Are heat sinks suitable for automotive battery cooling systems?

Battery packs in EVs generate a lot of heat. If the heat sink fails, batteries can overheat, shorten lifespan, or even catch fire.

Yes, heat sinks can be used in EV battery cooling if designed with proper thermal capacity, vibration resistance, and automotive-grade durability.

I always consider thermal load, mounting, material stability, and test requirements when recommending a heat sink for a vehicle system.

Is this heat sink suitable for automotive battery cooling systems?

Battery systems have high energy density and work in hot and rough environments. If the heat sink can’t handle that, it will fail.

Heat sinks for EV batteries must manage high heat loads, survive wide temperature shifts, resist corrosion and vibration, and be designed for secure mounting.

Key Requirements for EV Battery Heat Sinks

| 基準 | Required Capability |

|---|---|

| 熱伝導 | Must handle high power loads from battery modules |

| Environment durability | Withstand vibration, humidity, corrosion |

| Temperature range | Work reliably from –40 °C to 125 °C or more |

| Mounting method | Must use vibration-proof design (multi-point fix) |

| 材料 | High-grade aluminum, anodized or coated |

I never assume a standard heat sink can survive inside an EV battery pack. The best ones are tested for thermal cycling, salt spray, humidity, and road shock. The shape, material, and mounting must be chosen carefully. Customization is almost always needed.

Heat sinks for EV battery systems must survive high heat and vibration.真

Battery environments are harsh, so heat sinks need to meet automotive durability requirements.

Any standard PC heat sink can be used in electric vehicles.偽

Vehicle applications require special design, materials, and testing to handle stress and temperature.

What temperatures can the heat sink withstand in EV use?

Vehicle systems get hot fast. If the heat sink can’t handle 125°C or more, it may warp or corrode.

Automotive-grade heat sinks usually withstand –40 °C to +125 °C continuously, and some tolerate short bursts up to 150 °C.

Temperature Endurance Guidelines

| タイプ | Temp Range | 備考 |

|---|---|---|

| 家電製品 | 0 °C to 85 °C | Not vehicle-grade |

| Standard industrial | –20 °C to 100 °C | Not suitable for under-hood EV use |

| Automotive-grade | –40 °C to 125 °C or more | Matches EV system requirements |

| Extended automotive | Short periods at 150 °C | For components near high-temp zones |

I always make sure the aluminum alloy and surface treatment don’t degrade in heat. The surface finish must not peel, warp, or discolor. Thermal cycling from –40 to +125 °C can cause fatigue, so I plan for that too.

Automotive heat sinks can handle up to 125°C continuously.真

This is a common spec for EV battery and controller modules.

Plastic heat sinks are recommended for vehicle battery cooling.偽

Plastic lacks the thermal capacity and temperature stability needed in EV environments.

Do you have heat sink designs for vehicle-grade applications?

Not all heat sinks are created equal. Vehicle-grade heat sinks need special structure, materials, and tests.

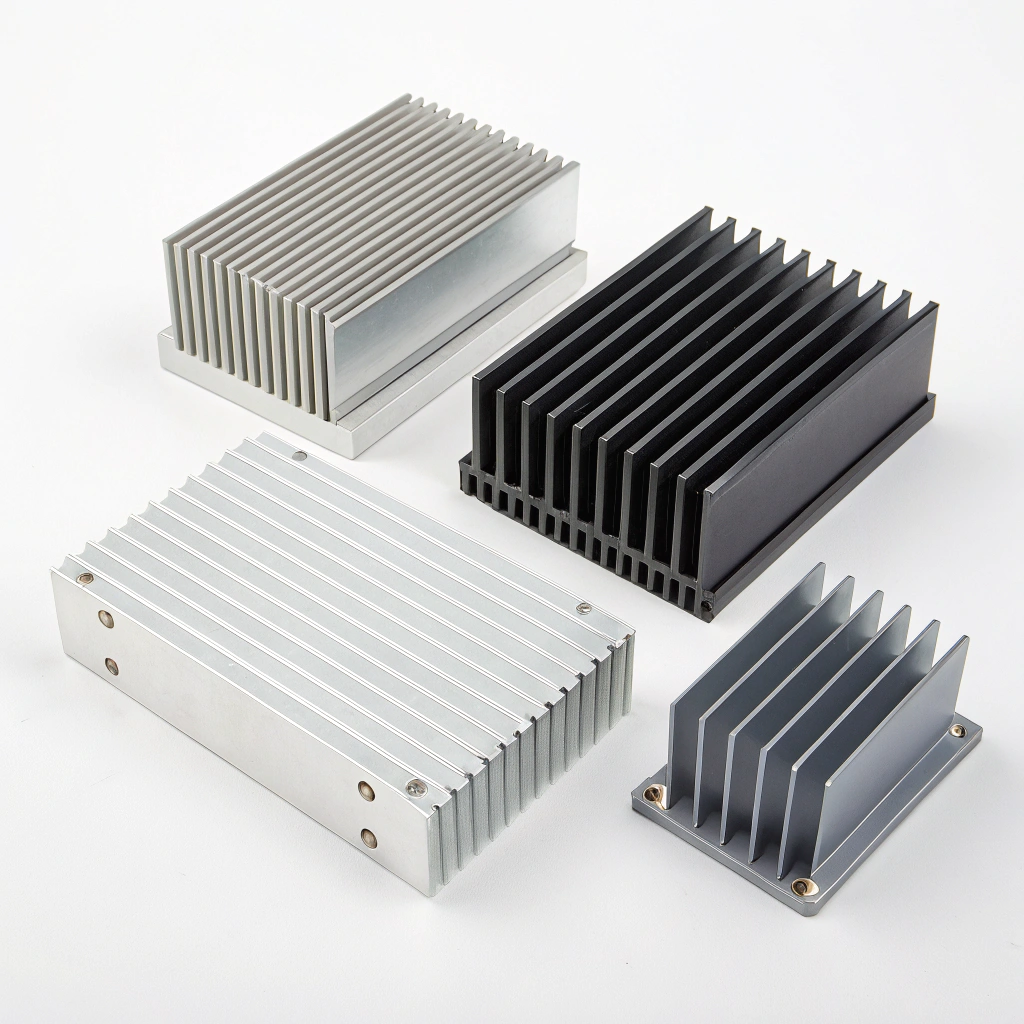

Yes, many heat sinks are custom-designed for EVs with strengthened frames, vibration mounts, and automotive surface treatments.

Vehicle-Grade Heat Sink Design Features

| 特徴 | 機能 |

|---|---|

| Reinforced ribs | Resist shock and vibration |

| Multi-point mounting | Avoid stress concentration |

| Anti-corrosion finish | Handle humidity, salt, chemical spray |

| Thermal expansion gaps | Prevent cracking in temperature swings |

| High-tolerance surface | Maintain flatness for thermal contact |

When I design for EVs, I run modal analysis to avoid resonance. I add stress relief zones or floating mounts. Copper inserts help where extra cooling is needed. Testing is done in simulated road conditions with humidity and thermal cycles.

Vehicle-grade heat sinks are often tested for vibration and salt spray resistance.真

They must survive road shocks and environmental exposure.

All aluminum heat sinks are automatically vehicle-grade.偽

Only those designed, coated, and tested for automotive use qualify.

What certifications apply to automotive-grade heat sinks?

Without proper standards, even a strong heat sink may not be accepted in EV production.

Automotive heat sinks should follow AEC-Q standards for component reliability and ISO 16750 for environmental stress tests.

Common Automotive Certifications

| スタンダード | 目的 |

|---|---|

| AEC-Q100/200 | Ensures electronic reliability in vehicles |

| ISO 16750 | Validates durability under vibration/temp |

| IATF 16949 | Quality control for automotive suppliers |

| ISO 26262 | Functional safety (if heat sink failure causes hazard) |

| RoHS / REACH | Environmental and material compliance |

In my experience, EV OEMs require at least ISO 16750-level test reports for heat sinks. Some also ask for vibration and salt fog test data. I always verify with the client which ones apply before manufacturing.

IATF 16949 is a quality management standard for vehicle part suppliers.真

It ensures process consistency and defect control in auto supply chains.

RoHS compliance is not needed for automotive heat sinks.偽

Environmental regulations still apply even to metal parts.

Can heat sinks handle vibration in electric vehicles?

Roads are rough, and EVs vibrate constantly. Loose heat sinks can break wires or overheat modules.

Yes, with strong design and correct mounting, heat sinks can handle the constant vibration found in electric vehicles.

Anti-Vibration Design Methods

| テクニック | 目的 |

|---|---|

| Structural ribs | Strengthen fins and base |

| Multi-point bolts | Spread the load and reduce shifting |

| Spring washers | Maintain clamp force under shock |

| Vibration mounts | Isolate shock from electronics |

| Modal analysis | Avoid natural frequency matching |

I test with IEC 60068 vibration standards, or real-world road tests. If heat sinks are only fixed at one point, they may loosen over time. That’s why I use stress spreaders, captive screws, and anti-loosening paste. In extreme conditions, I add shock-absorbing foam or grommets.

Heat sinks in EVs must be tested for vibration durability.真

Long-term road shock and movement require vibration-resistant design.

Mounting heat sinks with a single central bolt is best for vibration resistance.偽

Single-point mounts are more prone to loosening and stress concentration.

結論

Vehicle-grade heat sinks must do more than just cool. They must survive heat, shock, corrosion, and stress for years. With the right design and standards, they help keep EV systems safe and efficient.