医療用液体コールドプレート

Medical devices are getting smaller, faster, and more powerful—but heat is their enemy. Without proper cooling, performance drops, and reliability suffers.

Liquid cold plates improve medical device performance by rapidly removing excess heat, ensuring thermal stability, and enhancing system longevity—especially in high-precision, high-density applications like imaging and diagnostics.

If you’re designing or sourcing for hospital equipment, this is a cooling technology worth exploring. Let’s dive deeper into why liquid cold plates are gaining traction.

How do liquid cold plates improve medical device performance?

Medical systems today operate under high heat loads in small form factors. But traditional cooling methods often fall short. Overheating compromises accuracy, device life, and patient safety.

Liquid cold plates offer higher thermal transfer efficiency, more uniform temperature control, and quieter, more compact solutions than fans or passive heatsinks.

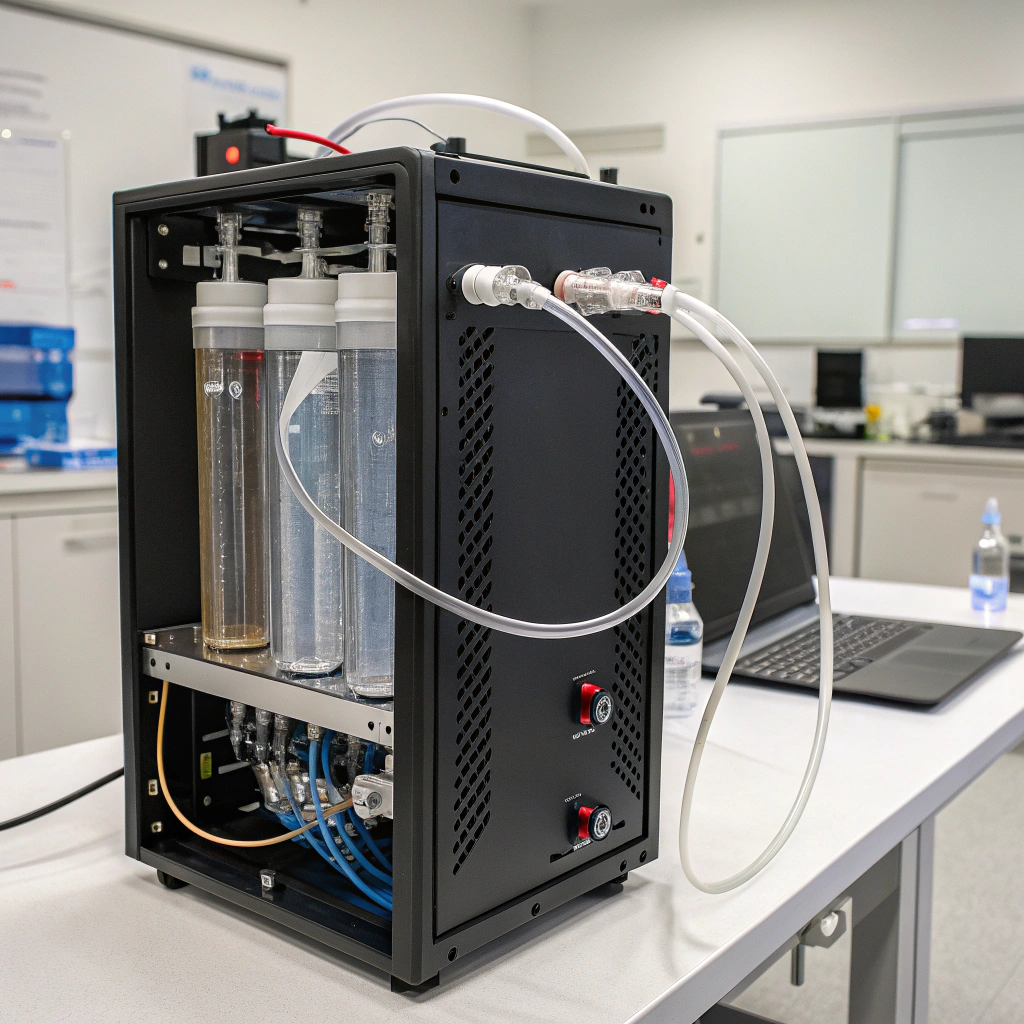

They work by transferring heat from the hot surfaces (like electronics or lasers) into a circulating liquid coolant. That coolant moves the heat away to a radiator or chiller. This fast thermal exchange protects heat-sensitive components and maintains consistent performance.

Why do they work so well?

- High thermal conductivity: Liquids like water or glycol blends carry more heat than air.

- Direct contact cooling: Plates are mounted close to heat sources.

- Closed loop control: Flow rate and temperature can be regulated precisely.

Real-world impact

In CT scanners, cold plates prevent x-ray tube overheating. In surgical lasers, they stabilize output. In diagnostic devices, they help maintain calibration. Without efficient cooling, these systems risk thermal drift, shutdowns, or reduced image quality.

Liquid cold plates can improve performance by reducing thermal variation in medical equipment.真

Better heat management helps maintain calibration and component stability.

Air cooling is always better than liquid cooling for medical devices.偽

Air cooling often cannot handle high heat densities or compact form factors.

What factors affect cold plate design for medical use?

Even the best cooling tech can fail if not customized properly. Medical equipment needs more than just thermal control—it demands reliability, hygiene, and long life.

Cold plate design must balance heat transfer, fluid flow, material compatibility, sealing, and compliance with medical standards like ISO or FDA.

Here are key design areas that influence performance and safety:

1. Thermal load and heat distribution

Estimate the wattage and hotspot locations. Use simulations to map temperature gradients. Plates should evenly distribute cooling over all key components.

2. Flow path and pressure drop

Design fluid channels to maximize surface area contact without increasing pump load. Parallel microchannels or serpentine paths often work well. Avoid sharp bends and dead zones.

| Flow Design | メリット | 欠点 |

|---|---|---|

| Serpentine | Easy to manufacture, good heat spread | Higher pressure drop |

| Parallel microchannels | High surface area, fast heat removal | More complex machining |

| Swirl or turbulence zones | Disrupt boundary layers | Increases flow resistance |

3. Material compatibility

- アルミニウムだ: Light and cheap, but less corrosion resistant.

- Copper: Excellent conductivity, but heavier and costlier.

- Stainless steel: Best for hygiene and corrosion but lower heat transfer.

For medical use, corrosion, chemical leaching, and sterilization resistance matter. Surfaces should resist disinfectants and body fluid contact.

4. Manufacturing method

- CNC machining: Precise, scalable, cost-effective.

- Friction stir welding: Strong, leak-proof, great for aluminum.

- Brazing or soldering: Allows complex internal geometries.

All cold plates should undergo pressure and leak testing. No exceptions.

5. Sterilization and hygiene

Avoid porous materials or joints that trap fluids. Design for easy cleaning. If cold plates interact with patient-side elements, they must resist microbial growth and be sterilizable (e.g., autoclave safe).

6. Monitoring and safety

Sensors should track flow, temperature, and pressure. Redundant systems (e.g., backup pumps or passive failsafes) prevent failure in critical care.

| Design Factor | Medical Need |

|---|---|

| シーリング | Prevents contamination |

| Biocompatibility | Avoids leaching into patient systems |

| Leak detection | Early fault prevention |

| Modular ports | Enables quick service/replacement |

Medical cold plates must be easy to clean, chemically safe, and sterilizable.真

They often work near sensitive systems and patient-contact equipment.

Any commercial cold plate can be used in surgical equipment.偽

Medical-grade devices require special materials and certifications.

Are liquid cold plates safe and reliable for hospitals?

Hospitals need equipment that just works—day after day, without surprises. Adding fluid systems might sound risky, but done right, liquid cold plates are stable and low maintenance.

Modern medical-grade cold plates use leak-proof seals, inert fluids, and constant monitoring, ensuring years of reliable operation in clinical settings.

Built-in safeguards

- Non-conductive fluids: Deionized water or dielectric liquids prevent electrical shorts.

- Redundant systems: Dual pumps and sensors reduce single-point failures.

- Smart monitoring: Alarms trigger if flow or temperature falls out of range.

Hospital use examples

- MRI systems: Cold plates cool gradient amplifiers and RF transmitters.

- Laser therapy devices: Maintain power output and prevent overheating.

- Dialysis machines: Ensure safe operation during long patient sessions.

Reliability by design

Every plate undergoes pressure, flow, and thermal cycling tests. ISO 13485 standards guide cleanroom production and traceability. With proper PM (preventive maintenance), systems run 10–15 years without major issues.

When failures happen

Most issues trace back to poor fluid quality, pump wear, or lack of service. These are preventable with:

- Regular filter checks

- Scheduled fluid changes

- Pump health monitoring

Liquid cooling can be made safe for use in hospital-grade equipment with the right engineering and materials.真

Leak-proof design, safe fluids, and monitoring make cold plates highly reliable.

Liquid cold plates often fail and are unsafe in hospital environments.偽

With proper quality controls, they are used in imaging and therapy systems worldwide.

When should you use cold plates over other cooling methods?

Every technology has its place. Cold plates shine in high-performance applications—but aren’t always necessary. Choose based on heat, size, noise, and budget.

Use cold plates when devices need compact, quiet, high-efficiency cooling—especially for hotspots or sensitive imaging components.

When cold plates are the best choice

| ユースケース | Why Cold Plates? |

|---|---|

| Compact surgical tools | Silent, small form factor |

| CT/X-ray machines | High heat load, precision imaging |

| Bedside monitors | Noise-sensitive environments |

| ICU ventilators | Long-duty cycles, safety-critical |

Cold plates remove more heat per square inch than passive sinks or fans. They stabilize temperatures quickly—critical for image clarity or sensor accuracy.

When other methods work better

| シナリオ | Alternative | 理由 |

|---|---|---|

| Low power handheld device | Passive heatsink | Lower cost, no pumps |

| Large open-frame machine | Air cooling | Easier to maintain |

| Limited budget project | Heat pipe | Balance of cost and efficiency |

Considerations before switching

- Initial cost: Pumps, tubing, and heat exchangers add to the bill.

- Complexity: Design and maintenance are more involved.

- Failure modes: Fluid leaks require detection and containment.

Still, when performance, noise, and reliability matter—cold plates outperform.

Cold plates are ideal for high-precision or high-power medical equipment where airflow is limited.真

They offer better thermal control in compact or sealed systems.

Passive cooling is always sufficient for medical imaging systems.偽

These systems generate significant heat and need active thermal management.

結論

Liquid cold plates are no longer niche—they’re becoming standard in advanced medical systems. Their ability to remove heat quietly and effectively makes them perfect for imaging, surgical, and critical care devices. With proper design, they offer unmatched performance, reliability, and safety for hospitals worldwide.