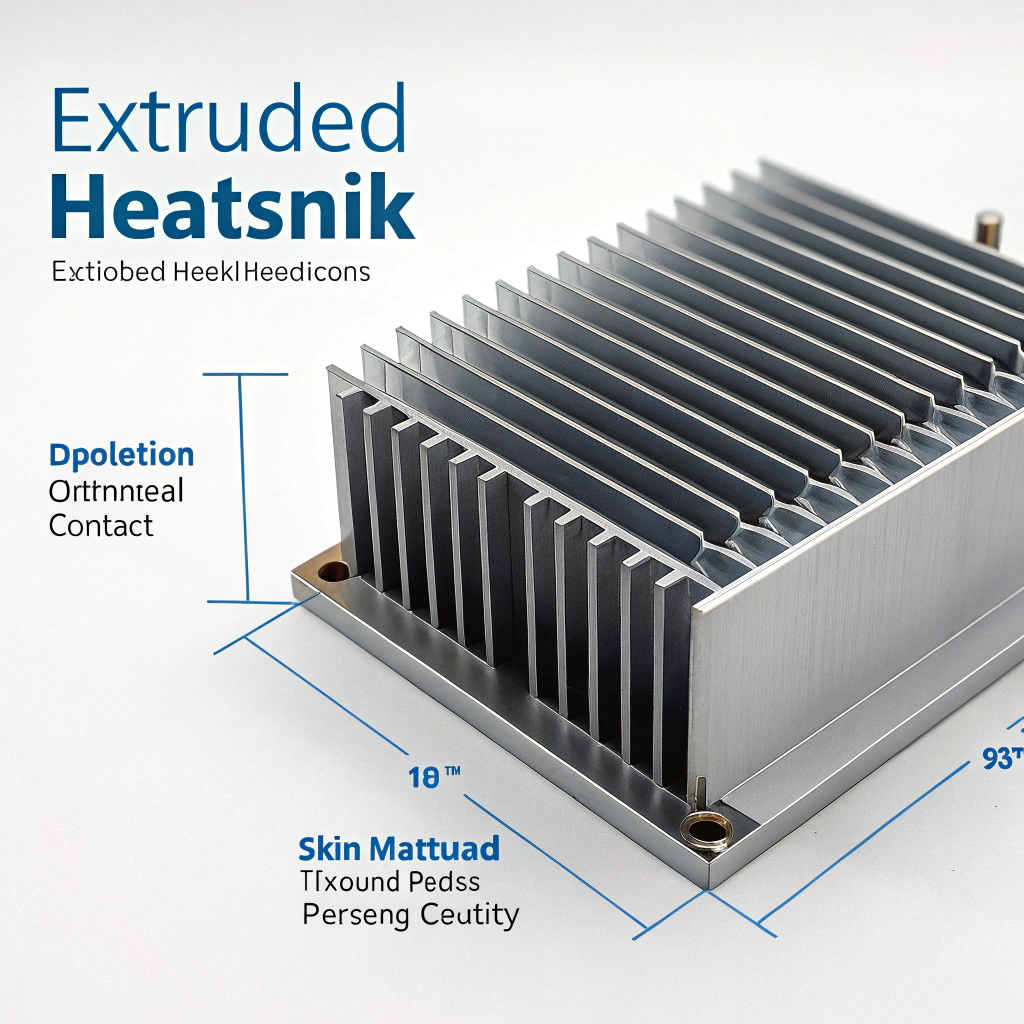

방열판용 알루미늄 압출은 얼마나 정밀한가요?

Heatsinks require tight dimensions for thermal contact—but extrusion is not CNC machining. So how precise can we really go?

Typical extrusion tolerances range from ±0.2mm to ±0.5mm, but we can achieve ±0.1mm or better in machined areas.

To meet critical specs, we often combine controlled extrusion with CNC post-processing.

What are the extrusion tolerances for our heatsinks?

Aluminum extrusion is a hot forming process. So it naturally has wider tolerances than cold machining. Tolerances vary with part size, complexity, and section.

General Tolerance Ranges

| 기능 | As-Extruded Tolerance | Post-Machined Tolerance | 참고 |

|---|---|---|---|

| Width / Height | ±0.2–0.5 mm | ±0.05–0.15 mm | Extruded tolerances grow with size |

| 평탄도 | ±0.2 mm over 100 mm | ±0.01–0.05 mm (after milling) | Cooling and residual stress affect this |

| 직진성 | 0.3 mm/m typical | Better with straightening | Long parts are more prone to bow |

| Twist / Warpage | Controlled via tension | Corrected during QC | Depends on symmetry and cross-section |

| Holes / Features | ±0.3–0.8 mm | ±0.05 mm (machined) | Extrusion can’t guarantee fine hole accuracy |

| Length (cut bars) | ±0.5 mm or more | ±0.1 mm (if faced) | End-facing or CNC needed for precision |

These values are standard in the extrusion industry. We follow Aluminum Association tolerances unless your drawing says otherwise.

Typical aluminum extrusion tolerances range from ±0.2mm to ±0.5mm for most features.True

Due to temperature, flow, and die expansion, extrusion is inherently less precise than machining.

Extruded heatsinks can guarantee ±0.05mm on all features without machining.False

Tight tolerances like ±0.05mm require CNC finishing—not feasible from extrusion alone.

Can we achieve ±0.1mm dimensional tolerance?

Yes—but only on key surfaces, and only with proper post-processing.

We can achieve ±0.1mm—or tighter—on selected critical features using CNC milling or facing.

What’s Possible

- Extruded-only parts: ±0.2mm–0.5mm is realistic for most profiles.

- CNC-finished parts: ±0.1mm or even ±0.05mm on base faces, slots, holes, and mounting bosses.

We do this often on:

- Heat-contact surfaces (baseplates)

- Bolt hole patterns

- Slot widths for slide-fit assemblies

- End faces where connectors align

How We Achieve This

- Precision extrusion setup

- Tension-straightening

- Aging and stress relief

- CNC milling, drilling, and planing on critical zones

- In-process QC using calipers, micrometers, CMMs

We recommend calling out only necessary surfaces for tight tolerance. It reduces cost.

We can hold ±0.1mm tolerances on key heatsink surfaces using CNC processing.True

Machining critical areas after extrusion allows us to meet tight requirements.

Extrusion without machining can guarantee ±0.1mm across the full profile.False

Thermal and die variation makes this impossible without post-processing.

What factors influence heatsink extrusion accuracy?

Extrusion accuracy depends on more than just machines. Everything from die design to cooling can affect your results.

Key factors affecting dimensional accuracy include die design, extrusion temperature, cooling rate, and post-processes.

Main Influences

| 요인 | Impact on Accuracy | Control Method |

|---|---|---|

| 다이 디자인 | Directs flow, controls shape | High-precision dies, wear checks |

| Die Wear | Changes dimensions over time | Scheduled maintenance |

| Extrusion Temperature | Affects flow and expansion | Tight thermal control |

| Extrusion Speed | Affects symmetry, flash, bulge | Optimize for stability |

| 냉각 속도 | Impacts shrinkage, warping | Controlled air or water cooling |

| Puller Tension | Prevents twist or bow | Precision synchronization |

| Section Symmetry | Symmetric shapes deform less | Recommend symmetric layout |

| 합금 유형 | Different alloys shrink differently | Use known materials like 6063 |

| 프로필 복잡성 | Sharp corners / thin walls distort more | Adjust die design |

| Length of Profile | Longer parts = more bending risk | Use shorter segments if needed |

Post-Extrusion Steps

- Tension straightening: aligns bars before cutting

- Aging ovens: control material properties

- CNC secondary operations: fine tune key features

- 표면 처리: may add or change dimensions slightly

Die design and cooling control are major factors in extrusion accuracy.True

Flow behavior, shrinkage, and shape fidelity depend on how metal flows through the die and cools after.

Profile length has no effect on extrusion tolerance.False

Longer profiles can bend, bow, or twist during cooling, affecting final dimensions.

Do we follow ISO or other standards for tolerances?

Yes—our tolerances follow international standards unless your drawings specify otherwise.

We follow ISO 2768, EN 755-9, and Aluminum Association tolerance standards for extruded aluminum.

Relevant Standards

- EN 755-9: For dimensional tolerances in aluminum profiles (common in Europe and Asia)

- ISO 2768-m or f: For general machining tolerances

- ASTM B221 / Aluminum Association Standards: For U.S. standard profiles

- Customer-Specific Tolerances: We follow your drawing exactly, if supplied

We always review your 2D/3D drawings before production and confirm:

- Which dimensions require tight control

- Which features can have general tolerance

- Whether 가공 is needed for fit or function

We label critical-to-function (CTQ) dimensions in our process flow to ensure accuracy.

| 표준 | Application Scope |

|---|---|

| EN 755-9 | Extrusion tolerances by size |

| ISO 2768-m/f | Machining general tolerances |

| ASTM B221 | U.S. extrusion specs |

| AA 표준 | Tolerance classes by size/type |

| 사용자 지정 | Per customer drawing |

We follow EN 755-9 and ISO 2768 standards for heatsink extrusion and machining.True

These international standards guide how we apply tolerances to aluminum profiles and post-machined parts.

Our extrusion tolerances are based solely on visual inspection.False

We follow dimensional standards and use calibrated tools to verify compliance with drawings.

결론

Aluminum extrusion gives solid shape accuracy, but for heatsinks, tight tolerances require extra steps. We combine precise extrusion, CNC, and ISO standards to deliver dimensions up to ±0.1mm—exactly where it matters.