Machined Aluminum vs Cast Aluminum: Which Is Right For Your Project?

Many engineers and designers often feel confused when choosing between machined aluminum and cast aluminum. Making the wrong choice could mean project delays and unexpected costs.

Machined aluminum and cast aluminum have different strengths and uses. Choosing the right one depends on your project’s needs, such as strength, finish, and cost.

If you want to avoid costly mistakes and pick the best material, keep reading. I will walk you through everything you need to know.

What Is Machined Aluminum And Cast Aluminum?

Many people see aluminum parts and think they are all the same. But in reality, how the aluminum is shaped makes a big difference.

Machined aluminum is made by cutting away material from a solid block using CNC machines. Cast aluminum is made by pouring molten aluminum into a mold and letting it harden.

Let’s dive deeper.

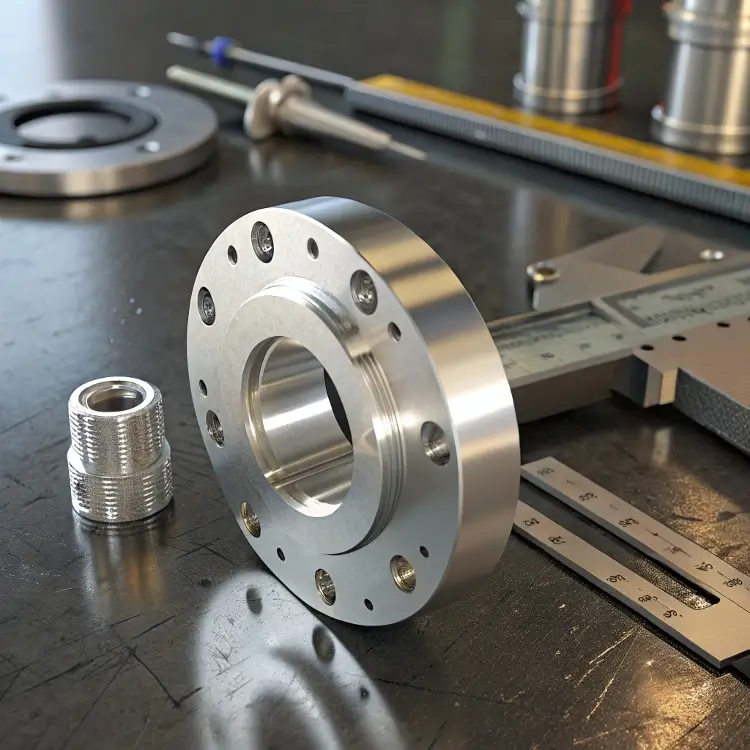

How Machined Aluminum Is Made

Machined aluminum starts with a solid block, often called a billet. CNC machines like mills and lathes remove material little by little until the final shape appears. The process allows for very tight tolerances and smooth finishes.

| Feature | Machined Aluminum |

|---|---|

| Process | Subtractive (cutting) |

| Tolerances | Very high (±0.01mm possible) |

| Surface Finish | Smooth, ready for finishing |

| Best For | Precision parts, prototypes |

How Cast Aluminum Is Made

Cast aluminum involves heating aluminum until it melts and then pouring it into a mold. Once it cools and hardens, the aluminum takes the shape of the mold. This method is good for making complex shapes at lower costs when done in large volumes.

| Feature | Cast Aluminum |

|---|---|

| Process | Molding molten metal |

| Tolerances | Medium (±0.5mm typical) |

| Surface Finish | Rougher, needs finishing |

| Best For | High-volume, less precise parts |

Both methods have clear strengths. But understanding them helps avoid choosing the wrong one.

The Benefits Of Machined Aluminum?

If your project demands high precision, not all aluminum parts are equal. Some methods can meet tight tolerances, and some cannot.

Machined aluminum offers high accuracy, great surface finish, strong mechanical properties, and flexible customization options.

Let’s look closer.

Precision And Tolerance

Machining allows me to hold extremely tight tolerances. Parts fit perfectly with others. In industries like aerospace and medical devices, even a 0.1mm error is unacceptable.

Stronger Material Properties

Machined parts come from solid blocks, meaning there are no hidden voids or bubbles inside. This makes them much stronger and more reliable. Cast parts, by comparison, can sometimes have internal defects.

Better Surface Quality

When we machine aluminum, the cutting tools create smooth surfaces that often need very little finishing afterward. If you want a brushed, anodized, or mirror finish, machined surfaces are ideal starting points.

Ideal For Prototypes And Customization

When the design is still changing, or the production volume is small, machining is the smarter choice. It is faster to tweak a CNC program than to redesign and remake a casting mold.

The Benefits Of Cast Aluminum?

When producing parts in big volumes, not every method is cost-effective. Choosing wisely can save a lot of money.

Cast aluminum allows for complex shapes, lower unit costs in high volumes, and faster production once the molds are ready.

Let’s see why casting is attractive for many projects.

Complex Geometries

Casting lets me create shapes that would be difficult or impossible with machining. Internal cavities, thin walls, and intricate features are much easier to form using a mold.

Lower Costs For Large Quantities

Once the mold is made, casting becomes very cost-effective. The price per part drops dramatically as volume increases. If your project needs thousands of parts, casting is usually cheaper than machining each one.

Faster Mass Production

A casting mold can make many parts in a short time. Especially with automated casting processes, production speeds are hard to beat.

Material And Surface Treatment Flexibility

After casting, parts can still be machined slightly to improve key areas. They can also be heat treated, anodized, painted, or powder coated to meet final product needs.

When to use machined aluminum vs. cast aluminum?

Choosing the right method is more than just technical. It also affects costs, timelines, and product quality.

Use machined aluminum when precision, strength, and flexibility matter most. Use cast aluminum for complex shapes, high volumes, and cost control.

Here’s how I usually decide:

When To Choose Machined Aluminum

- Low to Medium Volumes: Perfect for prototypes, custom parts, and small batch production.

- High Precision Needs: If tolerances under ±0.1mm are required.

- Superior Surface Finish: When the final look and feel are critical.

- Strong Material Requirements: No risk of internal voids or porosity.

- Design Changes Expected: Faster to adjust CNC programs than remake molds.

When To Choose Cast Aluminum

- High Volume Production: Best when making thousands of units.

- Complex Geometries: Easier to mold intricate shapes.

- Lower Cost Per Part: Once the mold is ready, costs drop fast.

- Speed After Setup: Molds can produce parts quickly.

- Tolerances Not Ultra-Critical: Good enough for less demanding assemblies.

| When To Use | Machined Aluminum | Cast Aluminum |

|---|---|---|

| Quantity | Low to medium (1-500 units) | High (1000+ units) |

| Tolerances | Very tight (±0.01mm possible) | Moderate (±0.5mm typical) |

| Cost Per Part | Higher | Lower at scale |

| Initial Setup Cost | Low (no molds) | High (mold creation needed) |

| Design Flexibility | Easy to adjust | Hard once mold is made |

| Mechanical Strength | Very strong (solid billet) | Good, but internal voids possible |

Choosing correctly will save time, money, and a lot of future headaches.

Conclusion

Machined aluminum and cast aluminum each have strong points. Picking the right one depends on your project’s needs for precision, cost, and design.