Is honeycomb board good?

Sometimes a material looks perfect—until you use it. Then you start noticing the small problems. That’s often the story with honeycomb board.

Yes, honeycomb board is good when used in the right application. It offers strength with minimal weight and is often eco-friendly, but it’s not without limits.

It’s not about whether honeycomb board is good or bad. It’s about whether it fits your use case. Let’s break it down and look deeper into its strengths and limitations.

What are the disadvantages of honeycomb panels?

Sometimes materials that look great on paper don’t perform as expected. Honeycomb board has a few drawbacks you need to know before using it.

Honeycomb panels can be weak under point loads, difficult to edge finish, not waterproof unless sealed, and can deform under moisture or heavy pressure.

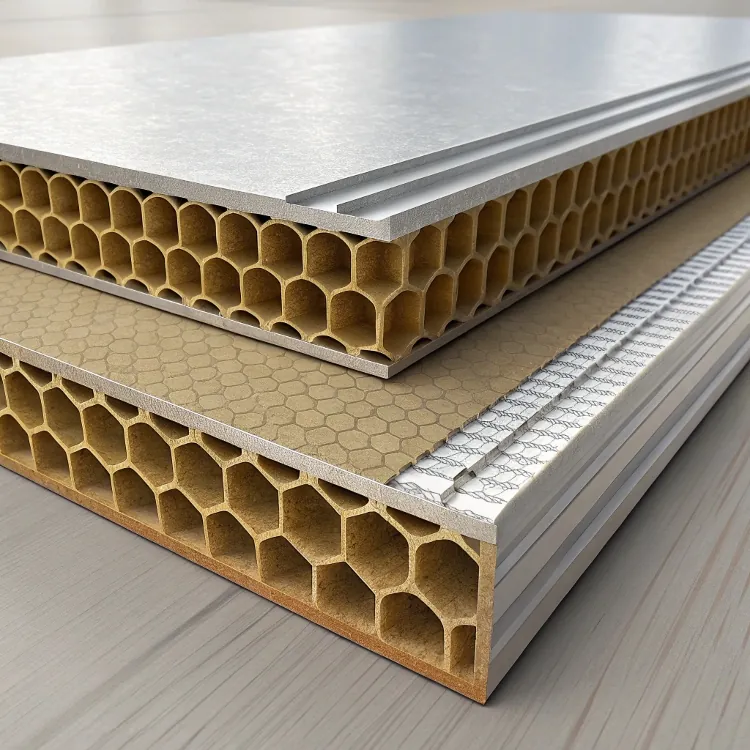

While honeycomb panels1 are great for lightweight structures, their internal paper or plastic structure limits their strength under certain types of loads. The thin outer skins and hollow core mean it doesn’t handle screws well. This is important if you’re planning to use it for cabinetry or structural furniture.

Another issue is durability in humid or wet environments. If the panel isn’t sealed properly, the core can absorb moisture, leading to warping or collapse. The edge finishing process is also more complex compared to solid wood or MDF. That adds labor cost and may limit design flexibility.

Here’s a quick comparison table:

Common Disadvantages of Honeycomb Panels

| Disadvantage | Explanation |

|---|---|

| Poor point load resistance | Not ideal for heavy objects placed directly on small areas |

| Sensitive to moisture | Especially if made from paper and not properly sealed |

| Hard to fix components | Screws and fasteners don’t hold as well as in solid panels |

| Limited design flexibility | Edge finishing is complicated and limits some design options |

When used in dry, controlled environments like interior walls or temporary exhibition booths, it performs well. But it’s not for outdoor use or heavy-duty applications without serious reinforcement.

Is honeycomb board strong?

Lightweight can mean weak, but not always. Honeycomb board surprises many with how much strength it offers—within limits.

Honeycomb board is strong in terms of surface rigidity and compression, but it is weak against concentrated forces and edge stress.

The unique hexagonal structure inside a honeycomb board gives it high compression strength2. It distributes weight evenly across its surface. This is why it’s used in aerospace, automotive, and packaging—anywhere weight reduction is key without sacrificing panel rigidity.

However, you can’t drill into it like plywood. It can’t hold screws or bolts well. If you try to put a heavy object on a small point (like a table leg), the board may buckle unless you reinforce it. That’s why it’s often sandwiched between rigid materials like MDF or aluminum sheets.

Let’s look at how its strength compares:

Honeycomb Board Strength Ratings (Approximate)

| Type of Strength | Rating (vs. solid wood) | Comments |

|---|---|---|

| Compression Strength | High | Very good load distribution |

| Tensile Strength | Medium | Depends on outer skin |

| Point Load Resistance | Low | Poor without surface reinforcement |

| Edge Load Resistance | Low | Susceptible to denting and damage |

The verdict: strong where it counts most—for large, flat surfaces under distributed loads. Weak when it comes to detailed joinery and small area pressure.

Is honeycomb actually good?

People like the word “lightweight.” But what’s the tradeoff?

Yes, honeycomb is good when your goal is to reduce weight while maintaining structure, but not suitable for all projects.

The real benefit of honeycomb board is that it saves material. That means less weight, less transport cost, and often a greener footprint. In places like temporary booths, modular interiors, packaging, and even airplane interiors, this is perfect.

The downside is, it’s not universal. If your project requires cutting, fastening, water resistance3, or long-term durability in tough conditions, you need to rethink. This is a material for clever engineers and designers who know when and how to use it.

When I used it in a packaging project for lightweight4 equipment, the result was a major logistics win. But I wouldn’t use it for building cabinetry or outdoor furniture.

Is honeycomb material good?

Materials need to be judged not just by performance, but by context.

Honeycomb material is good for non-structural uses that need low weight, low cost, and simple installation, especially in dry environments.

There are different kinds of honeycomb material: paper, aluminum, plastic. Paper honeycomb is cheapest and lightest. Aluminum honeycomb is fire-resistant and used in aerospace. Plastic offers better water resistance.

What unites them is the principle: strength through geometry. The hexagonal cell design creates strength across the surface. But they are all vulnerable at the edges and in high-moisture settings unless sealed or laminated.

Here’s how different honeycomb materials compare:

Types of Honeycomb Material

| Material Type | Strength | Water Resistance | Common Uses |

|---|---|---|---|

| Paper | Medium | Low | Furniture, packaging, partitions |

| Aluminum | High | High | Aerospace, marine, construction |

| Plastic (PP/PE) | Medium | Medium | Signboards, transport, displays |

So yes, honeycomb material5 is good—but only when matched to the right use. It saves weight, saves cost, and can even help save the planet. Just don’t expect it to do everything.

Conclusion

Honeycomb board is good when used right. It’s strong, lightweight, eco-friendly—but not for every job.

-

Explore this link to understand the limitations and potential issues of using honeycomb panels in various applications. ↩

-

Understanding compression strength is crucial for selecting materials in engineering. This resource will deepen your knowledge on the topic. ↩

-

Learn about the importance of water resistance in material selection to ensure durability and longevity in your projects. ↩

-

Understanding the significance of lightweight materials can enhance your design choices and project efficiency. ↩

-

Explore the advantages of honeycomb material to understand its applications and benefits in various industries. ↩