Start Form 200KG

Quote & Estimation

Begin with a thorough evaluation of the design's feasibility, followed by a prompt, detailed estimate.

Home > Vapor Chamber Phase Change Heat Sink Manufacturer

Custom aluminum vapor chamber heat sinks designed for efficient, low-profile thermal management in advanced electronics. We provide full design and processing flexibility-from core chamber structure to fin integration and surface finishes-meeting precise thermal and mechanical requirements.

Large-Scale Manufacturing:Our factory spans 1,000 mu (about 667,000 m²), with full in-house capabilities from aluminum smelting and billet casting to extrusion, surface treatment, and CNC machining.

One-Stop Solution:With 43 extrusion lines (500–5500 tons) and a dedicated mold partner, we provide fast production, custom profiles, and integrated services to simplify your supply chain.

Quality You Can Trust:Strict quality control ensures consistent dimensions, strength, and finish, reducing your risk and increasing reliability.

Fast Delivery & Cost Efficiency:Self-produced billets, in-house processing, and batch production mean faster lead times and lower overall costs.

Advanced Finishing Options:Anodizing and both vertical and horizontal powder coating lines deliver durable, high-quality surface finishes tailored to your product needs.

STEPS

Begin with a thorough evaluation of the design's feasibility, followed by a prompt, detailed estimate.

Creating a prototype to assess dimensions and ensure the mold's precision aligns with the requirements.

Producing the aluminum profile with pinpoint accuracy to the given specifications and applying desired finishes.

Tailored packaging for the extruded profiles, ensuring safe and efficient loading for prompt delivery.

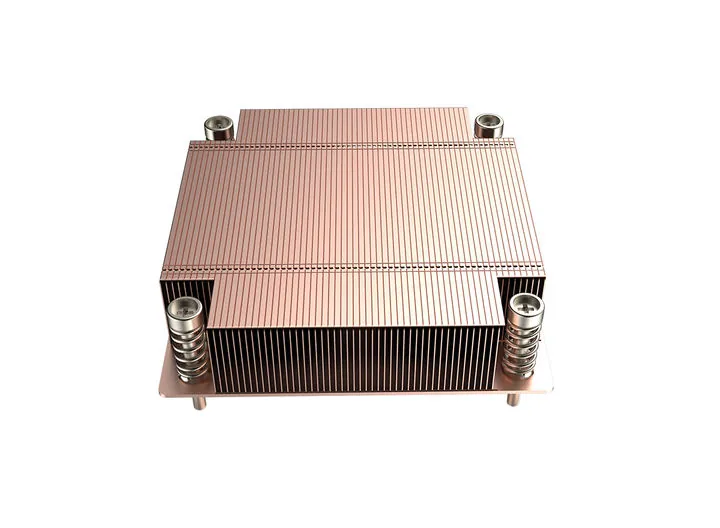

Vapor chamber phase change heat sinks utilize a sealed chamber that employs liquid-to-vapor phase transition to rapidly transfer heat across the base, delivering exceptional thermal conductivity and uniform temperature management.

These advanced heat sinks feature a thin, low-profile structure ideal for space-constrained applications, offering lightweight yet robust performance in high-density electronics, data centre modules, GPU systems, and telecom equipment.

Constructed from aluminum alloy with precision extrusion and finishing options-mill finish, anodizing, powder coating in multiple colors-they balance durability, corrosion-resistance, and design compatibility.

Our manufacturing supports complex deep processing capabilities including bending, welding, punching, decoiling, and cutting-enabling seamless integration into end-use assemblies.

With scalable production, responsive engineering support, and high customization flexibility, we are positioned as your optimal provider of phase change thermal modules for demanding B2B applications.

Start Form 200KG