what size aluminum extrusions are used on the FolgerTech FT‑5?

Many builders choose the FolgerTech FT‑5 for its open-source frame and large build volume. But confusion often arises around its extrusion sizes. Knowing the exact profiles used in its frame helps avoid mistakes during upgrades or rebuilds.

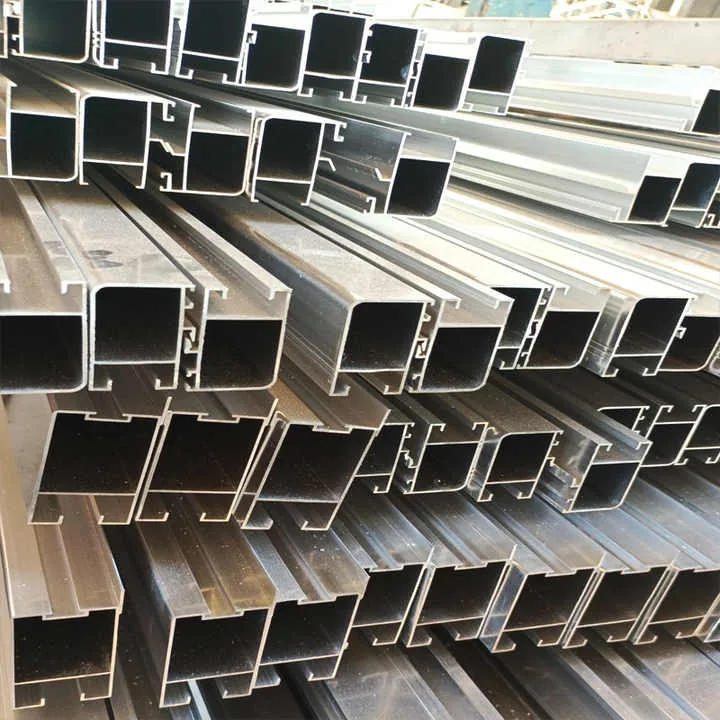

The FT‑5 uses 2020 (20×20 mm) and 2040 (20×40 mm) aluminum extrusions in its frame. These are standard T‑slot profiles, offering a lightweight but rigid structure for 3D printing.

If you’re thinking of modifying, replacing, or improving the frame, read on to learn which profiles are used, why they were chosen, how to ensure compatibility, and what options exist for stronger upgrades.

What extrusion specs fit the FT‑5?

The FT‑5 kit comes with a mix of 2020 and 2040 aluminum extrusions, both in metric T‑slot format.

FT‑5 uses 2020 extrusions for vertical and gantry structures, and 2040 extrusions for the base and bed support — providing strength where needed without adding unnecessary bulk.

According to the official FT‑5 assembly guide, the typical profile breakdown looks like this:

| 프로필 | 치수(mm) | 일반적인 사용 |

|---|---|---|

| 2020 | 20 × 20 | Uprights, gantry supports, frame edges |

| 2040 | 20 × 40 | Base structure, bed frame |

All profiles are standard aluminum T‑slot. This allows you to attach linear rails, motors, brackets, and plates using T‑slot nuts and M5 bolts. The slots make it modular and easy to customize.

Because 2020 is lighter, it’s used where rigidity isn’t as critical. 2040 adds strength at the base where bed weight and motion stress are higher.

The FT‑5 uses both 2020 and 2040 extrusions in its default frame.True

The original kit includes multiple 2020 and 2040 aluminum T‑slot beams.

All FT‑5 extrusions are 4040 profiles for extra rigidity.False

FT‑5 uses 2020 and 2040 extrusions; it does not include 4040 profiles.

Why printer frames use specific sizes?

The FT‑5 uses moderate-size extrusions not because they’re the strongest, but because they match the printer’s needs for rigidity, cost, and ease of use.

Printer frames like the FT‑5 use 2020 and 2040 extrusions to strike a balance between structural stability and lightweight modular design.

Extrusion profiles define the mechanical backbone of a printer. But using the strongest profile doesn’t always mean better printing.

- 2020 provides enough stiffness for vertical members and moving gantry assemblies.

- 2040 reinforces the bottom structure to handle the heated bed and Y-axis motion.

These profiles are also widely available, cheap, and compatible with countless brackets, braces, and mounts. This means fewer custom parts are needed, and repairs or upgrades are easier.

Lightweight extrusions reduce overall weight, making it easier to move the printer, and place it on typical desks or workbenches.

For most plastic-printing loads, 2020/2040 profiles are strong enough. Overbuilding with 4040 or 4080 extrusions adds weight and cost, but brings little benefit unless the printer is modified for high-speed or heavy-load use.

The FT‑5 frame uses 2020 and 2040 extrusions for a practical mix of rigidity and lightweight construction.True

These sizes are ideal for 3D printers with moderate loads and allow for flexible assembly.

3D printers always use large 4040 extrusions to avoid vibration.False

Smaller profiles like 2020 are sufficient for most desktop 3D printers and are standard in many kits.

How to verify frame compatibility?

Upgrading or rebuilding a printer frame means checking that all dimensions and hardware will still fit the structure.

You verify frame compatibility by comparing slot spacing, mounting hole positions, extrusion dimensions, and ensuring the new frame fits your printer’s build area and motion hardware.

Here’s how to do that:

- Measure extrusion dimensions – Confirm that replacement extrusions match the length and profile dimensions of the original.

- Check slot position – Different profiles (like 2020 vs 2040) have slots in different places. If mounting brackets expect a certain slot location, mismatch can happen.

- Compare bolt and bracket fit – Standard T‑slot accessories work with 6 mm or 5 mm slots; confirm you use matching nuts and bolts.

- Measure internal dimensions – Swapping a 2020 beam for a 4040 beam will reduce internal space unless you adjust other parts.

- Test linear rail alignment – If rails or belts are offset, extrusion size affects their height and placement. Ensure motion systems stay aligned.

If you’re keeping the bed size (300×300 mm), verify that the gantry, belts, and endstops still line up after any frame size change.

Changing extrusion sizes requires checking that bed clearance and part alignment remain correct.True

Larger or smaller extrusions affect internal dimensions and motion geometry.

All extrusions have identical slot geometry, so compatibility is never a concern.False

Slot size and spacing vary by profile; hardware must match to avoid misalignment.

Can upgrades change extrusion size?

Yes — some builders upgrade FT‑5 frames to 3030, 4040, or even 4080 profiles for added rigidity. But it’s not plug-and-play.

You can upgrade extrusion size for added strength, but this requires reconfiguring mounting brackets, motion system placement, and overall frame alignment.

Reasons to upgrade include:

- Reducing flex for tall prints or high-speed printing

- Supporting heavier beds (e.g. aluminum or glass platforms)

- Preparing the printer for enclosed builds or multi-head systems

But larger extrusions affect more than just strength:

- Increased footprint – larger beams take more space, reducing internal clearance.

- Changed mounting height – rails, brackets, pulleys may no longer align without shims or repositioning.

- Cost and weight – larger profiles cost more and add significant weight.

You may also need new brackets or printed parts. Pre-drilled parts sized for 2020/2040 may not fit 4040 profiles without rework.

Some users instead opt for reinforcements rather than a full profile swap. For example:

- Adding diagonal braces

- Using aluminum plate on vertical supports

- Bolting two 2020 profiles together for a wider beam

These keep compatibility and offer improved stiffness without total redesign.

You can upgrade an FT‑5 frame to larger extrusions, but it requires adjusting part fit and frame spacing.True

Changing profile sizes impacts component alignment and frame geometry, requiring reconfiguration.

Upgrading extrusion size can be done without changing any brackets or mounting hardware.False

Larger profiles shift mounting points, requiring new brackets or modifications to fit properly.

결론

The FolgerTech FT‑5 uses a smart combination of 2020 and 2040 aluminum extrusions — enough to deliver reliable prints, yet light and modular for home builders. Knowing the correct extrusion size helps when replacing, upgrading, or expanding the frame. If you aim for more strength, you can move to bigger profiles, but it comes with changes in alignment and structure. With the right planning, even a 2020-based frame can support a solid, large-format 3D printer.