Start Form 200KG

Quote & Estimation

Begin with a thorough evaluation of the design's feasibility, followed by a prompt, detailed estimate.

Home > LED Street Lamp Heat Sink Manufacturer

Our LED street lamp heat sink offers tailored solutions to meet precise thermal and mechanical requirements for outdoor lighting systems.

Large-Scale Manufacturing:Our factory spans 1,000 mu (about 667,000 m²), with full in-house capabilities from aluminum smelting and billet casting to extrusion, surface treatment, and CNC machining.

One-Stop Solution:With 43 extrusion lines (500–5500 tons) and a dedicated mold partner, we provide fast production, custom profiles, and integrated services to simplify your supply chain.

Quality You Can Trust:Strict quality control ensures consistent dimensions, strength, and finish, reducing your risk and increasing reliability.

Fast Delivery & Cost Efficiency:Self-produced billets, in-house processing, and batch production mean faster lead times and lower overall costs.

Advanced Finishing Options:Anodizing and both vertical and horizontal powder coating lines deliver durable, high-quality surface finishes tailored to your product needs.

STEPS

Begin with a thorough evaluation of the design's feasibility, followed by a prompt, detailed estimate.

Creating a prototype to assess dimensions and ensure the mold's precision aligns with the requirements.

Producing the aluminum profile with pinpoint accuracy to the given specifications and applying desired finishes.

Tailored packaging for the extruded profiles, ensuring safe and efficient loading for prompt delivery.

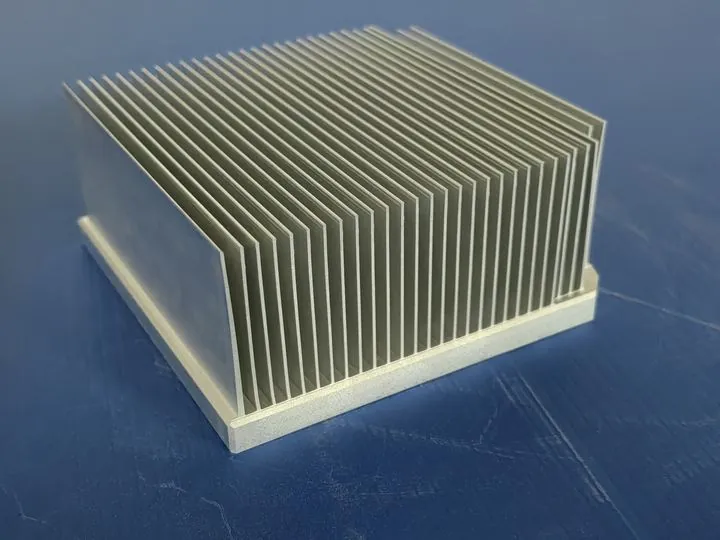

LED street lamp heat sinks are engineered to deliver superior thermal management, ensuring long-term reliability of high-power LED fixtures. The precision-machined fins and high-conductivity aluminum alloy maximize heat dissipation, protecting light output and component lifespan.

Ideal for urban street lighting, highways, and outdoor architectural lighting systems, these heat sinks offer lightweight yet durable construction designed to withstand harsh environmental conditions and simplify installation.

Equipped with a silver anodized finish, the heat sinks resist corrosion and fading, ensuring stable aesthetic and functional performance over time. This protective coating extends service life even in challenging climates.

Manufactured via advanced CNC processes and supported by both OEM and ODM services, our solutions adapt to diverse design needs-from fin architecture to alloy choice-delivering ready-to-install components with reliable quality.

With efficient production workflows and a standard lead time of 12 working days, we deliver competitive, high-performance heat sinks that empower B2B buyers to deploy projects swiftly and confidently.

Start Form 200KG