방열판의 두 가지 유형은 무엇인가요?

Is your device heating up more than it should? Whether it’s a CPU, GPU, or SSD, the right type of heat sink can make or break your system’s performance.

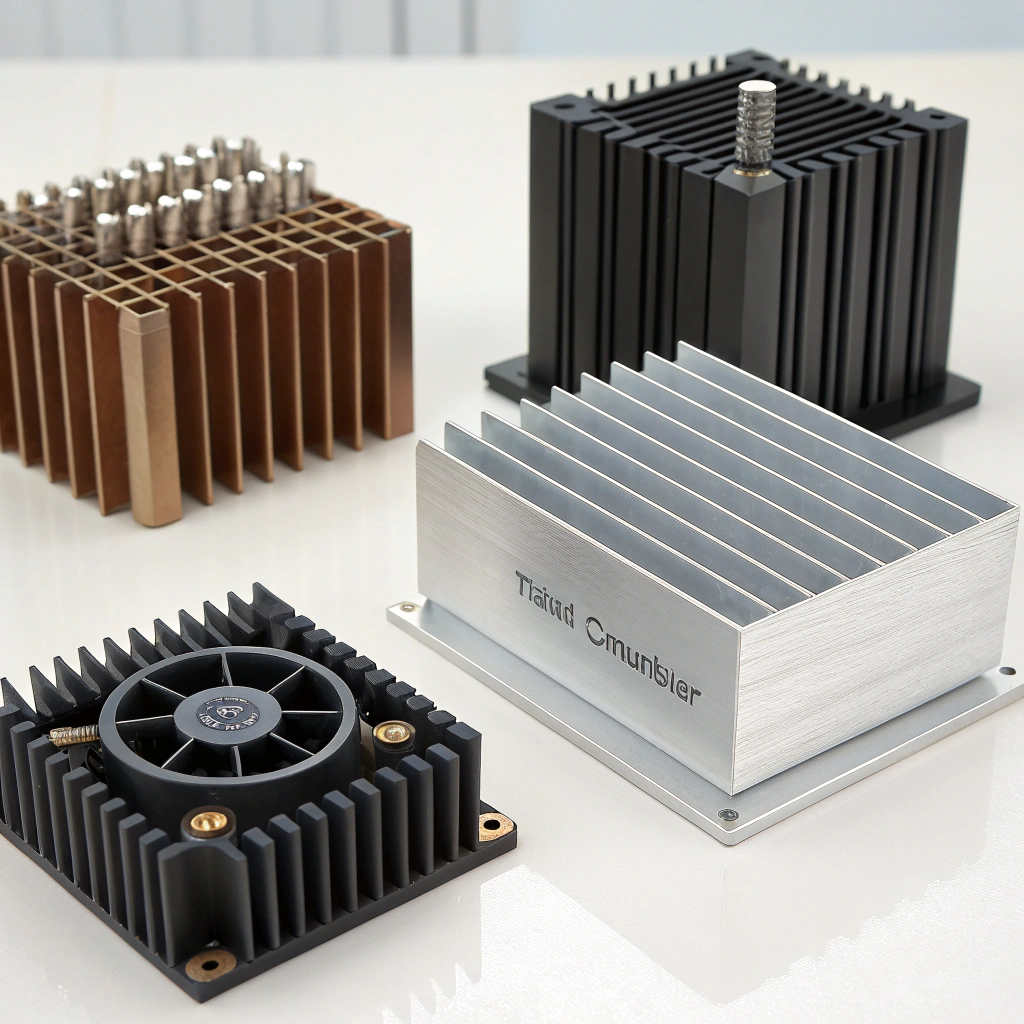

There are two primary types of heat sinks: active and passive. Active heat sinks use moving parts like fans, while passive heat sinks rely on natural airflow.

Knowing which type of heat sink to use helps you manage heat more efficiently, extend your device’s lifespan, and avoid thermal throttling. Let’s break down the types, their working principles, and practical scenarios.

What are the different types of heat sinks?

When you first look into cooling components, it might seem like there’s just one kind of heat sink. But actually, several variations exist—each serving a different need.

The three main types of heat sinks are passive, active, and hybrid. They differ in how they remove heat—either through natural convection, forced airflow, or both.

Common heat sink categories:

-

Passive heat sinks

- No moving parts

- Made of aluminum or copper

- Rely on natural convection

- Used in low-power systems

-

Active heat sinks

- Include a fan or blower

- Require power to operate

- Offer faster cooling

- Common in CPUs, GPUs, servers

-

Hybrid (or semi-active) heat sinks

- Combine passive base with optional fan

- Can switch modes depending on temperature

- Useful in smart or power-saving devices

By material:

| 재료 | 장점 | 단점 |

|---|---|---|

| 알루미늄 | Lightweight, affordable | Less conductive than copper |

| 구리 | Excellent heat conductivity | Heavier, more expensive |

| Combination | Aluminum fins + copper base | Optimized performance and cost |

By manufacturing process:

- 압출: Most common, simple, cost-effective

- Stamped: Lightweight, cheaper, less efficient

- Bonded fin: For high-performance, compact devices

- Skived: High density fins, precise performance

- Forged: Durable, excellent thermal performance

Each form factor is chosen based on airflow, size limits, power draw, and budget. For example, high-end gaming rigs need skived or bonded-fin types. Low-power routers often use stamped aluminum ones.

Hybrid heat sinks combine features of both passive and active cooling systems.True

They use natural airflow and may activate a fan when temperature exceeds a limit.

All heat sinks have built-in fans and need external power to operate.False

Only active heat sinks have fans; passive ones don’t need power.

What are the two main types of heat?

You might wonder—why all this focus on heat sinks? The reason lies in the types of heat we need to manage.

The two main types of heat in electronics are conductive and convective heat. Heat sinks manage both by transferring it away from components and into the surrounding air.

1. Conductive heat

This is the heat that travels through solid materials. For example, when your CPU heats up, it conducts heat into the attached heat sink.

- Heat flows from hot surface to cooler metal

- Metal type and contact surface affect performance

- Thicker bases or polished surfaces improve conduction

2. Convective heat

Once the heat reaches the fins, it needs to move into the air. That’s convection.

- Passive: uses natural air movement

- Active: uses fans to push or pull air through fins

- More airflow = faster heat transfer

Some devices also deal with radiant heat, but it’s minimal at the small scale of electronics.

Overview Table

| Heat Type | 설명 | Role in Heat Sink System |

|---|---|---|

| 전도 | Transfers heat through metal | Moves heat from chip to fins |

| 대류 | Transfers heat into air | Removes heat from the fins |

| Radiation | Emits heat as infrared | Minor, not significant here |

Without effective conduction and convection, your heat sink becomes a piece of warm metal. That’s why design, materials, and airflow all matter.

Convection is the main method heat is transferred from a heat sink into the air.True

Fins use air flow to carry away heat via convection.

Heat sinks cool devices mainly by absorbing radiation.False

Radiation is minimal in electronics cooling; conduction and convection are key.

What is the difference between an active and passive heat sink?

People often confuse the two or think active means “better.” That’s not always true. Choosing the right one depends on your system’s heat output and design goals.

An active heat sink includes a fan or blower to push air across the surface, while a passive heat sink uses only natural airflow to remove heat.

Active heat sink

- Adds fan to increase airflow

- Moves heat faster than passive

- Great for high-power chips

- Requires power, may make noise

- More moving parts = higher risk of failure

Passive heat sink

- Completely silent

- No energy required

- Best for low-wattage devices

- Needs good ventilation

- May overheat if air is stagnant

비교 표

| 기능 | Active Heat Sink | Passive Heat Sink |

|---|---|---|

| Air movement | Fan-assisted | 자연 대류 |

| 소음 | Yes (depends on fan) | No noise |

| 유지 관리 | May need fan cleaning | 매우 낮음 |

| 효율성 | Higher (in short term) | Lower but consistent |

| Power requirement | Needs electricity | No power needed |

| 사용 사례 | CPUs, GPUs, high-load systems | SSDs, routers, fanless PCs |

So, it’s not that one is better—it’s about matching the solution to your system’s thermal design.

Passive heat sinks have no moving parts and do not require power.True

They rely on natural airflow to remove heat.

Active heat sinks are completely silent and maintenance-free.False

They contain fans, which create noise and may need cleaning.

Is it okay to use SSD without a heatsink?

If you’ve bought a fast NVMe SSD, you might be wondering—do I really need a heatsink? The answer isn’t always yes, but it can depend on usage.

It is technically okay to use an SSD without a heatsink, but under heavy workloads, it may throttle performance or reduce long-term reliability.

When heatsinks matter

- Gen 4 & Gen 5 NVMe drives: These get very hot. Without a heatsink, they often hit 70–80°C under load.

- Gaming or content creation: Sustained writes or reads cause high temperatures.

- Enclosed systems: Laptops or mini PCs with limited airflow.

Without proper cooling, the SSD controller may throttle speeds to protect itself. You might see slower load times or data transfers.

When it’s okay to go without

- Basic web browsing or office work

- Low-wattage SATA SSDs

- NVMe SSDs with built-in heat spreaders

- Open air test benches with good airflow

Still, most modern motherboards now come with SSD heatsinks included. If yours doesn’t, aftermarket ones are cheap and easy to install.

SSD Temperature Table

| SSD Type | Load Temperature w/o Heatsink | With Heatsink |

|---|---|---|

| SATA SSD | 35–45°C | 35-40°C |

| NVMe Gen 3 | 50–60°C | 45–55°C |

| NVMe Gen 4/5 | 70–85°C | 50–65°C |

Even if your SSD "works fine" without one, heat will always affect lifespan. Just like with CPUs, cooler is better.

Gen 4 NVMe SSDs can reach 80°C under load and benefit from a heatsink.True

Without a heatsink, high-speed SSDs often throttle due to heat.

SATA SSDs require a large external heatsink for normal use.False

SATA SSDs run cool and typically don’t need extra cooling.

결론

Heat sinks come in many forms, but understanding the two main types—active and passive—helps you make better hardware choices. From basic convection in passive designs to fan-assisted active ones, each has its role. Whether you’re cooling a CPU, SSD, or industrial chip, matching the right heat sink to your thermal needs ensures better performance and longer device life.