Get More Knowledge Of Aluminum Extrusion Bending?

Many projects fail because of poor bending choices. But the right technique can turn weak designs into strong, sleek, and functional parts.

Aluminum extrusion bending is essential in many industries, and understanding it ensures better quality, performance, and cost-efficiency.

Whether you’re creating structures or parts, knowing how to bend extrusions properly can save time and money. Let’s explore everything you need to know.

What are common bending methods for aluminum extrusions?

Many engineers feel stuck choosing the best bending method. Using the wrong one often leads to cracking or inaccurate results.

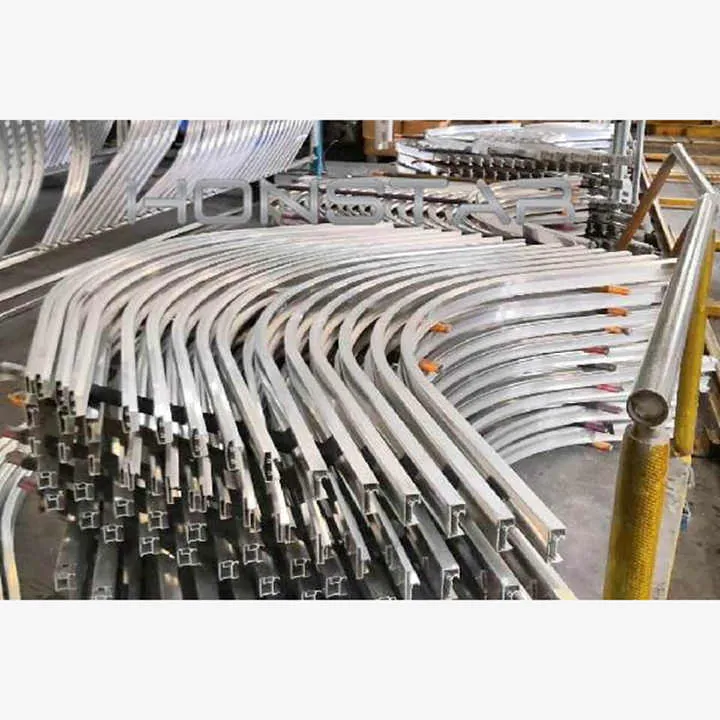

The most common aluminum extrusion bending methods include roll bending, stretch bending, press bending, and rotary draw bending.

Each method fits different needs based on profile shape, bend radius, and production volume.

1. Roll Bending

This uses a set of rollers to curve the profile gradually. It’s good for large-radius curves and long profiles. Roll bending works well with thick-walled or large-section extrusions but lacks precision for tight bends.

2. Stretch Bending

In this method, the profile is stretched while bent over a die. It reduces wrinkling and distortion. It’s ideal for window and door frames, where consistency is key.

3. Press Bending

The extrusion is placed over a die and pressed into shape. It’s fast and simple, but not ideal for precision work. This method is commonly used for square and rectangular tubes.

4. Rotary Draw Bending

This is the most accurate method, often used in complex industrial applications. The profile is clamped and pulled around a die, allowing tight and clean bends with less deformation.

Here’s a quick comparison table:

| Bending Method | Best For | Precision | Suitable Radius |

|---|---|---|---|

| Roll Bending | Large, sweeping curves | Medium | Large |

| Stretch Bending | Uniform curves for architecture | High | Medium to Large |

| Press Bending | Fast, simple bends | Low | Medium |

| Rotary Draw Bending | Tight bends and high consistency | Very High | Small |

Roll bending is best for small-radius precision bends.False

Roll bending is better for large-radius curves and lacks tight precision.

Rotary draw bending provides the most accurate bends for aluminum profiles.True

This method gives tight, clean, and accurate bends with minimal distortion.

Which aluminum alloys are best for bending profiles?

Choosing the wrong alloy leads to cracks, uneven bends, and extra costs. Not all aluminum types bend the same.

Alloys in the 5xxx and 6xxx series are generally best for bending due to their strength and ductility.

Alloys vary in how well they bend. The key is knowing their temper (hardness) and chemical composition.

Best-Bending Aluminum Alloys

Here are some popular choices:

- 6061-T6: Strong and corrosion-resistant. Needs heat treatment to bend well.

- 6063-T5: Softer and easier to bend, ideal for architectural uses.

- 5052-H32: Excellent ductility and corrosion resistance. Great for marine and automotive parts.

What Makes an Alloy Bendable?

Several factors affect how well aluminum bends:

- Ductility: Softer tempers (T4 or T5) bend more easily than harder ones (T6).

- Grain Structure: Finer grains reduce cracking risk.

- Wall Thickness: Thinner sections are easier to bend but may wrinkle.

Here’s a simple comparison table:

| Alloy | Temper | Bending Ease | Applications |

|---|---|---|---|

| 6061 | T6 | Moderate | Structural, aerospace |

| 6063 | T5 | High | Architecture, framing |

| 5052 | H32 | Very High | Automotive, marine |

6061-T6 is the easiest alloy to bend without preparation.False

6061-T6 is strong but less ductile. It requires annealing before bending.

5052-H32 is excellent for bending due to its high ductility.True

5052-H32 combines ductility and corrosion resistance, making it ideal for bending.

How to design extrusion for optimal bending?

Poor extrusion design can cause bending defects like wrinkling or cracking. But with a few tips, we can prevent those failures.

To design extrusions for optimal bending, use consistent wall thickness, avoid sharp corners, and select bend-friendly profiles.

Key Design Tips

1. Use Uniform Wall Thickness

Inconsistent thickness leads to uneven stress. Uniform walls bend more predictably.

2. Avoid Sharp Corners

Sharp inner corners increase stress and cause cracks. Use generous radii instead.

3. Minimize Hollow Sections

Hollow shapes are harder to bend. If needed, use internal supports during bending.

4. Choose Symmetrical Profiles

Symmetrical designs distribute stress evenly. Asymmetrical profiles bend unevenly.

Real-World Example

We once helped a customer redesign a complex extrusion with 3 wall thicknesses. After simplifying to a uniform wall and adding corner radii, the profile bent perfectly using rotary draw bending.

Best Practice Summary

| Design Element | Recommendation |

|---|---|

| Wall Thickness | Uniform |

| Corners | Use large radii |

| Profile Shape | Keep it symmetrical |

| Hollow Sections | Avoid or support internally |

Extrusions with sharp corners bend more easily than rounded ones.False

Sharp corners cause stress concentration and cracking during bending.

Designing with uniform wall thickness improves bending quality.True

Consistent thickness helps stress distribute evenly during the bending process.

What factors affect bend radius and quality?

Even with the right alloy and design, bending can still fail. That’s because many hidden factors influence the bend.

Key factors affecting bend radius and quality include profile thickness, bend method, alloy type, and tooling precision.

1. Minimum Bend Radius

Each alloy and temper has a safe limit. Pushing below it leads to cracking. For example, 6063-T5 can bend tighter than 6061-T6.

2. Wall Thickness

Thinner walls risk buckling or wrinkling. Thicker sections resist distortion but need more force.

3. Grain Direction

Bending against the grain can cause splits. Always check extrusion direction.

4. Tooling Condition

Worn or dirty dies cause friction and marks. Use clean, polished tools to protect the finish.

5. Operator Skill

Experienced operators adjust pressure, speed, and support to avoid defects. Their role is crucial, especially in custom bends.

Practical Table: Bend Radius Guide

| Alloy | Temper | Min. Radius (Times Thickness) |

|---|---|---|

| 6061 | T6 | 3-4x |

| 6063 | T5 | 2-3x |

| 5052 | H32 | 1-2x |

Wall thickness does not influence bend radius requirements.False

Thicker or thinner walls affect how tight a bend can be made without damage.

Tooling and operator skill both impact the quality of the bend.True

Good tooling and skilled operation ensure clean, accurate bends with less risk of damage.

Conclusion

Aluminum extrusion bending is both art and science. Choosing the right method, alloy, and design can dramatically improve results. Avoid common mistakes, and your bends will be cleaner, stronger, and more cost-effective.