Aluminum extrusion compatibility with adhesive bonding?

Many bonded aluminum parts fail long before design life. Debonding, cracking, and sudden separation often appear without warning. These failures usually trace back to poor understanding of aluminum extrusion and adhesive compatibility.

Aluminum extrusion is compatible with adhesive bonding when the correct adhesive system, surface finish, pre-treatment method, and joint design are matched to the application conditions.

Adhesive bonding is not a simple replacement for welding or fasteners. It is a system decision. Each step affects long-term reliability.

What adhesives work best with aluminum surfaces?

Many projects choose adhesives too late. By then, extrusion design and surface state are already fixed. This creates risk.

Structural epoxies, polyurethanes, and acrylic adhesives work best with aluminum surfaces because they provide strong adhesion, gap tolerance, and durability under load and environmental exposure.

Aluminum has a natural oxide layer. Adhesives bond to this oxide, not to pure metal. This makes adhesive chemistry critical.

Structural epoxy adhesives

Epoxy adhesives are the most widely used for aluminum extrusion bonding.

主な特徴

- High shear and peel strength

- Excellent temperature resistance

- Strong chemical resistance

They work well for load-bearing joints. Cure time can be long, but strength is predictable.

Limitations include brittleness and sensitivity to surface contamination.

Polyurethane adhesives

Polyurethane systems offer flexibility. They absorb vibration and thermal movement.

利点には以下が含まれます:

- 優れた耐衝撃性

- Better performance under dynamic loads

- Moderate surface preparation tolerance

They are often used in transport and enclosure applications.

Acrylic adhesives

Acrylic adhesives cure fast and tolerate less-than-perfect surfaces.

メリット

- Fast fixture time

- Good strength on aluminum

- Reduced surface prep needs

However, odor and lower temperature resistance may limit use.

Adhesive selection comparison

| Adhesive Type | ストレングス・レベル | 柔軟性 | 典型的な使用例 |

|---|---|---|---|

| エポキシ樹脂 | 非常に高い | 低い | 構造フレーム |

| ポリウレタン | ミディアム | 高い | Dynamic assemblies |

| Acrylic | 中高 | ミディアム | Fast assembly lines |

| Silicone | 低い | 非常に高い | Sealing only |

Choosing adhesive based only on strength is a mistake. Environmental exposure, load type, and production speed matter just as much.

From bonding failures reviewed in production, wrong adhesive choice is one of the top three root causes.

Structural epoxies provide the highest load-bearing capability for bonded aluminum extrusions.真

Epoxies offer high shear strength and stable performance when properly applied.

Silicone adhesives are ideal for structural bonding of aluminum extrusions.偽

Silicones lack the mechanical strength needed for structural aluminum joints.

How does surface finish affect bond strength?

Many bonding problems look like adhesive failure. In reality, they are surface failures.

Surface finish directly affects bond strength because roughness, cleanliness, and oxide condition determine how well adhesive wets and anchors to aluminum surfaces.

Adhesives rely on mechanical interlocking and chemical attraction. Both depend on surface condition.

Smooth versus rough surfaces

Very smooth surfaces reduce mechanical keying. Very rough surfaces trap air and contaminants.

An optimal surface has:

- Controlled roughness

- Uniform texture

- No loose particles

Extruded aluminum often has die lines. These can help or hurt bonding depending on direction and depth.

Effect of anodized surfaces

Anodized aluminum can bond well if done correctly.

主なポイント:

- Thin anodic layers are acceptable

- Sealed anodizing reduces bond strength

- Dye residues can interfere with adhesion

For structural bonding, unsealed anodizing or bare aluminum is often preferred.

Influence of surface contamination

Common contaminants include:

- Oils

- Dust

- Oxide smut

- Handling residues

Even invisible contamination can reduce bond strength by more than 50 percent.

Surface finish and bond performance

| 表面状態 | Bond Strength Trend | リスクレベル |

|---|---|---|

| Clean, etched | 非常に高い | 低い |

| As-extruded | ミディアム | ミディアム |

| Anodized sealed | 低い | 高い |

| Oily or dusty | 非常に低い | 非常に高い |

Surface finish must be specified early. Leaving it undefined invites inconsistency between batches.

From field experience, consistent surface finish reduces bond variation more than changing adhesive brands.

Controlled surface roughness improves adhesive bonding strength on aluminum extrusions.真

It enhances mechanical interlocking and adhesive wetting.

A smoother aluminum surface always produces stronger adhesive bonds.偽

Overly smooth surfaces reduce mechanical anchoring and bond reliability.

Can pre-treatment improve bonding reliability?

Skipping pre-treatment is a common shortcut. It is also one of the most expensive mistakes over time.

Pre-treatment improves bonding reliability by cleaning, activating, and stabilizing aluminum surfaces, ensuring consistent adhesion across production batches.

Pre-treatment does not mean complex chemistry only. Even simple steps make a large difference.

Mechanical pre-treatment

機械的方法には以下が含まれる:

- Light abrasion

- ブラッシング

- Grit blasting

These methods increase surface area and remove weak oxide layers. Control is critical. Over-abrasion causes embedded debris.

Chemical pre-treatment

Chemical treatments are more consistent.

Common methods:

- Alkaline cleaning

- 酸エッチング

- 変換被膜

These remove oils and create a chemically active surface.

Conversion coatings and primers

Some bonding systems use primers.

福利厚生は以下の通り:

- Improved adhesion

- Corrosion protection

- Process consistency

Primers act as an interface layer between aluminum and adhesive.

Pre-treatment process flow

| ステップ | 目的 | スキップした場合のリスク |

|---|---|---|

| クリーニング | 油分を除去する | Adhesive failure |

| エッチング | Activate surface | Weak bonding |

| すすぎ | Prevent residue | 化学攻撃 |

| 乾燥 | Moisture removal | Voids |

Each step builds reliability. Missing one step often shows up months later as delayed failure.

Cost versus reliability

Pre-treatment adds cost and time. However, failure costs are higher. Warranty claims, recalls, and redesigns far exceed pre-treatment expense.

From long-term project reviews, consistent pre-treatment is the strongest predictor of bonded joint success.

Surface pre-treatment significantly improves long-term adhesive bonding reliability.真

It ensures clean and chemically active aluminum surfaces.

Pre-treatment only affects appearance and not bond performance.偽

Pre-treatment directly controls adhesion strength and durability.

Which joint designs suit bonded aluminum extrusions?

Even the best adhesive fails in a poor joint design. Geometry matters as much as chemistry.

Bonded aluminum extrusions perform best with joint designs that maximize shear loading, bond area, and stress distribution while minimizing peel and cleavage forces.

Adhesives are strongest in shear and weakest in peel.

Preferred joint types

Best performing designs include:

- Lap joints

- Scarf joints

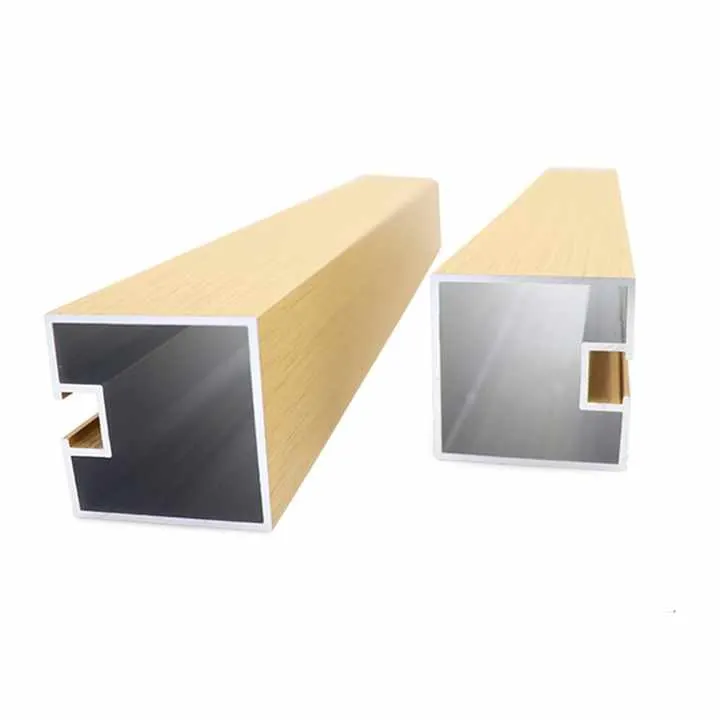

- Tongue and groove profiles

These designs spread load over a larger area.

Joint designs to avoid

High-risk designs include:

- Butt joints under tension

- Single-point bonding

- Sharp corner load paths

These concentrate stress and promote crack initiation.

Bond line thickness control

Adhesives need controlled thickness.

Too thin:

- Starved joints

- Poor stress absorption

Too thick:

- 強度が低い

- Increased creep

Most structural adhesives perform best within a defined thickness range.

Joint design performance comparison

| Joint Type | Load Distribution | 信頼性 |

|---|---|---|

| Lap joint | 偶数 | 高い |

| Scarf joint | Very even | 非常に高い |

| Butt joint | Concentrated | 低い |

| Spot bond | Very concentrated | 非常に低い |

Design integration with extrusion

Extrusion allows features that help bonding:

- Bonding flanges

- Internal channels

- Alignment ribs

Using these features reduces reliance on adhesive strength alone.

From design reviews, joint geometry errors cause more failures than adhesive selection errors.

Adhesive joints in aluminum extrusions perform best when loaded primarily in shear.真

Shear loading distributes stress evenly across the bond area.

Butt joints under tensile load are ideal for bonded aluminum extrusions.偽

They concentrate stress and promote adhesive failure.

結論

Adhesive bonding works well with aluminum extrusions when adhesive choice, surface finish, pre-treatment, and joint design are aligned. Treat bonding as a system decision to achieve stable, long-term performance.