Milyen kérdéseket kell feltenni egy alumínium hajlító szolgáltatások cég?

If you ask the wrong questions, you get the wrong parts.

Before working with any aluminum bending company, ask questions about their capabilities, quality process, delivery timelines, and support services.

I used to assume all bending vendors were the same — until I lost $5,000 on rework because I didn’t ask the right things. Now, I follow a checklist every time.

Milyen kérdéseket kell feltenni egy alumínium hajlító szolgáltatások cég?

Relying on vague promises will almost always cost you later.

Ask about machine range, alloy compatibility, tolerances, certifications, tooling charges, and quality control systems to evaluate a bending vendor properly.

Here’s my go-to list of questions during the vendor screening call:

Technical Questions

- What aluminum alloys do you work with?

- What’s the maximum thickness and profile size you can bend?

- Can you handle hollow, complex, or thin-walled sections?

Minőségellenőrzés

- What are your typical angle and dimensional tolerances?

- Do you compensate for springback automatically?

- Do you provide inspection reports?

Lead Time & Logistics

- How long do prototypes and production runs take?

- Do you offer rush services?

- How do you pack and ship bent parts?

Pricing & Policies

- Do you charge for tooling?

- What’s your MOQ (minimum order quantity)?

- How do you handle rework or defects?

Engineering Support

- Can you review my drawing or model before bending?

- Do you offer reverse engineering or simulation?

I once saved a whole project by asking if they tested springback per alloy. Turned out they didn’t. That led me to another vendor who ran test bends and adjusted their process. The final parts fit perfectly.

Asking about springback compensation is essential when sourcing aluminum bending services.Igaz

Springback affects final bend angle and accuracy; if ignored, it leads to out-of-spec parts.

Tooling and setup costs are always included in the bending quote.Hamis

Many vendors charge separately for tooling and setup, especially for custom jobs or prototypes.

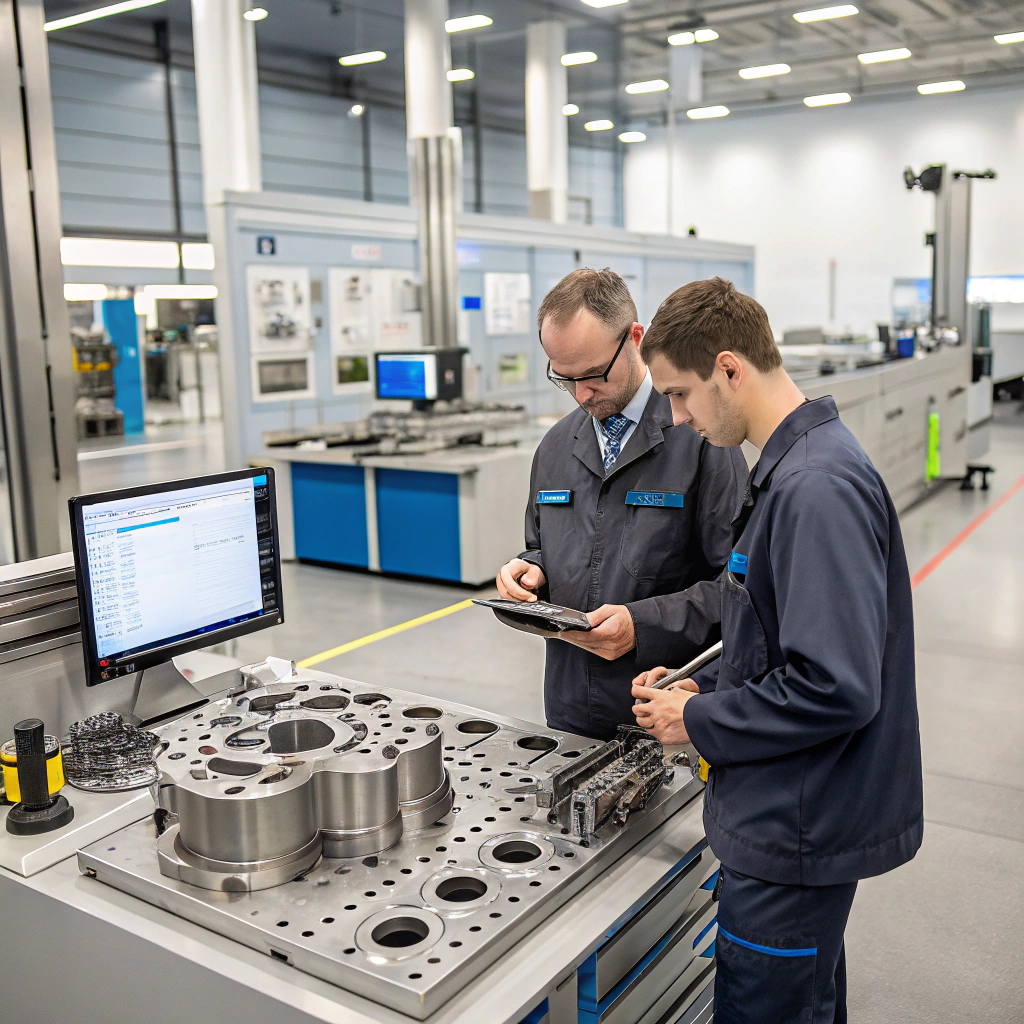

How to Evaluate the Machinery of an Aluminum Bending Company?

Old or inappropriate machines can cause distortion, cracking, or delays.

Evaluate bending machinery by checking its tonnage, profile compatibility, radius control, CNC automation, and inspection integration.

When I visit a vendor, I walk straight to their machines. A clean, calibrated CNC bender says more than any brochure. Here’s what I look for:

Key Machinery Specs to Check

| Paraméter | Miért fontos |

|---|---|

| Max Tonnage | Controls how thick or strong the profile can be |

| Bed Length | Affects the maximum profile or sheet size |

| Supported Profiles | Must match my project’s shape: round, square, rectangular, T-slot, etc. |

| CNC or Manual | CNC means better consistency and repeatability |

| Angle Compensation | Corrects for springback automatically |

| Inspection Systems | Laser sensors or CMM tools are best |

I also ask when the machine was last calibrated and what materials it’s most often used for. Machines tuned for steel might not handle aluminum well due to different springback and stress characteristics.

Red Flags in Machinery

- No nameplate or unclear specs

- Grease-stained manual press brakes only

- No inspection records

- Operator relies on visual judgment

Some vendors show off big machines but lack fine control. Others have smaller setups but run perfect batches. It’s not about size — it’s about control and consistency.

CNC-controlled bending machines offer better repeatability and accuracy than manual ones.Igaz

CNC systems automate angle control, reduce human error, and compensate for material-specific behaviors.

Bigger machines always produce better bending results.Hamis

Machine size matters, but control systems, tooling, and operator skill are more important for precision.

What Turnaround Times Do Aluminum Bending Companies Offer?

Missed deadlines can derail entire production lines.

Typical aluminum bending turnaround times range from 3 days for prototypes to 2–4 weeks for full production, depending on complexity and vendor capacity.

I never accept vague answers like “soon” or “ASAP.” I ask for exact timeframes — both best-case and worst-case. A reliable vendor gives you a realistic delivery date and meets it.

What Affects Lead Time?

| Tényező | Hatás |

|---|---|

| Rendelési méret | Small runs are quicker, large runs need scheduling |

| Profil összetettsége | Tight radii or custom shapes take more setup |

| Finishing Needs | Anodizing or coating adds 3–5 days |

| Tooling Requirements | Custom tooling can delay production by 1–2 weeks |

| Material Availability | If they don’t stock the alloy, you wait longer |

| Vendor Workload | Busy seasons may push timelines back |

For most projects, I plan for 10–14 working days from PO to shipment. If I need it faster, I ask for expedited handling — some vendors can cut time by half for a rush fee.

My Real Experiences

Once I got 50 custom-bent tubes in just 4 days — but I had to pay a 20% rush fee. Another time, I waited 6 weeks because the vendor ran out of 6082-T6 and didn’t inform me.

So now I always ask:

- What’s your standard and expedited lead time?

- Do you stock the alloy I need?

- What’s your real capacity per week?

Lead time depends on profile complexity, finish, and order size.Igaz

These factors affect setup, processing time, and vendor workload.

All vendors can deliver aluminum bending orders within one week.Hamis

Lead time varies. Rush delivery is possible, but not guaranteed without planning or extra cost.

How Do Pricing Models Vary Among Bending Service Companies?

Lowest price rarely means lowest cost in the end.

Aluminum bending pricing varies by alloy, profile, order size, bend complexity, tooling, finishing, and delivery time. Vendors may offer per-part, batch, or tiered pricing.

Understanding how they quote makes a big difference. Some charge flat per-part fees. Others break costs down into setup, tooling, and labor per unit.

Typical Aluminum Bending Cost Structure

| Komponens | Leírás |

|---|---|

| Setup Fee | One-time charge for machine configuration |

| Tooling Fee | Custom dies or mandrels for specific profiles |

| Per-Unit Cost | Usually lower for large quantities |

| Befejezés | Anodizing, powder coating, polishing, etc. |

| Szállítás | Based on weight, size, and packaging type |

Here’s an example I’ve seen for a batch of 500 U-channel profiles (6063-T5):

- Setup: $150

- Tooling: $200

- Unit Cost: $2.50/part

- Anodizing: $0.75/part

- Total: ~$2,000

But the same order at another vendor was $2,400 because their setup was slower, and their anodizing vendor charged more.

Negotiating and Understanding Discounts

Ask if they:

- Offer volume discounts (e.g. 10% off for 1,000+ units)

- Include finishing in their quote

- Offer price locks for long-term contracts

If a quote looks low, ask what’s excluded. Sometimes packaging, inspection, or even post-bending straightening is not included.

Aluminum bending prices often include setup, tooling, and per-unit charges.Igaz

These are standard components in metal bending service quotes.

Finishing costs are always included in the main bending quote.Hamis

Finishing is often quoted separately, especially for anodizing or custom coatings.

Következtetés

Choosing an aluminum bending company isn’t just about price or proximity. It’s about asking the right questions, checking their machinery, understanding their turnaround promises, and decoding their quote. When I follow this checklist, I get better parts, faster delivery, and fewer headaches.