Mikä on tyhjiöjuottaminen ja miksi se on välttämätön metallien liittämisessä?

Many industries struggle with creating strong, clean, and durable metal joints without warping parts or leaving residue.

Vacuum brazing is a high-temperature, flux-free metal joining technique that produces strong, corrosion-resistant bonds in a clean environment. It’s widely used for complex or high-performance assemblies.

This article will explain what vacuum brazing is, how it works, what metals it supports, common defects, and why it’s preferred in advanced manufacturing.

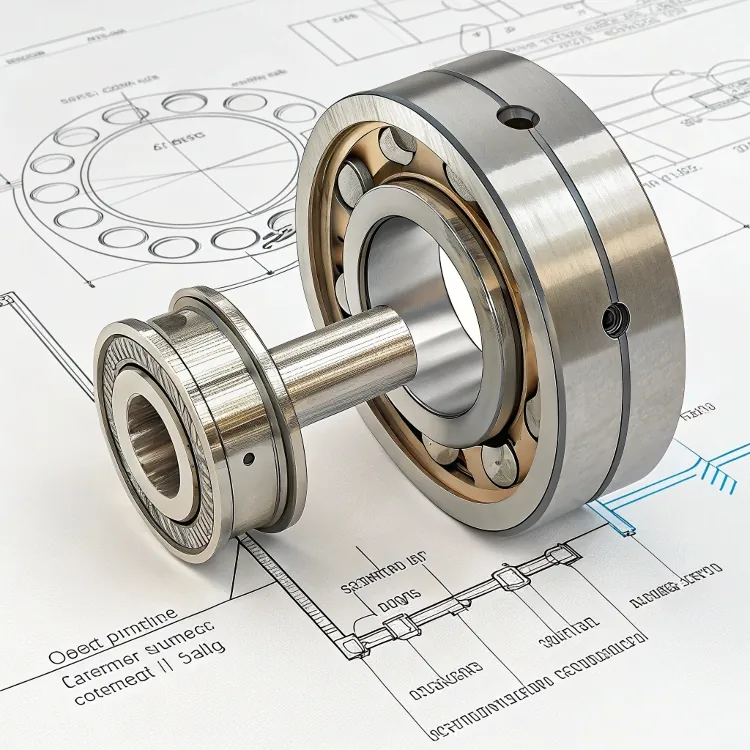

What is vacuum brazing?

Vacuum brazing sounds complex, but it’s actually a precise, clean, and high-temperature process that solves major problems in metal joining—such as weak joints, oxidation, or contamination.

Vacuum brazing is a method that joins metals using a filler metal that melts and flows between parts in a vacuum furnace, creating strong, clean bonds without flux.

Key characteristics of vacuum brazing

Vacuum brazing happens in a vacuum furnace. This special environment prevents oxidation and removes the need for flux, which is a chemical that normally helps metals bond.

Here’s what makes it unique:

| Ominaisuus | Kuvaus |

|---|---|

| No Flux Needed | Vacuum removes air and oxygen, preventing oxidation |

| Korkeat lämpötilat | Usually above 900°C, depending on filler metal |

| Tight Tolerances | Ideal for complex assemblies and minimal part distortion |

| Multiple Joints Possible | Can join many parts in one furnace cycle |

This process is common in aerospace, automotive, electronics, and high-performance tools. It is favored where part cleanliness, strength, and durability are critical.

Vacuum brazing requires the use of chemical flux to protect joints from oxidation.False

Flux is not needed in vacuum brazing because the oxygen is removed from the furnace.

Vacuum brazing produces clean joints without residues.Totta

Because it uses no flux and takes place in a vacuum, there is no residue left on parts.

How does vacuum brazing work?

Joining metal parts can lead to warping, oxidation, or chemical contamination—especially at high temperatures.

Vacuum brazing uses a high-temperature vacuum furnace to melt filler metal between close-fitting parts, bonding them without melting the base metals.

The step-by-step vacuum brazing process

Let’s look at how it works:

1. Part Preparation

All parts are cleaned of oil, dirt, and oxides. This ensures good wetting and bonding.

2. Assembly with Filler

Parts are assembled with a thin layer or foil of brazing filler metal between them. The filler usually contains silver, copper, nickel, or aluminum, depending on the base metal.

3. Loading into Vacuum Furnace

The assembly is placed inside the furnace. The air is removed to create a vacuum, typically below 10?? Torr.

4. Heating Cycle

The furnace is slowly heated in stages:

| Vaihe | Kuvaus |

|---|---|

| Ramp Up | Slow heating to remove any residual moisture |

| Soak | Hold at pre-braze temp to equalize part temperature |

| Juottolämpötila | Raise to melt filler metal (but not base metal) |

| Jäähdytys | Controlled cool-down to prevent thermal stress |

5. Final Inspection

The parts are checked for joint quality, alignment, and cleanliness.

Vacuum brazing melts the base metals to form a joint.False

Only the filler metal melts; the base metals remain solid.

The vacuum furnace removes oxygen to prevent oxidation during brazing.Totta

By removing air, oxidation is avoided, resulting in cleaner joints.

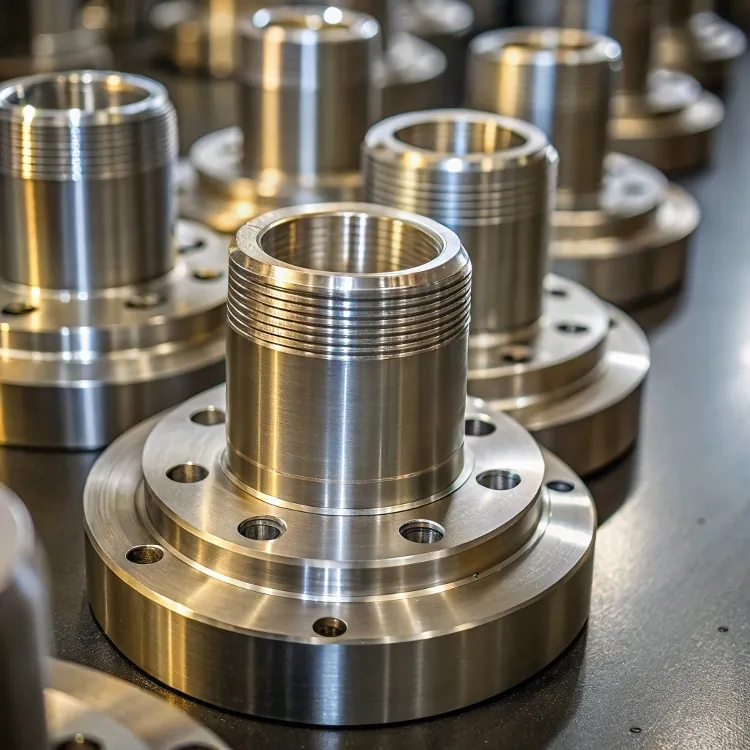

What metals can be vacuum brazed?

Many manufacturers need to join different metals or work with heat-sensitive alloys without damaging them.

Vacuum brazing is compatible with a wide range of ferrous and non-ferrous metals, especially those used in aerospace, electronics, and high-temperature tools.

Metals commonly brazed in vacuum

Here’s a table of common metals and typical filler types:

| Base Metal | Filler Metal Example | Huomautukset |

|---|---|---|

| Ruostumaton teräs | Nickel or silver alloys | Great for corrosion resistance |

| Titaani | Silver-based fillers | Needs precise temperature control |

| Inconel & Superalloys | Nickel fillers | Used in turbines and jet engines |

| Kupari | Copper-silver alloys | Excellent thermal conductivity |

| Alumiini | Aluminum-silicon fillers | Lower brazing temperatures needed |

Some metals, such as magnesium or zinc, are not typically vacuum brazed due to their volatility or high vapor pressures.

Why metal compatibility matters

Different metals expand and contract differently when heated. If not considered, joints may crack during cooling. That’s why filler selection, joint design, and heating control must be carefully engineered for each application.

Aluminum is frequently brazed using copper filler in vacuum brazing.False

Aluminum is typically brazed using aluminum-silicon fillers, not copper.

Nickel-based filler metals are suitable for joining stainless steel in vacuum brazing.Totta

Nickel fillers provide high strength and corrosion resistance, ideal for stainless steel.

What are the main vacuum brazing defects and solutions?

Even precise processes like vacuum brazing can go wrong—leading to weak joints, leaks, or failures.

Common vacuum brazing defects include voids, misalignment, poor wetting, and insufficient bonding, often caused by contamination, poor design, or incorrect temperatures.

Major defects and how to fix them

Let’s explore the key defects and solutions:

| Defect | Syy | Ratkaisu |

|---|---|---|

| Voids in Joint | Trapped gases or poor filler flow | Improve part cleaning and vacuum quality |

| Poor Wetting | Surface contamination or oxide layers | Ensure thorough cleaning and use proper alloy |

| Misalignment | Improper fixturing during heating | Use clamps or precision fixtures |

| Insufficient Fill | Not enough filler material or poor fit | Recalculate filler volume and tighten tolerances |

| Cracks After Cooling | Thermal stress or wrong filler choice | Match thermal expansion rates, use right alloy |

Each defect may affect performance in different ways. Voids may reduce strength, while poor wetting may result in joint leaks. Proper training, testing, and design review help reduce failure rates.

Surface oxides and contamination are major causes of poor wetting in vacuum brazing.Totta

Oxides block filler metal flow, so cleaning is critical for good wetting.

Using excess filler metal ensures better joint strength in vacuum brazing.False

Too much filler can lead to overflow and weaken the joint.

What benefits does vacuum brazing offer?

Choosing the right metal joining process can impact quality, cost, and performance.

Vacuum brazing offers clean joints, high strength, no post-cleaning, minimal distortion, and the ability to join complex assemblies in one cycle.

Key advantages of vacuum brazing

Here are the main benefits:

| Advantage | Miksi sillä on merkitystä |

|---|---|

| Clean Joints | No flux means no residue or contamination |

| Minimal Distortion | Uniform heating avoids warping |

| High Strength & Durability | Joints are metallurgically bonded |

| Ideal for Complex Parts | Joins multiple components in one operation |

| Broad Metal Compatibility | Suitable for many metal types |

This makes vacuum brazing ideal for high-value, precision components where strength, reliability, and cleanliness matter—like jet engine parts, fuel cells, medical tools, and satellite components.

Vacuum brazing produces joints that often require extensive post-cleaning.False

Vacuum brazing is flux-free, so there's no need for post-cleaning.

Vacuum brazing reduces distortion in delicate parts by applying even heat.Totta

The even heating in a vacuum furnace minimizes part warping.

Päätelmä

Vacuum brazing is a clean, precise, and powerful metal joining method. It’s essential in industries where quality, cleanliness, and strength are non-negotiable. From aerospace to medical, it delivers unmatched performance and reliability.