grain finishes. Their anodized options are especially popular in construction and design.

FONNOV supplies finishes for industries like architecture, transportation, electronics, and energy infrastructure.

Where FONNOV Aluminum Finishes Are Used

| Industry | Application Examples |

|---|---|

| Architecture | Windows, doors, curtain walls, facade panels |

| Construction | Formwork, railings, structural elements |

| Transportation | Vehicle trim, trailers, railcars, marine parts |

| Electronics/Energy | Heat sinks, solar panel frames, enclosures |

| Furniture & Interior | Cabinets, decor, partition systems |

They’re well-known for their:

- PVDF3 (fluorocarbon) coatings for high-end buildings

- Color anodizing with consistent tone and depth

- Wood-grain sublimation for decorative applications

FONNOV only supplies anodized aluminum for the construction industry.False

FONNOV serves many sectors, including transportation, energy, and interiors.

FONNOV provides PVDF, wood grain, and color anodized finishes.True

Their product catalog includes a wide variety of architectural and industrial coatings.

Conclusion

Mill finish suits budget projects or post-fabrication needs. Anodized finishes offer durability, beauty, and weather resistance. FONNOV supports a wide range of industries with advanced surface treatments.

-

Discover the benefits of anodizing aluminum, including enhanced corrosion resistance and aesthetic appeal, which can be crucial for certain projects. ↩

-

Exploring the benefits of anodized surfaces can provide insights into their applications and advantages in various industries. ↩

-

Discover the advantages of PVDF coatings in high-end buildings and their role in enhancing architectural aesthetics. ↩