CNC Machining Macedonia: Manufacturers & Industry Guide

1부: 1부: 시장 규모와 성장

In North Macedonia, CNC machining is quietly evolving into a key part of the national industrial base. Over the past few years, the country’s metalworking and precision engineering sectors have become more export-oriented, leveraging lower labor costs and geographic proximity to major European markets. Many local companies now serve clients in automotive, energy, and heavy machinery sectors, providing custom parts and assemblies under contract manufacturing models.

Macedonia’s industrial landscape has shifted from traditional manual machining toward digital production lines with CNC equipment. Investments from EU and regional development programs have accelerated modernization, while technical schools in Skopje and Veles supply a new generation of engineers. Companies are increasingly upgrading to multi-axis machining centers, CAD/CAM integration, and quality management systems like ISO 9001 to meet export standards.

The government’s industrial policy supports technology adoption through tax incentives and foreign investment zones. These efforts, combined with the European Bank for Reconstruction and Development (EBRD) programs, are helping small and medium enterprises (SMEs) scale up. Clusters in Veles, Bitola, and Ohrid are becoming recognized centers for precision manufacturing, connecting local suppliers with larger industrial ecosystems across the Balkans.

2부: 선도 기업

Brako DOOEL

지금 문의

Brako DOOEL, based in Veles, is one of North Macedonia’s largest and most technically capable metalworking firms. Established in the early 2000s, the company began as a steel structure fabricator but has since evolved into a modern CNC machining and fabrication enterprise. It offers large-scale machining, welding, and assembly services for industries such as infrastructure, energy, and heavy machinery.

Brako’s production capabilities include 3-axis CNC milling, large-part turning, and gantry machining for workpieces up to 20 tons. The company recently invested in a Hartford CNC milling center to enhance its precision and efficiency. Its workshop handles complex components up to 6 meters in length, with tight tolerances as fine as 0.01 mm. Brako serves both domestic projects and international clients from the Balkans and Western Europe. The firm follows ISO 9001 standards and actively participates in green manufacturing initiatives.

Svemek

지금 문의

Svemek, headquartered in Skopje, is known for its high-precision CNC turning and milling operations. Founded by a group of engineers in the late 1990s, the company focuses on complex parts machining and prototyping, offering full-service production from material selection to final inspection. Its modern workshop integrates both CNC and manual processes to ensure flexibility and high quality.

The company’s machine park features advanced Matsuura, Okuma, and Hermle machining centers, enabling 3- to 5-axis milling and 2- to 7-axis turning. This setup allows production of both small and medium batches with tight tolerance control. Svemek serves automation, industrial equipment, and electronics clients across Europe. The company emphasizes skill development, regularly training its operators to handle digital twin simulations and precision measurement systems. Its quality management is aligned with ISO 9001 standards.

Mitrotek DOOEL

지금 문의

Mitrotek DOOEL, located in Ohrid, combines traditional metalworking with modern CNC manufacturing. Founded by a local family enterprise, Mitrotek has grown into a diversified producer that handles both metal and plastic machining, offering services like laser cutting, tube bending, and component assembly. Its flexible production model appeals to clients needing mixed-material parts and short lead times.

Mitrotek operates several CNC machining centers alongside complementary equipment such as bending machines, welders, and surface finishers. This allows them to handle end-to-end production for small and medium-sized components. They serve industries ranging from automotive accessories to industrial machinery and export a growing share of their output to Western Europe. The company’s innovation lies in its integrated workflow—combining machining, forming, and assembly in one plant for efficient turnaround.

| 회사 | 설립 | 핵심 제품 | 산업 분야 | 인증 |

|---|---|---|---|---|

| Brako DOOEL | 2000s | Large CNC machining, fabrication, welding | Heavy machinery, infrastructure | ISO 9001 |

| Svemek | 1990s | 3–5 axis milling, 2–7 axis turning | Automation, industrial, electronics | ISO 9001 |

| Mitrotek DOOEL | 2000s | CNC machining, laser cutting, assembly | Automotive, general engineering | ISO 9001 |

파트 3: 무역 박람회 및 업계 이벤트

Skopje Machinery Expo

The Skopje Machinery Expo is one of North Macedonia’s key industrial exhibitions, showcasing developments in machining, metalworking, and automation. It attracts regional manufacturers, technology providers, and tool suppliers looking to expand into the Balkan market. Exhibitors often include CNC equipment distributors, software developers, and component manufacturers.

Held annually at the Skopje Fair Center, the event provides networking opportunities for Macedonian machining companies to meet European partners. Topics include smart manufacturing, additive production, and sustainability in precision engineering. Workshops and technical presentations allow visitors to see how local SMEs adopt modern CAD/CAM solutions and robotic assistance on shop floors.

Balkan Industry 4.0 Conference

The Balkan Industry 4.0 Conference is a traveling regional event that alternates between Balkan capitals, including Skopje. It focuses on digital transformation and advanced automation in manufacturing, gathering business leaders, academics, and technology suppliers to discuss innovations in CNC, robotics, and IoT applications.

During its Skopje edition, the conference highlights the role of Macedonian firms in cross-border cooperation projects. Topics include predictive maintenance, cloud-based quality control, and sustainable production. The event is a platform for knowledge exchange and helps raise the profile of local companies in the European industrial network.

| 이벤트 | 날짜 | 위치 | 하이라이트 |

|---|---|---|---|

| Skopje Machinery Expo | Annually (Spring) | Skopje | CNC technology, machining, automation |

| Balkan Industry 4.0 Conference | Annual rotation | Skopje & regional capitals | Smart manufacturing, robotics, digitalization |

4부: 글로벌 무역 정책의 영향

North Macedonia’s CNC machining industry operates in a challenging but promising trade environment. As a non-EU member but an EU candidate state, the country benefits from preferential trade access through the Stabilisation and Association Agreement, which simplifies exports to EU countries. This policy supports many machining firms that depend on orders from Germany, Italy, and Austria.

However, global material shortages and price fluctuations have created uncertainty. Steel and aluminum imports from Eastern Europe have become more expensive, pushing companies to look for suppliers in Turkey and Central Europe. While this raises production costs, it also encourages diversification and improved supply resilience.

EU environmental and energy efficiency regulations are also reshaping how Macedonian firms operate. Many SMEs are upgrading to energy-efficient CNC machines and implementing digital monitoring systems to meet sustainability targets. Meanwhile, foreign investors see North Macedonia as a cost-effective base for precision production, given its lower operating expenses and skilled workforce.

At the same time, the country faces competition from neighboring Serbia, Bulgaria, and Romania—each with more established industrial ecosystems. Macedonian firms therefore compete by offering faster turnaround times, custom flexibility, and small-batch specialization. This approach positions the industry as an agile partner within regional supply chains, even as trade conditions evolve.

5부: 결론

CNC machining in North Macedonia is gaining recognition as a capable and growing industry within the Balkan manufacturing landscape. Supported by steady investment, skilled labor, and favorable trade policies, local firms are moving beyond basic metalwork to deliver high-precision, export-ready components. Digital transformation, international partnerships, and Industry 4.0 adoption will continue to shape the sector’s competitiveness.

Nevertheless, the path ahead includes challenges. Companies must manage global supply chain risks, adopt cleaner energy sources, and keep up with the rapid evolution of machining technologies. Those that focus on workforce training, automation, and integrated manufacturing services will strengthen their position both locally and abroad. North Macedonia’s CNC machining sector, though small, has the potential to become a reliable partner in Europe’s industrial network over the coming decade.

추천 읽기:

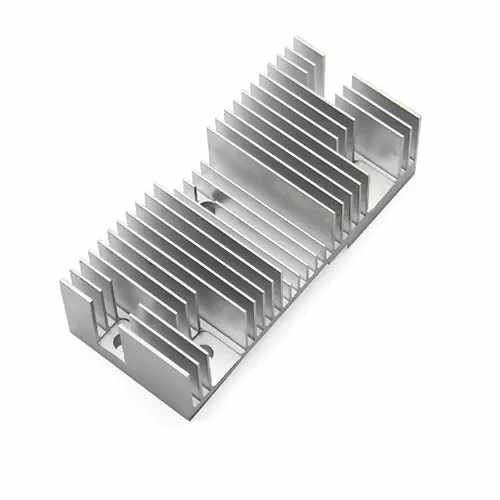

생산할 수 있는 최대 방열판 크기는 얼마인가요?

방열판에 가장 적합한 알루미늄 합금은 무엇인가요?

방열판용 알루미늄 압출은 얼마나 정밀한가요?

CNC 가공으로 알루미늄 방열판 성능을 향상시킬 수 있습니까?

방열판의 표준 포장 방법은 무엇인가요?

방열판 소재는 RoHS 및 REACH 인증을 받았습니까?

당사의 방열판이 EU 수출을 위한 CE 요건을 충족하나요?

CNC Machining Lithuania

알루미늄 프로파일 프레임이 더 많은 가치를 가져다 줄 수 있을까요?

맞춤형 알루미늄 부품

글레이징용 알루미늄 섹션

대형 알루미늄 압출