Extruded Aluminum Vs Cast Aluminum?

Aluminum is everywhere—but not all aluminum is the same. If you’re choosing between cast and extruded aluminum, the wrong choice can crack, warp, or fail under pressure.

Extruded aluminum is generally stronger and more ductile than cast aluminum due to its aligned grain structure and fewer internal defects.

Let’s break down what makes these two materials different—and when to choose one over the other.

Is extruded aluminum stronger than cast aluminum?

I’ve had customers surprised that two aluminum parts can look the same but perform very differently.

Yes, extruded aluminum is stronger than cast aluminum, especially in tensile and impact strength, due to its uniform grain structure and reduced porosity.

Strength Comparison

| Property | Extruded Aluminum | Cast Aluminum |

|---|---|---|

| Tensile Strength | Higher (e.g., 6061-T6) | Lower due to porosity |

| Impact Resistance | High | Moderate to low |

| Fatigue Life | Longer | Shorter |

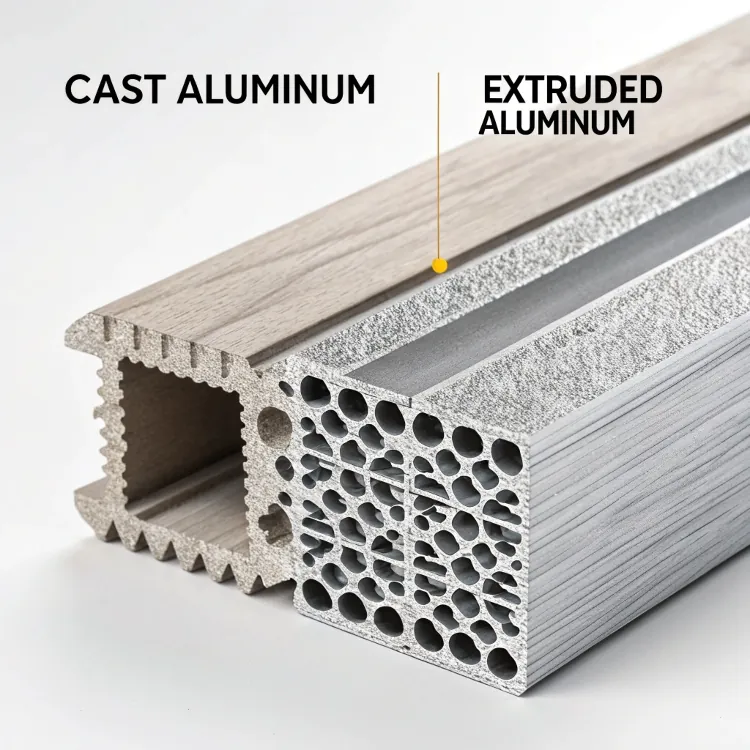

Casting creates a part by pouring molten metal into a mold, which can trap air or impurities. These lead to internal weaknesses. Extrusion, in contrast, forces solid aluminum through a die, aligning the grains and eliminating voids.

Extruded aluminum typically has higher tensile strength than cast aluminum.True

Extrusion aligns the metal's grain and reduces porosity, making it stronger.

Casting creates a stronger aluminum product than extrusion.False

Casting can introduce porosity and defects that reduce strength.

Why is extrusion better than casting?

Many clients ask me why we don’t just cast parts—it seems simpler. But performance says otherwise.

Extrusion is often better than casting because it provides superior mechanical properties, tighter tolerances, and better surface finish.

Advantages of Extrusion Over Casting

| Feature | Extrusion | Casting |

|---|---|---|

| Mechanical Strength | Excellent due to aligned grain | Moderate, often includes defects |

| Precision | High dimensional accuracy | Lower precision |

| Surface Finish | Smooth, can be anodized easily | Rough, needs post-processing |

| Lead Time | Shorter for medium-scale runs | Good for high-volume production |

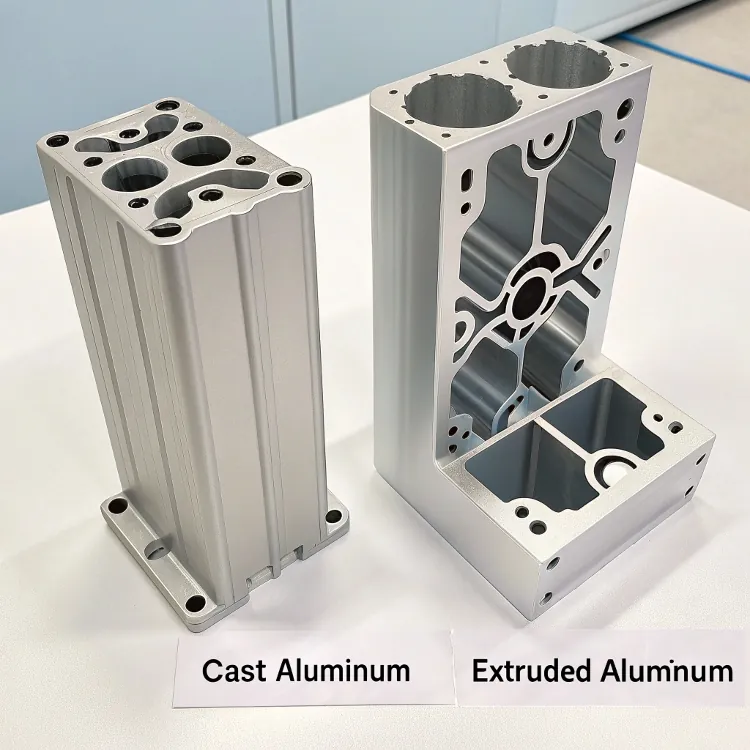

Casting works best for complex 3D shapes like engine blocks or housings. But if you need consistent quality, structural integrity, or long bars and profiles—extrusion wins.

Extruded aluminum can hold tighter tolerances than cast aluminum.True

The extrusion process allows for greater control over shape and dimensions.

Casting always produces better surface finish than extrusion.False

Casting surfaces are usually rough and require secondary finishing.

What is the difference between extruded aluminum and aluminum?

This question pops up often—especially from buyers unfamiliar with aluminum processing.

“Extruded aluminum” refers to aluminum that has been shaped through the extrusion process, whereas “aluminum” alone just describes the raw material.

How They Differ

| Term | Meaning |

|---|---|

| Aluminum | A metallic element or alloy |

| Extruded Aluminum | Aluminum that has been formed through a die to create specific shapes |

Aluminum can be processed in many ways: extruding, casting, forging, rolling. Each method changes its structure and performance. Extruded aluminum is just one form—but a very versatile one.

For example, the aluminum alloy 6063 is often used in extrusions for windows and frames. But the same alloy could be rolled or cast, with different results.

Extruded aluminum refers to a process, not a material.True

It's aluminum shaped by being pushed through a die.

All aluminum products are extruded.False

Aluminum can be extruded, cast, rolled, or forged, depending on the application.

Which is better aluminium or cast aluminium?

Sometimes clients think “cast aluminum” is a better grade or type. But these aren’t the same kind of thing.

Aluminum is the base metal, while “cast aluminum” is aluminum that has been processed through casting. Neither is inherently better—what matters is your application.

Choosing Between the Two

| Application Type | Recommended Process |

|---|---|

| Structural framing | Extruded aluminum |

| Complex 3D shapes | Cast aluminum |

| Lightweight assemblies | Extruded aluminum |

| Large batches of parts | Cast aluminum |

If your project needs strength, precise dimensions, or long, linear shapes—go with extruded aluminum. If you’re designing a complex housing or enclosure with internal cavities, casting may be the way to go.

It’s not about which is “better”—it’s about which fits your design.

Cast aluminum is a completely different material from aluminum.False

Cast aluminum is still aluminum, just shaped using a casting process.

The choice between aluminum and cast aluminum depends on the application.True

Each method suits different designs and performance needs.

Conclusion

Extruded aluminum and cast aluminum both have their strengths. Extrusion gives you better strength, cleaner surfaces, and more precise control. Casting shines in complex forms and high volumes. The key is knowing your application—and choosing accordingly.