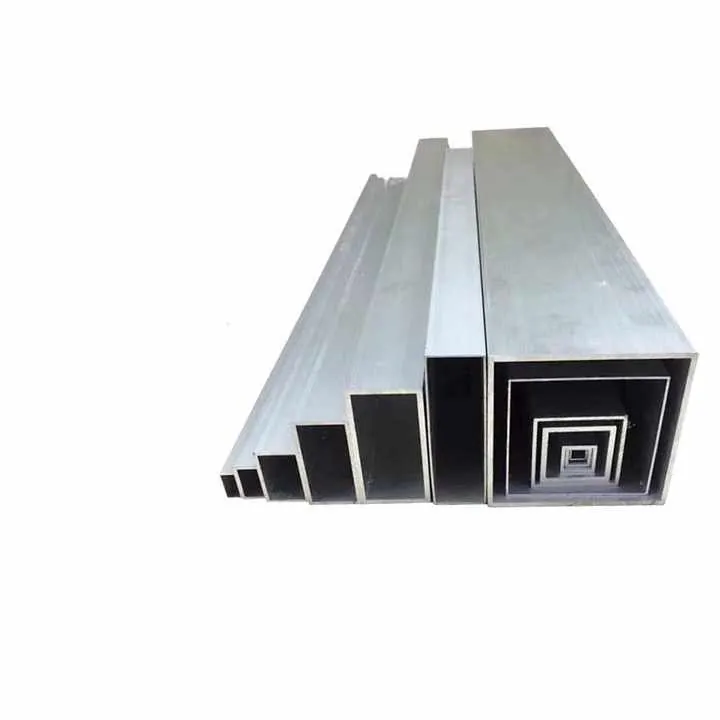

Aluminum extrusion tolerance for complex geometry?

Complex aluminum profiles fail more often than expected. Parts do not fit. Assemblies stop. Costs rise fast. Many buyers underestimate tolerance limits when geometry becomes complex.

Aluminum extrusion tolerance for complex geometry depends on profile shape, wall thickness balance, alloy, die design, and process control. Complex shapes always reduce achievable tolerance compared with simple profiles, unless secondary machining is applied.

This topic matters because complex profiles are now common in construction, solar, transport, and automation. Understanding tolerance limits early avoids redesign, delays, and hidden costs.

What tolerances apply to intricate extrusion shapes?

Intricate profiles look perfect on drawings. In production, they behave differently. Sharp corners, deep cavities, and uneven walls push extrusion to its limits. Many buyers assume tolerances stay the same. They do not.

Intricate extrusion shapes follow wider dimensional tolerances than simple profiles because metal flow becomes uneven during extrusion, especially in thin walls and hollow sections.

Why intricate shapes behave differently

Aluminum extrusion is a hot forming process. Aluminum flows through the die under pressure. In simple shapes, flow stays balanced. In complex shapes, flow speeds differ across sections.

Several factors cause tolerance variation:

- Thin sections cool faster than thick ones

- Long cantilever features bend during exit

- Hollow sections distort during quenching

- Asymmetrical designs pull material unevenly

Each issue increases dimensional deviation.

Typical tolerance ranges

For most industrial extrusions, tolerances follow industry standards such as EN or ASTM. However, complex geometry always pushes results toward the upper tolerance limit.

| プロフィール・タイプ | Typical Width Tolerance | Typical Straightness |

|---|---|---|

| シンプルなソリッド | ±0.15 mm | 1/1000 length |

| Simple hollow | ±0.20 mm | 1.5/1000 length |

| Complex hollow | +/- 0.30 mm to 0.50 mm | 2/1000 length |

These are realistic production values, not lab results.

Critical features vs overall size

Not all dimensions behave the same. External width may stay stable. Internal slots or grooves move more.

Important points to watch:

- Slot width varies more than outer width

- Corner radii increase during extrusion

- Deep channels close slightly after quench

This matters when profiles mate with fasteners or other parts.

Design decisions that help

Tolerance control starts at design stage. Simple changes reduce risk:

- Balance wall thickness where possible

- Avoid very deep narrow cavities

- Keep symmetry around centerline

- Increase corner radii slightly

These steps often cost nothing but save weeks later.

Reality check for buyers

Drawings often specify tight tolerances across all features. That creates conflict. Extrusion can meet functional tolerances, not ideal ones everywhere.

Understanding where tolerance truly matters is the key.

Complex aluminum extrusion profiles usually require wider tolerances than simple shapes due to uneven metal flow.真

Intricate shapes create unbalanced flow and cooling, which naturally increases dimensional variation.

Intricate extrusion profiles can achieve the same tight tolerances as simple solids without any process change.偽

Complex geometry reduces tolerance capability unless machining or special controls are added.

How does profile complexity affect tolerance control?

Complexity is not only about shape. It also means how aluminum behaves under heat, pressure, and speed. Every added feature increases risk.

Profile complexity reduces tolerance control because it creates uneven metal flow, higher die stress, and greater distortion during cooling and straightening.

Metal flow imbalance

Inside the die, aluminum takes the easiest path. Thin areas fill faster. Thick areas lag behind.

This causes:

- Bowing in long profiles

- Twisting in asymmetrical shapes

- Local size variation along length

Even with perfect dies, physics still applies.

Die deflection and wear

Complex dies have thin tongues and bridges. Under pressure, these parts move slightly.

Over time:

- Die openings widen

- Critical dimensions drift

- Repeatability drops

This is why early samples often look better than later batches if the die is not maintained.

Cooling and quenching effects

After extrusion, profiles are cooled. Cooling is rarely uniform in complex shapes.

Results include:

- Warping of hollow sections

- Shrinkage differences across walls

- Loss of flatness

Thicker areas retain heat longer. Thin fins cool fast and pull inward.

Straightening limitations

Stretch straightening corrects lengthwise distortion. It cannot fully correct cross-section distortion.

Key limits:

- Twisting cannot be fully removed

- Thin fins may crack if overstretched

- Internal cavities remain distorted

This sets a hard boundary on tolerance control.

Complexity scoring concept

Many engineers use an informal complexity score during quoting.

| Complexity Level | Example Features | Tolerance Risk |

|---|---|---|

| 低い | Solid bars, flat shapes | 低い |

| ミディアム | Simple hollows, T-slots | ミディアム |

| 高い | Multi-cavity, thin fins | 高い |

Higher complexity always means higher cost or looser tolerance.

Cost vs tolerance trade-off

To control tolerance in complex profiles, manufacturers may:

- Reduce extrusion speed

- Use special die materials

- Add intermediate aging steps

- Increase inspection frequency

Each step adds cost. Buyers must decide what matters most.

Practical takeaway

Complexity multiplies tolerance risk. This is not a quality failure. It is process reality.

Clear communication early prevents disputes later.

Higher profile complexity increases the difficulty of controlling extrusion tolerances.真

Complex shapes cause uneven flow, die deflection, and cooling distortion, which reduce tolerance control.

Extrusion speed has no impact on tolerance control in complex aluminum profiles.偽

Slower extrusion speeds are often required to improve tolerance stability in complex shapes.

Can machining compensate for extrusion tolerances?

Extrusion alone cannot solve every tolerance problem. Machining exists for a reason. But machining is not free, and it has limits.

Machining can compensate for extrusion tolerances on critical features, but it increases cost and should be applied only where function demands precision.

What machining does well

Machining removes material in a controlled way. It excels at:

- Slot width control

- Hole position accuracy

- Flatness and parallelism

- インターフェース面

These features often matter most in assembly.

What machining cannot fix

Machining does not correct everything:

- Overall twist along length

- Severe bowing

- Internal cavity distortion without access

If the base extrusion is too far off, machining becomes inefficient.

Hybrid tolerance strategy

The best approach often combines extrusion and machining.

Steps usually look like this:

- Extrude within realistic tolerance

- Identify functional features

- Machine only critical zones

- Leave non-critical areas as-extruded

This keeps cost under control.

Cost impact overview

| Feature Type | 押出のみ | With Machining |

|---|---|---|

| External width | 低コスト | ミディアム |

| Internal slot | ミディアム | High accuracy |

| Precision hole | Not possible | 必須 |

| Flat mounting face | 限定 | 素晴らしい |

Machining shifts cost from tooling to labor and cycle time.

Design for machining from start

Problems arise when machining is added late. Smart designs allow easy fixturing.

Helpful design choices:

- Add flat reference faces

- Avoid deep unreachable pockets

- Group machined features together

- Keep machining direction simple

These reduce cycle time and scrap.

Tolerance stack control

Machining also helps manage tolerance stacks in assemblies. Instead of tightening every extrusion tolerance, precision is added only where parts meet.

This approach improves yield.

Buyer mindset shift

Extrusion is for shape. Machining is for precision. Expecting extrusion to behave like machining leads to frustration.

Using both correctly delivers stable results.

Machining is effective for improving accuracy on critical features of aluminum extrusions.真

Machining allows precise control of features such as slots, holes, and flat surfaces.

Machining can fully correct severe twisting and bowing caused during extrusion.偽

Machining cannot economically fix large-scale distortion along the profile length.

Which inspection techniques measure complex geometry accuracy?

Measuring complex geometry is harder than making it. Many disputes come from measurement methods, not actual defects.

Accurate inspection of complex extrusion geometry requires a mix of coordinate measurement, optical scanning, and functional gauges rather than simple calipers alone.

Limits of basic tools

Calipers and micrometers work for simple dimensions. They fail with:

- Internal cavities

- Irregular profiles

- Twisted sections

Relying only on basic tools hides real issues.

三次元測定機

CMMs are common for complex profiles.

They offer:

- High point accuracy

- Repeatable results

- Data export for analysis

However, CMMs require skilled operators and stable fixturing.

Optical and laser scanning

For highly complex shapes, scanning is useful.

福利厚生は以下の通り:

- Full profile capture

- Fast comparison to CAD

- Visual deviation maps

Limits include surface reflectivity and resolution limits on sharp edges.

Functional gauges

Sometimes, the best inspection is functional.

例を挙げよう:

- Go/no-go gauges

- Assembly fit tests

- Sliding tests

If the part works in assembly, it often passes function even if some dimensions drift.

Inspection method comparison

| 方法 | 精度 | スピード | ベストユース |

|---|---|---|---|

| キャリパー | ミディアム | 速い | Simple features |

| CMM | 高い | ミディアム | Critical dimensions |

| Laser scan | 中~高 | 速い | Complex geometry |

| Functional gauge | Function-based | 速い | Assembly fit |

No single method solves all needs.

Inspection frequency matters

Complex profiles need more frequent checks, especially early in production.

Best practice includes:

- First article inspection

- インプロセス・チェック

- Final batch sampling

Skipping early checks increases scrap risk later.

Communication of results

Inspection reports must match drawing intent. Over-measuring irrelevant features creates confusion.

Clear definition of critical dimensions keeps focus on what matters.

Complex aluminum extrusion geometry often requires advanced inspection methods beyond basic calipers.真

CMMs, scanning, and functional gauges are needed to assess complex features accurately.

Functional testing is unreliable and should never be used for extrusion inspection.偽

Functional gauges are valuable when the real requirement is assembly fit, not isolated dimensions.

結論

Complex aluminum extrusion geometry always challenges tolerance control. Better results come from realistic design, selective machining, and proper inspection. Understanding process limits early reduces cost, delays, and quality disputes.